Impact voltage rock breaking combined drilling tool for improving mechanical drilling speed of hard stratum

An impulse voltage, combined drilling tool technology, applied in the direction of electromechanical devices, electric components, control mechanical energy, etc., can solve the problems of low cost, high drilling efficiency, large drill bit wear, etc., to achieve low cost, high drilling efficiency, and not easy to wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

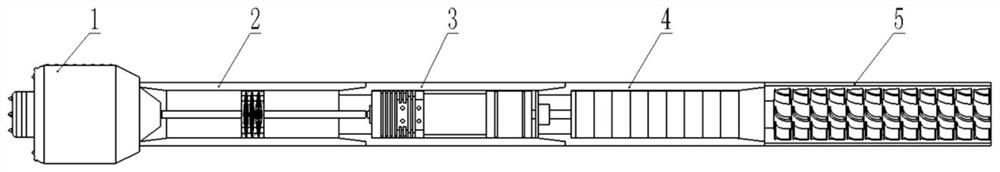

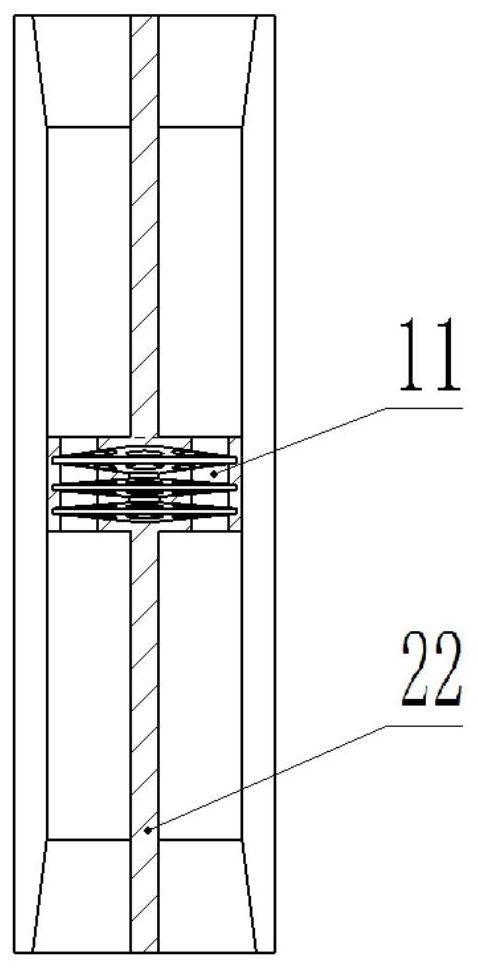

[0020] Depend on Figure 1 to Figure 6 As shown, a combination drilling tool for impact voltage rock breaking for improving the mechanical rate of penetration in hard formations, including a drill bit, the drill bit is an impact voltage rock breaking drill bit 1, and the upper end of the impact voltage rock breaking bit 1 is sequentially arranged from bottom to top. Connect the mud current casing 2, the impulse voltage generator short circuit 3, the lithium battery short circuit 4, and the downhole power generation short circuit 5.

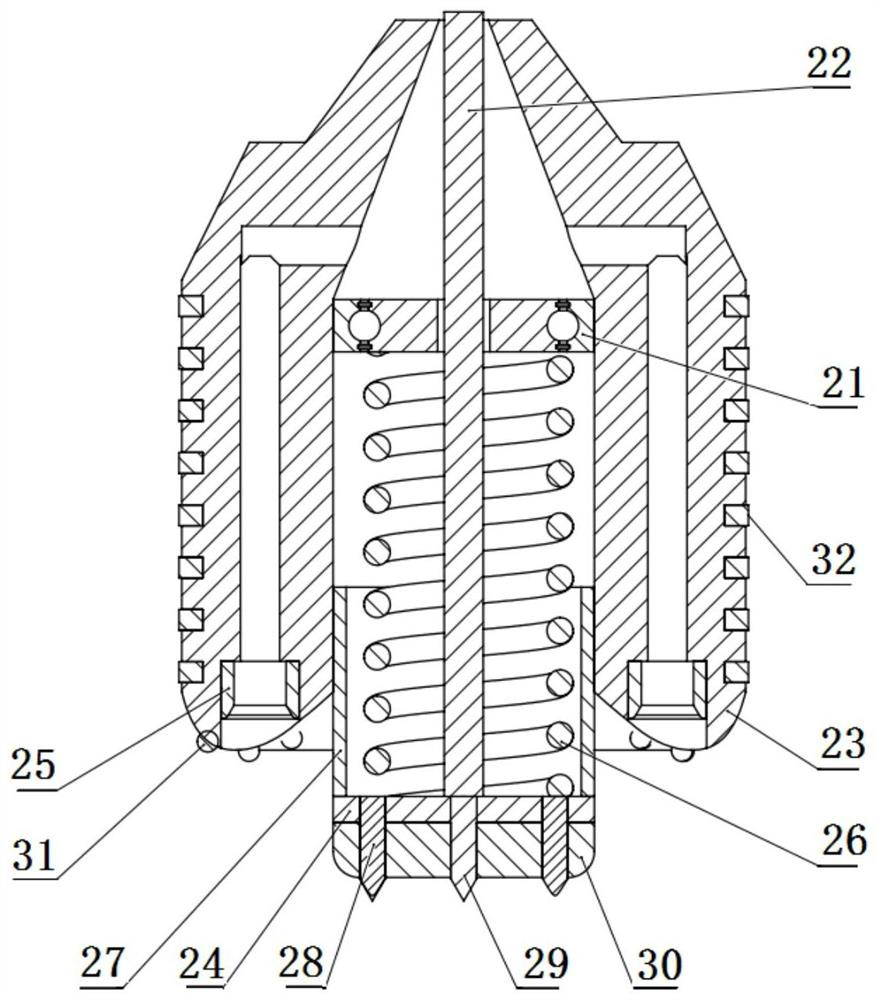

[0021] The impact voltage rock breaking drill bit 1 includes a drill bit housing 23, the drill bit housing 23 is made of PDC (PDC is a polycrystalline diamond composite sheet) material, the upper end of the drill bit housing 23 is provided with an insulating centralizing bearing 21, and the lower end is connected with a spring Cover 27, spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com