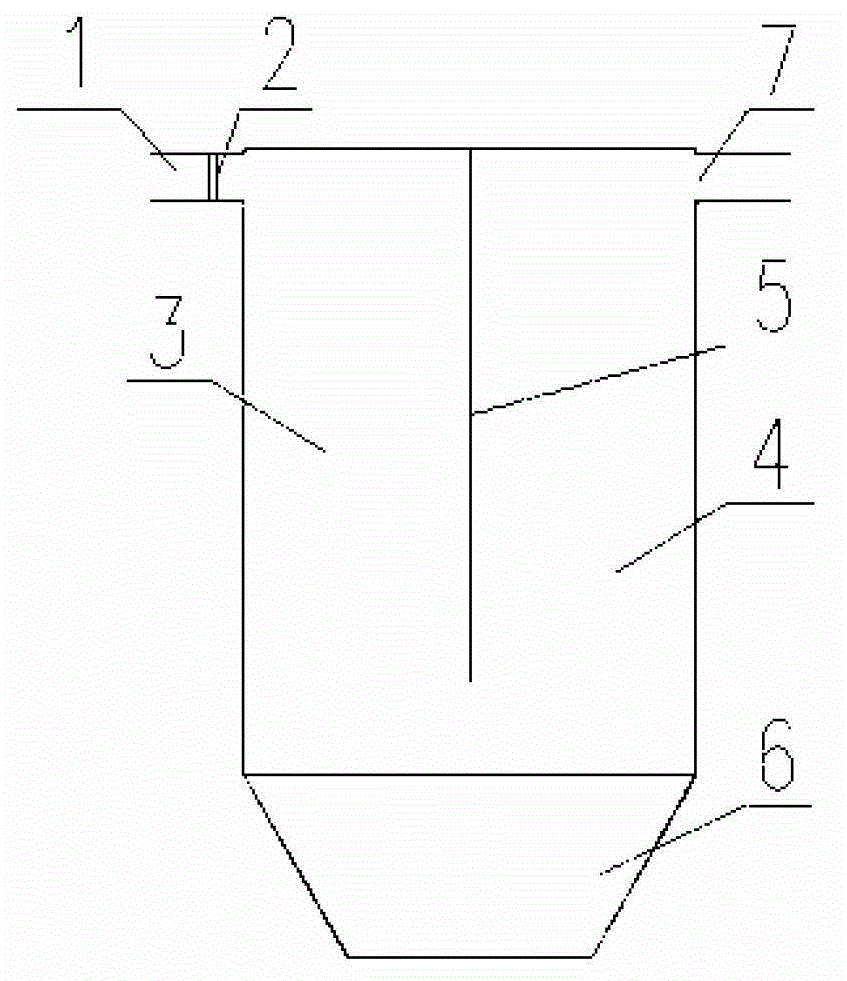

Semi-dry-process desulfurization apparatus

A semi-dry desulfurization and equipment technology, which is applied in the field of environmental engineering, can solve the problems of heavy dust collector load and high energy consumption of semi-dry desulfurization equipment, and achieve the effects of reducing load, reducing circulating ash and increasing reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention divides the absorption tower into two parts by dividing the absorption tower into two parts. On the premise that the floor area of the absorption tower remains unchanged, the contact time between the flue gas and the desulfurizer is greatly increased, the desulfurization efficiency is improved, and the pressure loss of the dust collector is reduced. The power consumption of the follow-up main exhaust fan is reduced, which greatly saves power consumption and maintenance and repair costs. The present invention is provided with a deflector in the entrance of the absorption tower, so that the distribution of the flue gas flow field is more uniform, the mixing of the flue gas and the desulfurizer is more sufficient, and the desulfurization efficiency is obviously improved. The concentration of circulating ash in the dense phase chamber of the present invention is relatively high, and about 75% of the desulfurization reaction is completed in the dense p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com