Novel ceramic membrane tube with catalytic function and preparation method of novel ceramic membrane tube

A ceramic membrane tube and functional technology, which is applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems that the catalyst cannot be replaced according to the needs, the service life of the membrane tube is reduced, and the catalytic function of the membrane tube is reduced. The preparation method is simple and controllable, the service life is prolonged, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

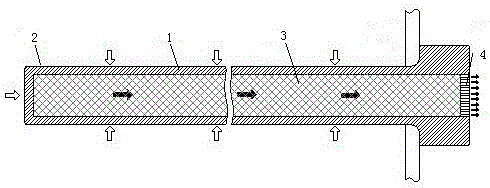

[0031] Embodiment 1: A new type of ceramic membrane tube with catalytic function, including a support body 1 with an open end, a separation membrane 2 coated on the surface of the support body 1, a catalytic cotton 3 filled in the inner cavity of the support body 1, and a sealing The honeycomb ceramic baffle plate 4 used to block and compress the catalytic cotton 3 at the opening of the support body 1 . The ceramic filter tube support body 1 has a porosity of 30%~45%, and a bending strength of ≥18MPa. The average pore diameter of the separation membrane 2 is 1-20 μm. The honeycomb ceramic baffle 4 is made of cordierite, the shape is hexagonal, and the number of holes is 5~20 / cm 2 , The thickness of the honeycomb ceramic baffle plate 4 is 1~2cm.

Embodiment 2

[0033] The catalytic function ceramic membrane tube of the present invention and preparation method thereof comprise the following steps:

[0034] 1. Preparation of ceramic membrane tube support body.

[0035] 1.1 Weigh 84.5wt% of silicon carbide powder with a fineness of 60 mesh, 3.0wt% of Suzhou soil powder with a fineness of 250 mesh, 3.0wt% of silicon micropowder with a fineness of 250 mesh, 1.5wt% of talcum powder with a fineness of 250 mesh, and 4.0wt% of wood chips with a fineness of 250 mesh % and a concentration of 10wt% PVA solution 4.0wt%, mixed and granulated to make a dry-pressed billet.

[0036] 1.2 After the dry-pressed blank is isostatically pressed under 35MPa pressure, it is dried in an oven at 80°C for 16 hours, and then the dried membrane tube body is fired in a kiln, and the temperature is raised to 1.5°C / min. 1350°C, and kept at the highest temperature for 3 hours, then cooled to room temperature with the furnace to obtain a ceramic membrane tube support...

Embodiment 3

[0054] The catalytic function ceramic membrane tube of the present invention and preparation method thereof comprise the following steps:

[0055] 2. Preparation of ceramic membrane tube support body.

[0056] 1.1 Weigh 82.5wt% of silicon carbide powder with a fineness of 100 mesh, 4.0wt% of Suzhou soil powder with a fineness of 250 mesh, 4.0% of silicon micropowder with a fineness of 250 mesh, 2.0wt% of talcum powder with a fineness of 250 mesh, and wood chips with a fineness of 100 mesh 2.0wt% and 5.5wt% PVA solution with a concentration of 10wt% were mixed and granulated to obtain a dry-pressed billet.

[0057] 1.2 After the dry-pressed billet is isostatically pressed under 50MPa pressure, it is dried in an oven at 70°C for 24 hours, and then the dried membrane tube body is fired in a kiln, and the temperature is raised to 0.5°C / min. 1320°C, and kept at the highest temperature for 5 hours, then cooled to room temperature with the furnace to obtain a ceramic membrane tube s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com