Automatic production line of wooden trays

An automatic production line and wooden pallet technology, applied in wood processing equipment, manufacturing tools, etc., can solve the problems of high production cost, complicated production process and low production efficiency of wooden pallet processing equipment, and reduce production cost and floor space , Simplify the production process and improve the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

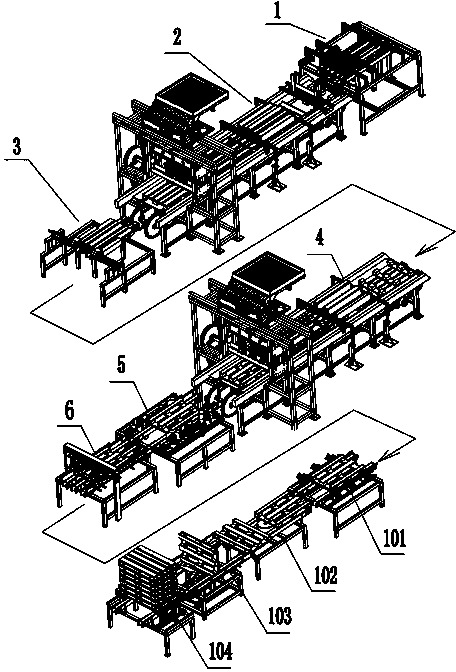

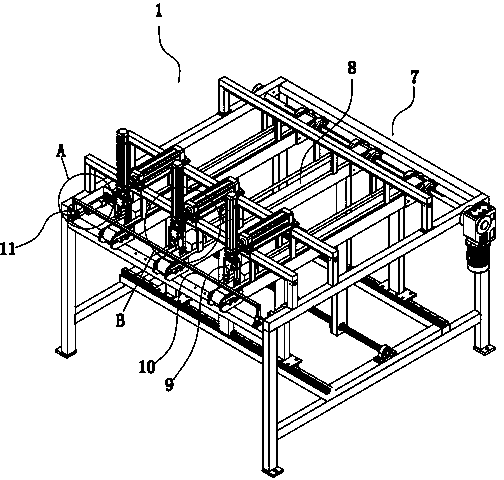

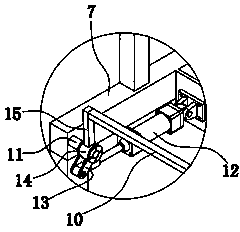

[0068] Such as figure 1 As shown, an automatic production line for wooden pallets sequentially includes a wooden pier feeding device 1, a wooden pallet front component processing device 2, a first turning device 3 for turning over wooden pallet front components, a wooden pallet back component processing device 4, a wooden pallet Four-corner chamfering device 5 , wooden pallet bottom plate chamfering device 6 , wooden pallet ironing device 101 , wooden pallet rotating device 102 , second turning device 103 and wooden pallet stacking device 104 for turning over wooden pallets. The four-corner chamfering device for wooden pallets is used to chamfer the four right angles of wooden pallets. The wooden pallet bottom plate chamfering device is used for chamfering the side of the wooden pallet bottom plate. Wooden tray ironing device performs hot sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com