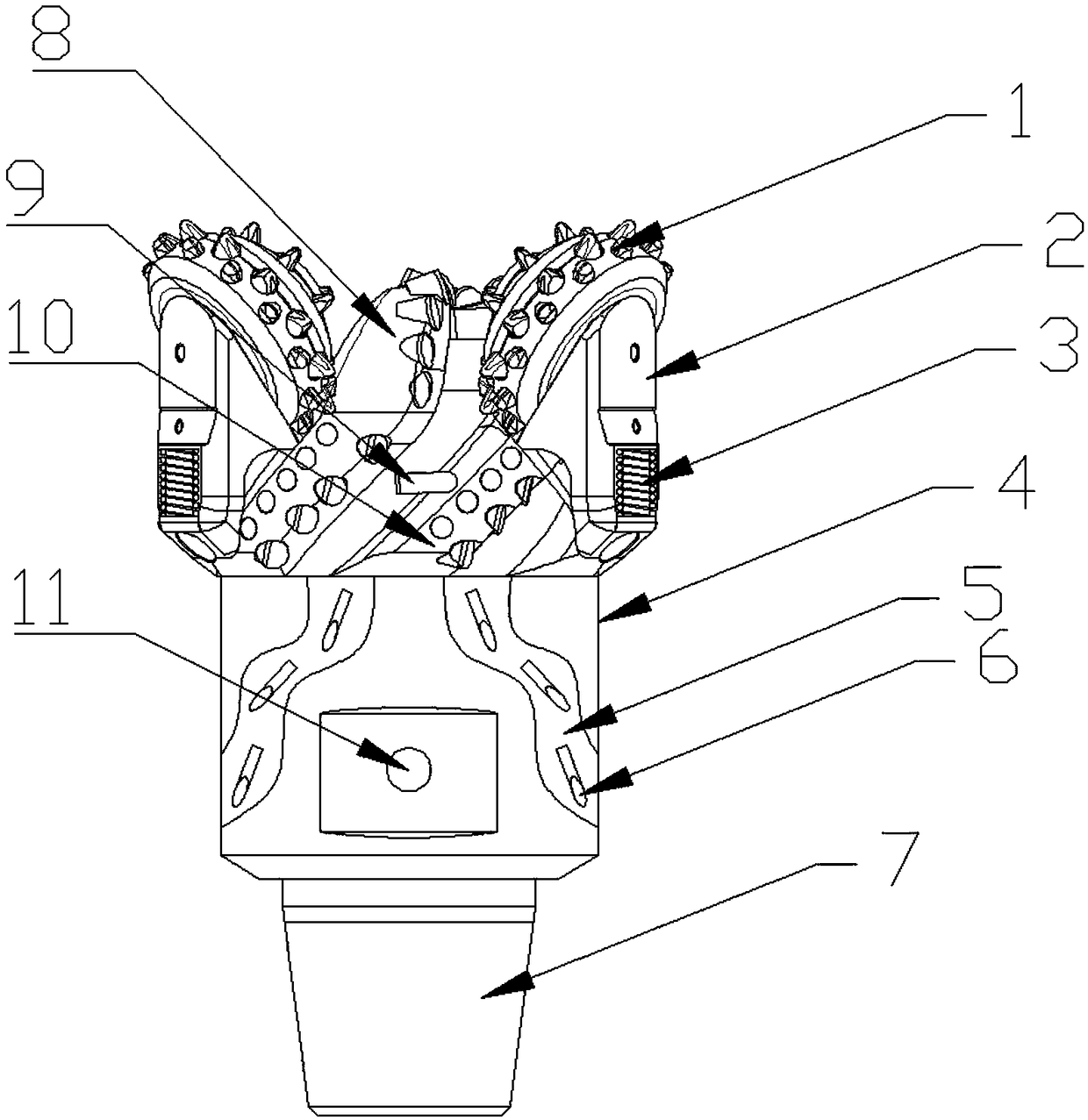

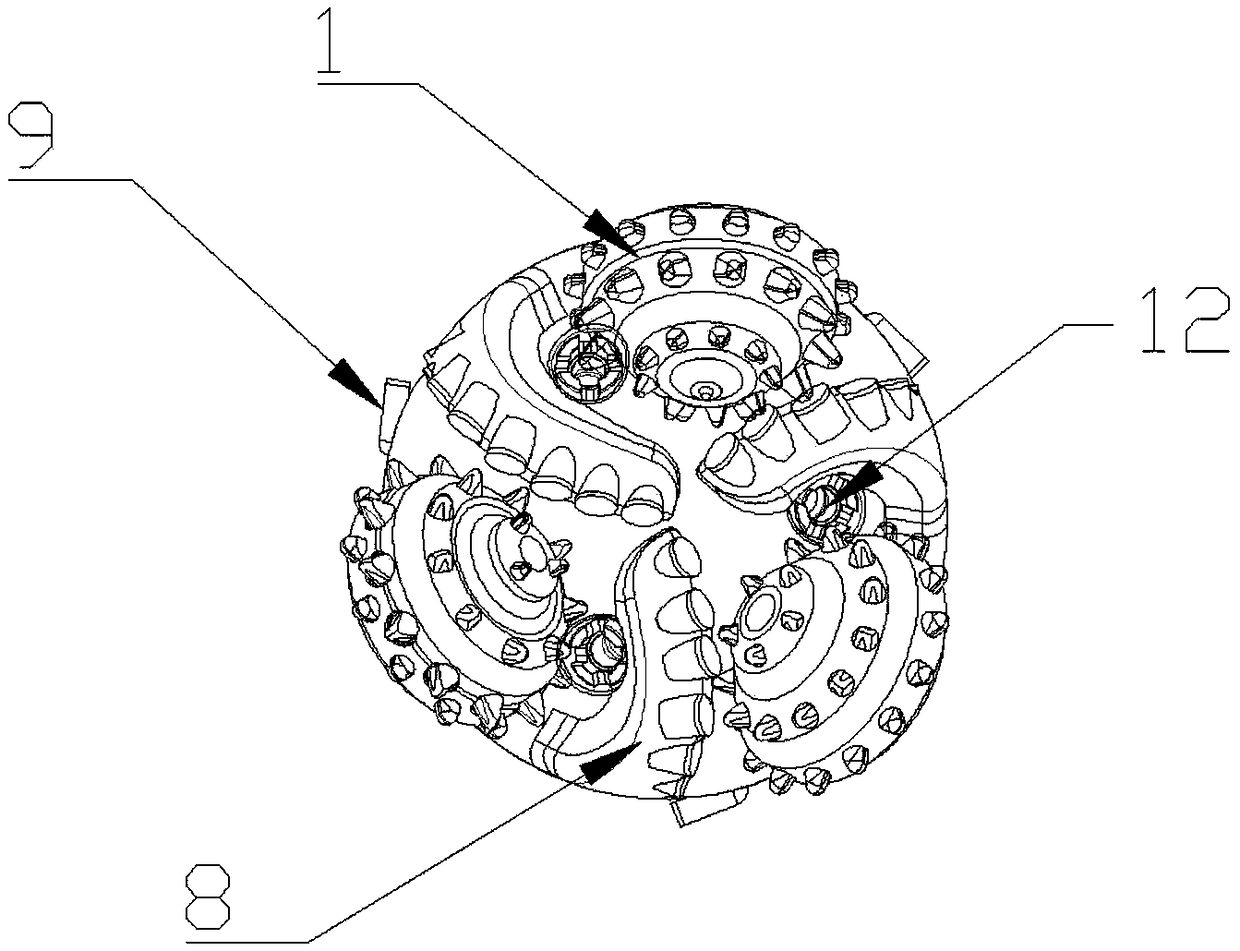

Three-blade PDC and tricone tooth combined drill bit

A combination drill bit and three-cone technology, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of instability and insufficient service life, and achieve the effects of prolonging service life, large cutting surface and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] As a basic example:

[0032] A combination drill bit with three-blade PDC and three-cone teeth, including a mounting part 7, which is provided with a screw thread, the mounting part 7 is connected with an intermediate shaft 4, and the intermediate shaft 4 is connected with a joint, which is characterized in that the joint is The tooth palm 2 is connected, the compression spring 3 is installed in the tooth palm 2, the upper end of the compression spring 3 is connected with the tooth palm 2, the lower end of the compression spring 3 is connected with the joint, and the joint is welded to the tooth palm 2, and the tooth palm 2 There is an empty slot for installing the compression spring 3 inside, the cone 1 is installed on the palm 2, there are three cones 2 and 1, and a PDC blade 8 is arranged between the cone 1, and the side of the joint Side blades 10 are provided at the positions of the PDC blades 8 .

[0033] The present invention uses the built-in compression spring...

Embodiment 2

[0035] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the arrangement direction of the side blades 10 is parallel to the arrangement direction of the PDC blades 8, and the side blades The length of the wing 10 is 1 / 2 of the PDC blade 8, and PDC teeth are installed on the side blade 10, and the PDC teeth are cylindrical PDC cutting teeth.

[0036] Further, the cylindrical PDC cutting teeth include cylindrical PDC cutting teeth of three sizes, and the three sizes of cylindrical PDC cutting teeth are mixed. The diameter of the tooth is 15-17mm, and the diameter of the small tooth is 13-15mm.

[0037] Compared with the PDC blade 8, the side blade 10 of the present invention is smaller, does not occupy too much space, makes the drill bit smaller, and has a better drilling effect, and the side blade 10 also uses PDC cutting teeth, which not only has diamond It has high hardnes...

Embodiment 3

[0039]This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, an auxiliary chip removal groove 5 is provided on the intermediate shaft 4, and the auxiliary chip removal groove 5 is connected with the side knife. The wings 10 are arranged in a staggered manner, the auxiliary flute 5 is curved, and the cross section of the flute is arc-shaped.

[0040] Further, a plurality of auxiliary jet ports 6 are opened in the auxiliary chip removal groove 5, and the auxiliary jet ports 6 communicate with the liquid pipes located in the intermediate shaft 4 and the installation part 7, and the liquid pipes are connected with nozzles 12 located on the joints , A convex cover for protecting the nozzle 12 is installed on the nozzle 12 .

[0041] The auxiliary chip removal groove 5 of the present invention can discharge the broken rock and broken soil cut out by the side blades 10 on the side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com