High-voltage pulse drill bit and rock breaking experimental facility

A high-voltage electric pulse and drill bit technology, which is applied in the field of rock engineering, can solve the problems of high drilling cost, low drilling efficiency, and large drill bit wear, and achieve the effects of low drill bit wear, low noise and vibration levels, and high well wall quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0036] Embodiments of the present invention provide a high-voltage electric pulse drill bit and a rock-breaking experimental device.

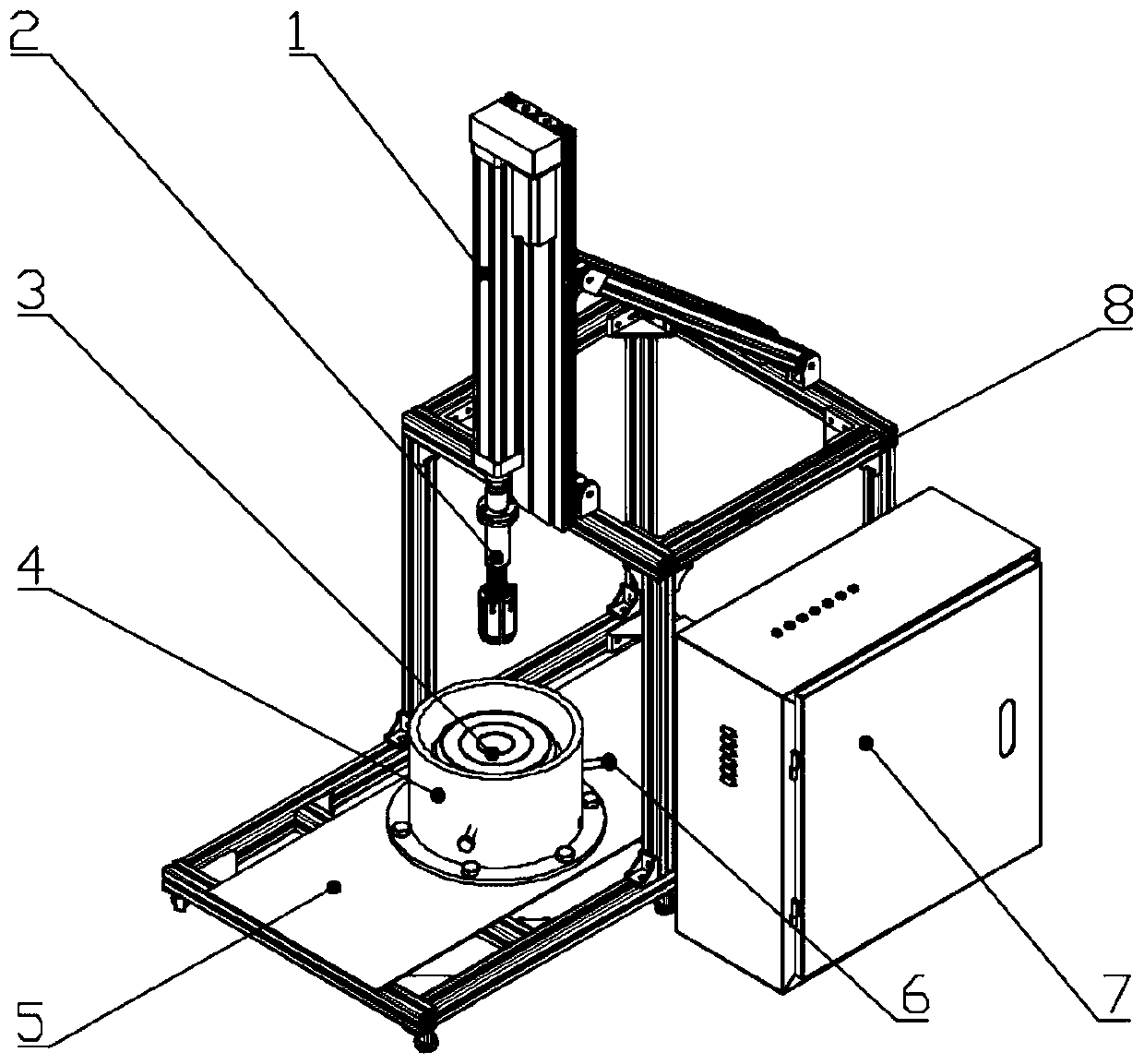

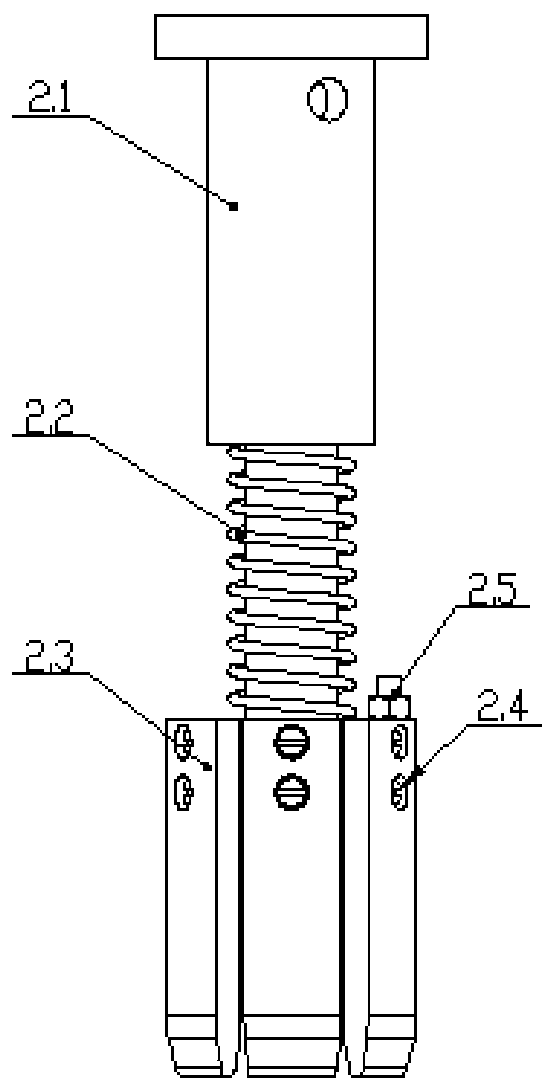

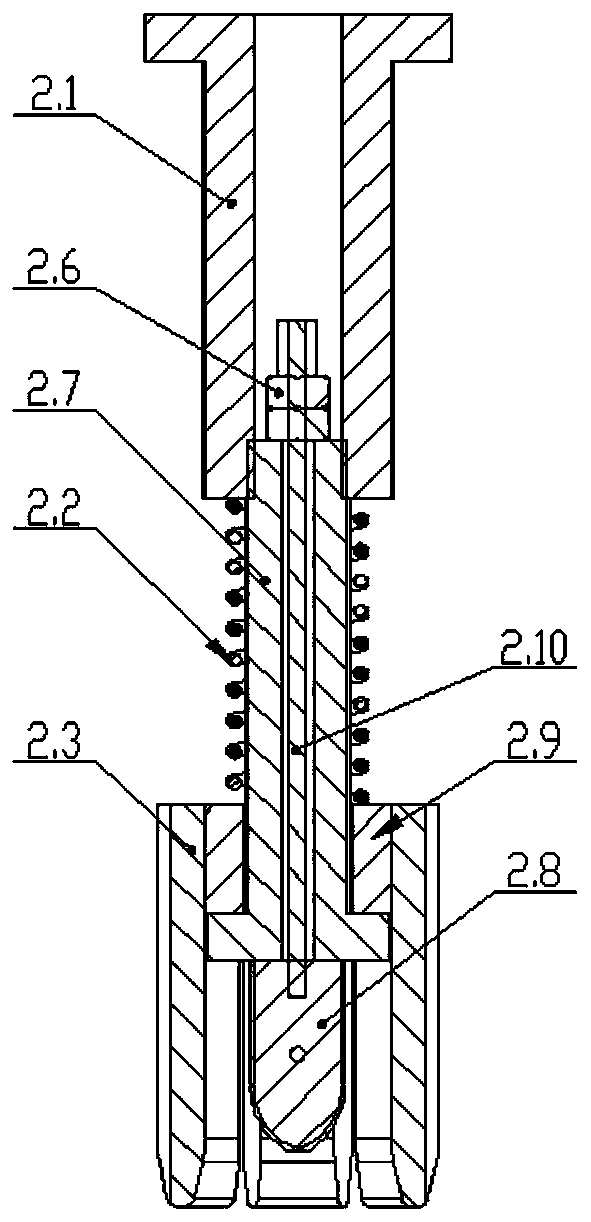

[0037] Please refer to Figures 1 to 4 , figure 1 It is the axonometric structure diagram of the high-voltage electric pulse drill bit and the rock-breaking experimental device in the embodiment of the present invention, figure 2 It is the external structure diagram of the high-voltage electric pulse drill bit in the embodiment of the present invention, image 3 is the internal structure diagram of the high-voltage electric pulse drill bit in the embodiment of the present invention, Figure 4 is the equivalent circuit diagram of the high-voltage pulse power supply in the embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com