Method for detecting micro drill-bit wear degree, method using the said method and drilling device

A micro-drill, wear-level technology, used in drilling/drilling equipment, components of boring machines/drilling machines, boring/drilling, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0040] Due to the friction between the micro-drill and the material of the PCB board during the drilling process, the material of the drill bit is consumed to a certain extent, causing wear and tear, which makes the cutting of the bit dull; and the blunt micro-drill makes the friction more intense, and the friction is more intense , the easier it is to aggravate the wear, the more heat is generated, and the higher the temperature is, the wear of the drill bit is closely related to the temperature of the drill bit. Therefore, we can detect the wear of the micro drill bit at this time by capturing the temperature of the micro drill bit state.

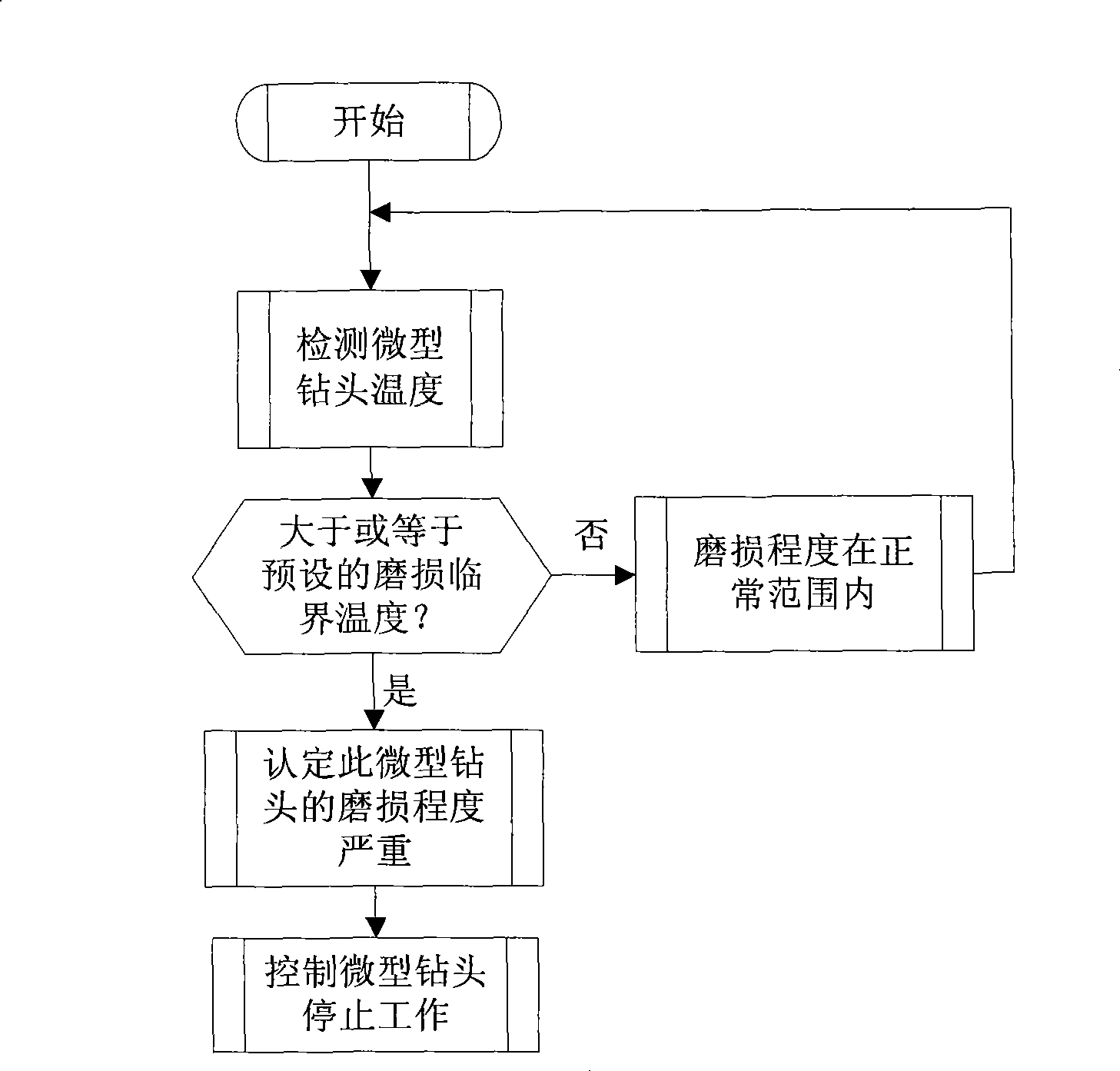

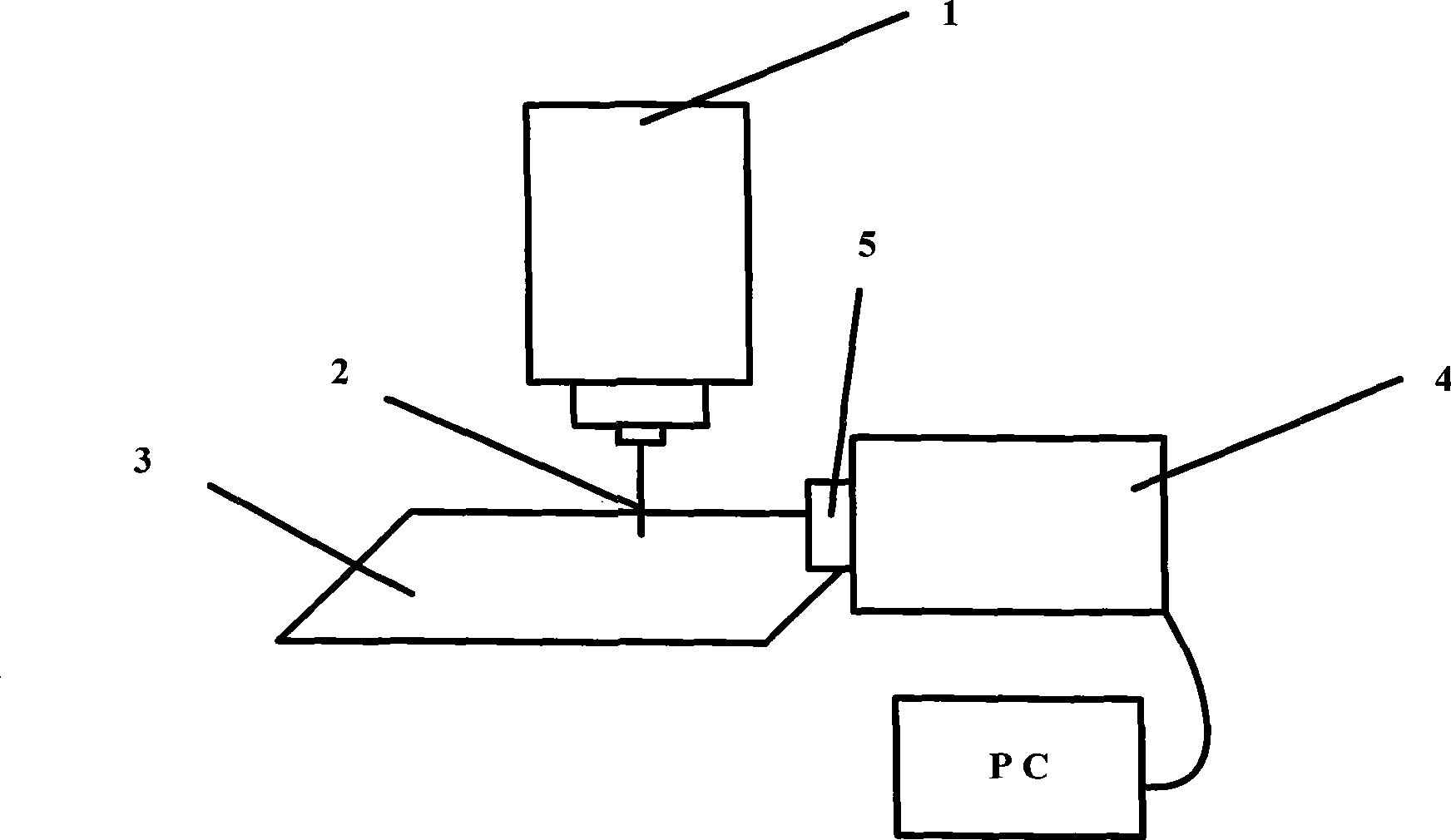

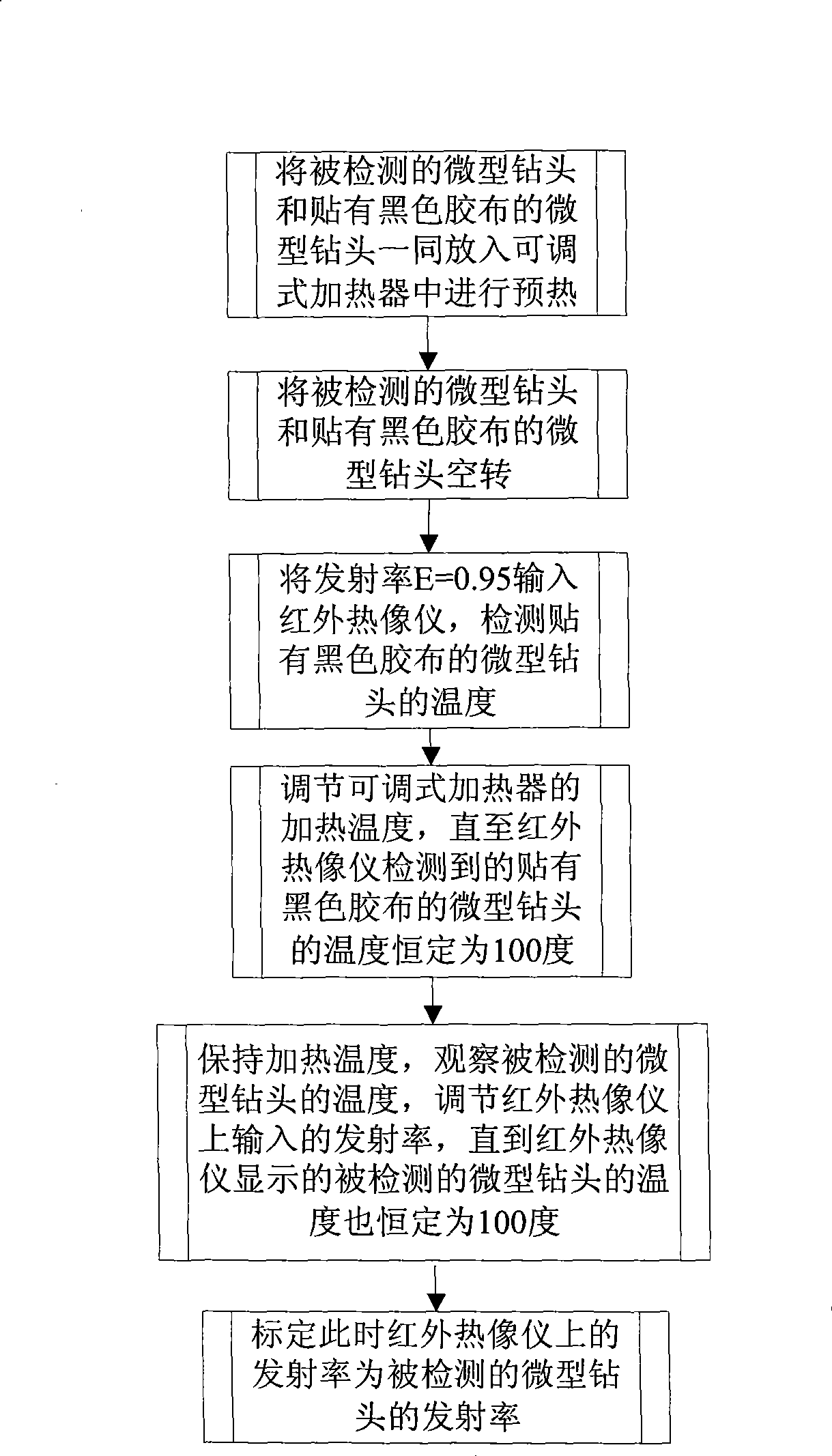

[0041] The method for detecting the degree of wear of the micro-drill of the present invention, such as figure 1 and figure 2 shown, including the following steps:

[0042] A: Detect the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com