Rock drillability determining method capable of determining drill bit wear

A measurement method and drill bit technology, which are applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of prolonged drilling cycle, general effect, analysis of drill bit wear, etc., and achieve the effect of improving test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

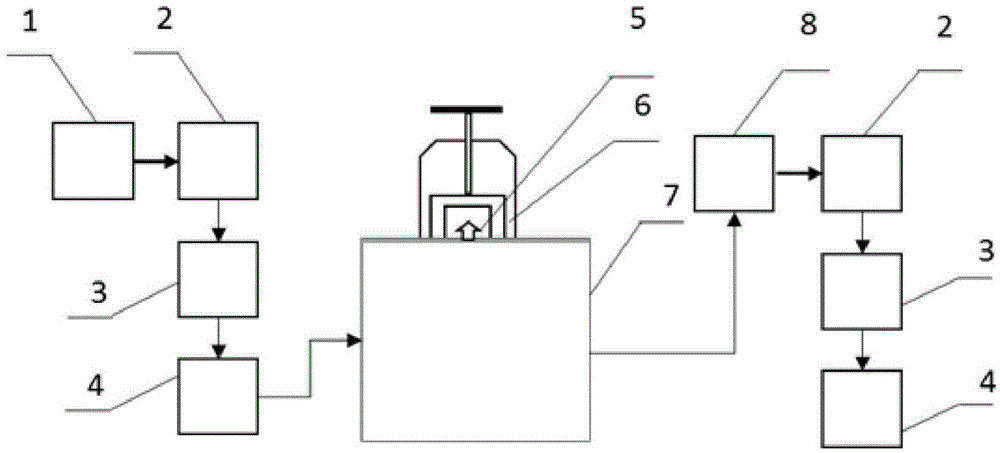

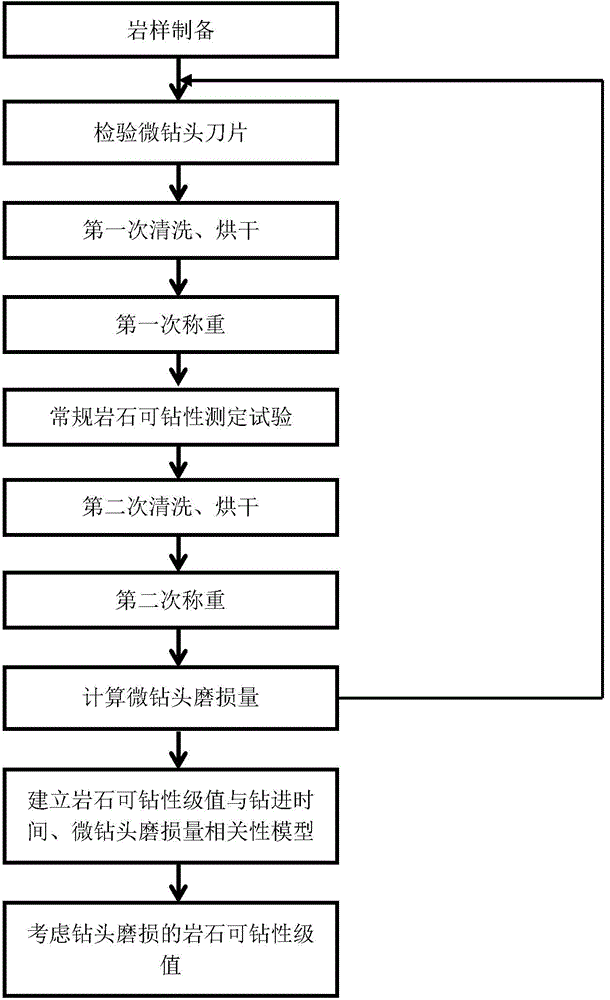

[0027] Such as figure 1 As shown, the device part involved in the present invention has fully utilized the existing rock drillability measuring device 7, and the difference is that the cleaning and weighing of the micro-drill blades before and after the test have respectively adopted higher precision. Ultrasonic cleaner 2 and electronic balance 4. The operation process of the device is as follows: after the micro-drill blade 1 for rock drillability measurement is cleaned by an ultrasonic cleaner 2, dried in a drying box 3 and weighed by an electronic balance 4, relevant data is recorded, and then the micro-drill bit 5 for rock drillability measurement And the test rock sample 6 is installed in the rock drillability measuring device and carries out the grinding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com