High-speed cigarette sorting system

A sorting system, high-speed technology, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of affecting distribution costs, impersonalization, and manual participation, so as to improve the sorting ability, improve the degree of automation, The effect of high-speed sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

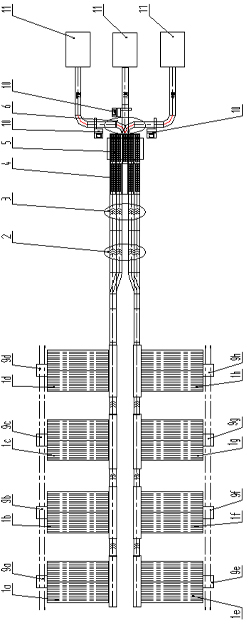

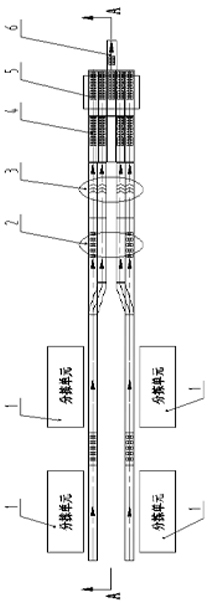

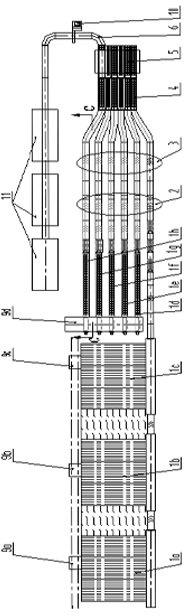

[0020] Such as figure 1 , figure 2 As shown, the present invention includes several sorting units 1 (at least two sorting units, and four sorting units in this embodiment), and a parallel conveyor composed of at least two conveying lines arranged downstream of the sorting units in sequence. Conveyor line 2, diversion unit 3, buffer unit 4, confluence unit 5 and exit conveyor 6. The distribution unit 3 is a swing conveyor whose tail end can swing to different height positions. The buffer unit 4 is composed of at least two layers (three layers in this embodiment) of conveyors, has the function of buffering and conveying materials, and has the number of material conveying channels matching that of the confluence unit. A movable baffle 8 for blocking materials is arranged at the channel exit of the buffer unit. The swing conveyor can swing to meet each level of the buffer unit. The swing conveyor includes at least two conveying channels, and the number of conveying channels s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com