Multi-electrode-pair electrical crushing drill bit and electrical crushing experiment device

An experimental device and multi-electrode technology, applied in the direction of the driving device, drill bit, measuring device, etc. for drilling in the borehole, can solve the problems that need to be further verified, and achieve the effect of simple structure, high reliability and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

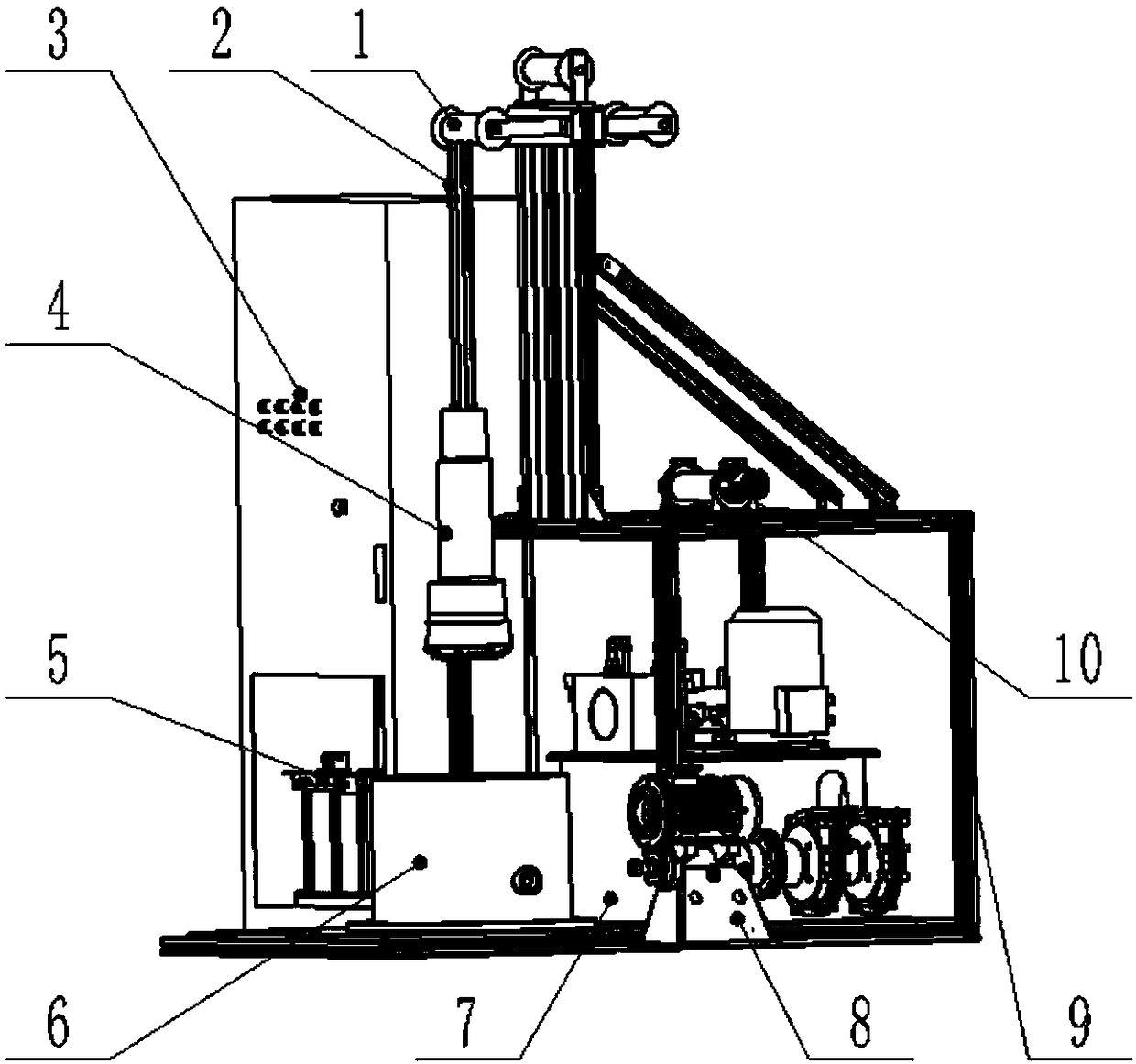

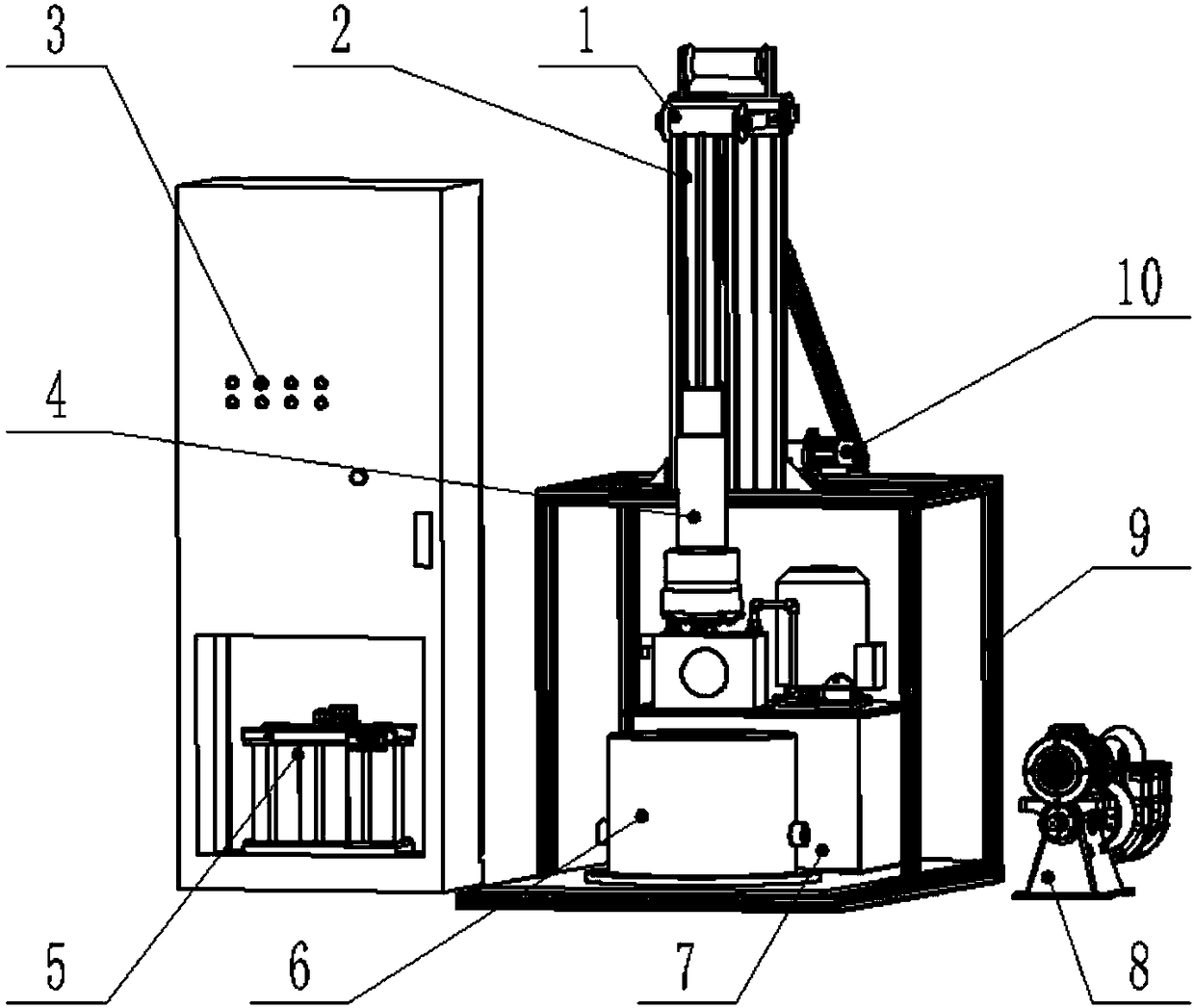

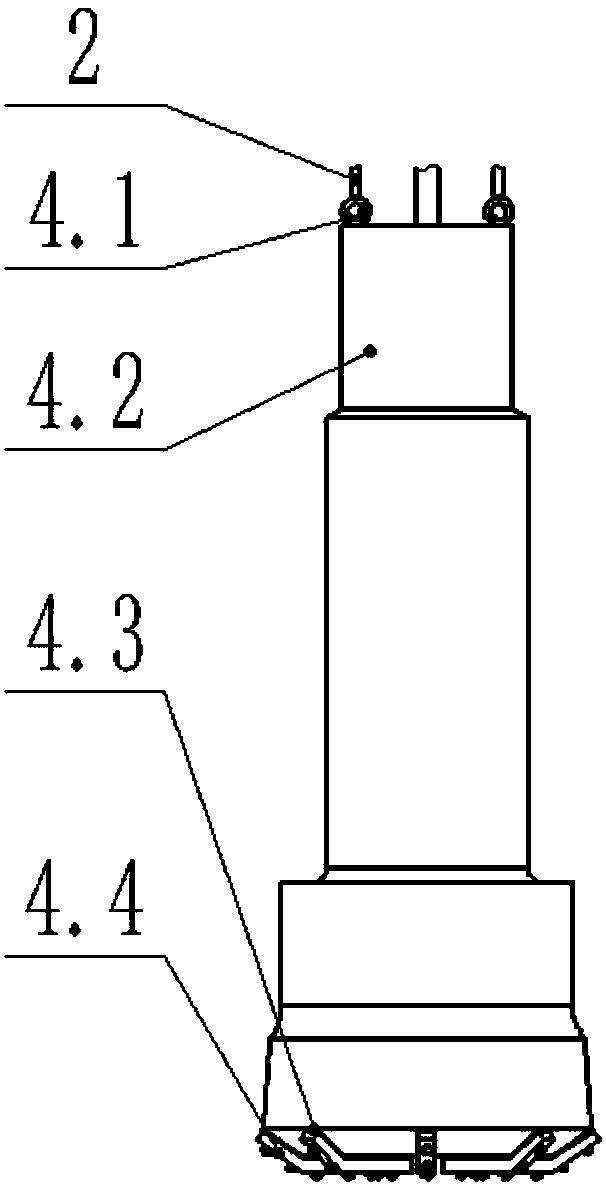

[0039] Embodiment 1: A multi-electrode pair electric crushing drill bit and electric crushing experimental device of the present invention, its structure is as follows figure 1 , 2, 3, 4, 5, 6, the electric crushing experimental device includes guide roller 1, steel wire rope 2, control device 3, multi-electrode pair electric crushing drill 4, pulse power supply 5, confining pressure cylinder assembly 6, hydraulic pump station 7, Inlet and outlet water pump 8, aluminum profile support 9 of experimental device, rope arrangement 10, and guide roller 1 are used to realize the guidance of steel wire rope 2 and cable 4.6. tight state; the wire rope 2 is used to lift and lower the multi-electrode pair electric crushing drill bit; the control device 3 is used to control the start and stop of the hydraulic pump station, the inlet and outlet water pump and the rope discharge device; the multi-electrode pair electric crushing drill bit 4 includes the lifting lug 4.1, the drill bit Arm ...

Embodiment 2

[0048] Embodiment 2: A multi-electrode pair electric crushing drill bit and an electric crushing experimental device of the present invention have the same structure as in Embodiment 1. When performing an electric pulse rock breaking experiment, the control device 3 controls the hydraulic pump station 7 to supply the confining pressure cylinder 6.1 Oil, add confining pressure to the rock sample 6.3, the control device 3 controls the rope discharge device 10 to lower the wire rope 2 and the cable 4.6, the multi-electrode pair electric crushing drill bit 4 descends, the control device 3 controls the inlet and outlet water pump 8 to realize the ionization of the water medium 6.2 in the confining pressure cylinder Circulation in the component 6, when the multi-electrode pair electric crushing drill bit 4 is in contact with the rock sample 6.3, the pulse power supply 5 is discharged, and the experimental research on the drill bit electrodes, insulating materials, drilling parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com