Parallel flow-combining machine

A technology of conveyor belts and baffles, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of large area for conveying and confluence, and achieve fast confluence speed, small area and large confluence capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

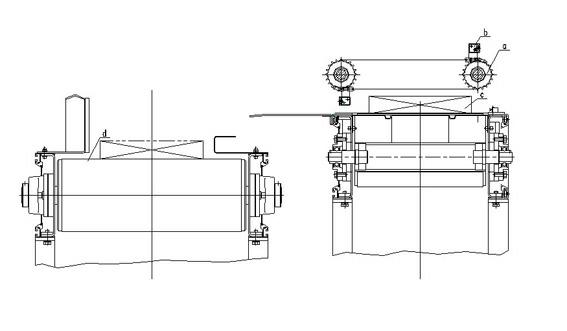

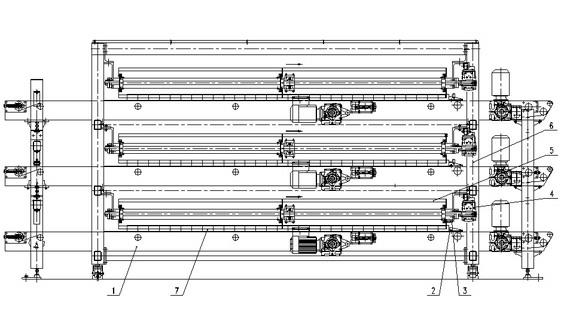

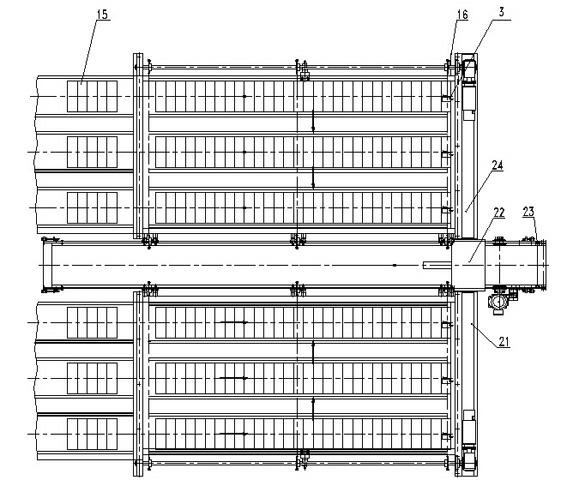

[0016] Such as figure 2 , image 3 , Figure 4 Shown, the present invention is made up of left confluence device 24, right confluence device 21, center belt machine 14 and electric device etc. Comprising a left confluence device 24 and a right confluence device 21 installed on the legs 6, a central belt conveyor 14 with a feeding direction perpendicular to the discharge direction of the confluence device and docked with the confluence device is arranged between the left confluence device and the right confluence device; Both the left confluence device and the right confluence device include at least two layers of confluence mechanisms 4 and are arranged symmetrically, and the number of layers of the central belt machine is the same as that of the confluence device. In this embodiment, the confluence mechanism and the central belt machine are all provided with three layers. At least two confluence channels are provided on each confluence mechanism of each confluence device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com