Method for separating zinc and indium and iron from indium-enriched high-iron high-zinc calcine through reduction-magnetic separation

A technology of enriching indium, high iron and zinc, and magnetic separation, applied in the field of mineral processing, can solve the problems of complex purification process, lower metal recovery rate, loss of zinc and indium, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: Indium-rich high-iron-zinc calcine from a certain place in Yunnan, its main chemical composition is:

[0029] components

Zn

Fe

In

Cu

Pb

sn

CD

Sb

S

As

SiO 2

CaO

Contentwt / %

50.04

24.11

0.12

0.32

0.29

0.21

0.21

0.12

1.29

0.35

1.12

0.71

[0030] The main phases are:

[0031] Phase

ZnO

ZnFe 2 o 4

Fe 2 o 3

ZnS

SiO 2

other

total

Ratio / wt%

54.34

23.41

18.96

0.04

1.12

2.13

100

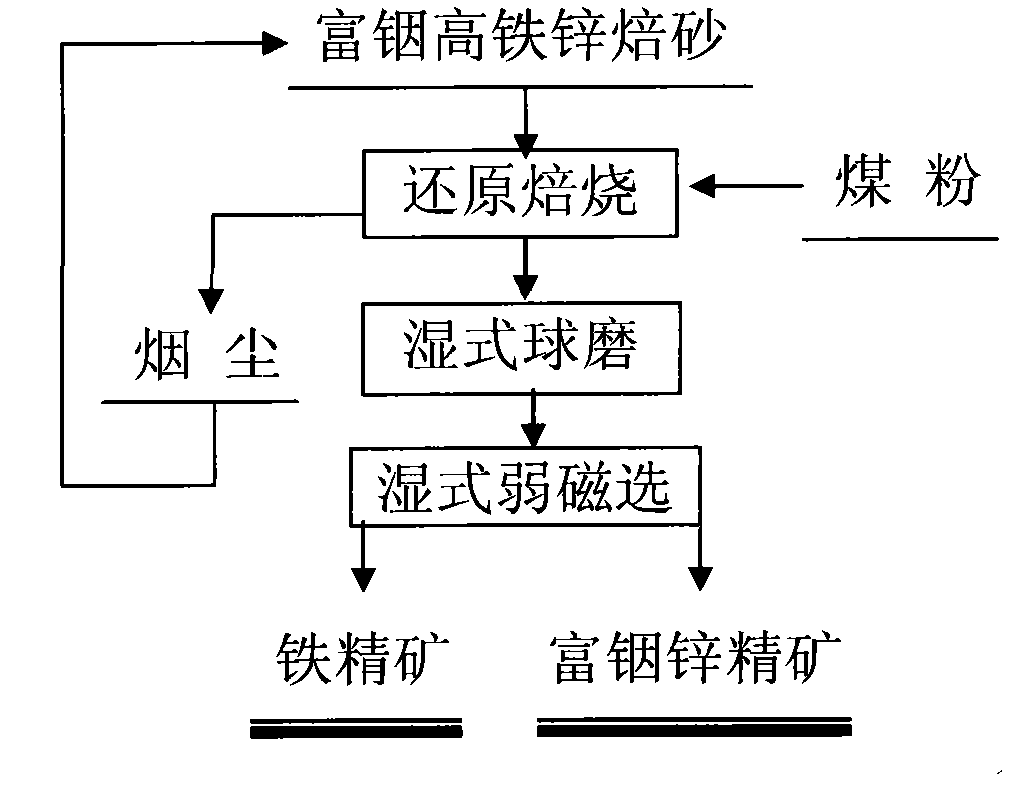

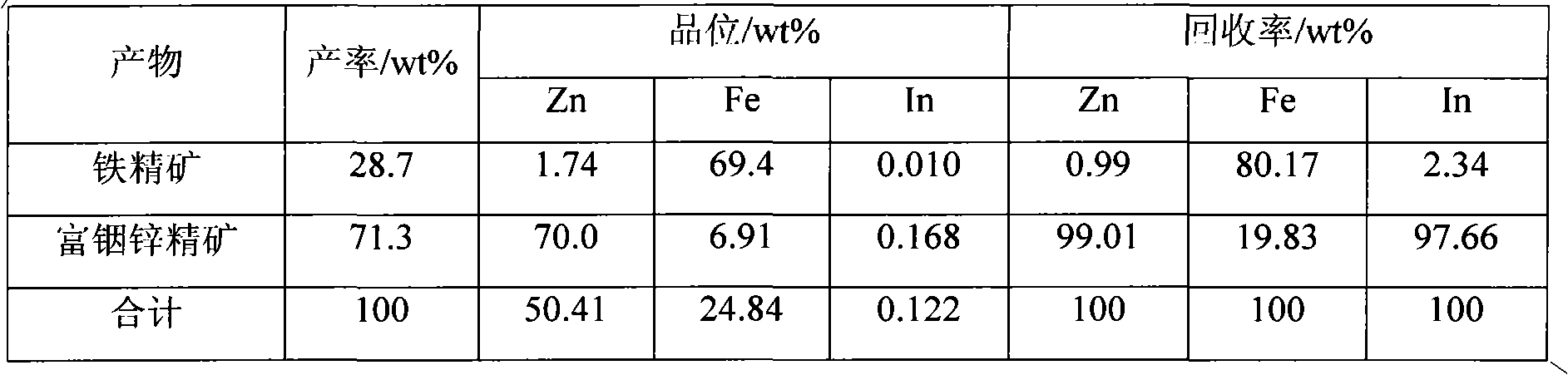

[0032] Reduction roasting - magnetic separation technology process is:

[0033] (1) Add the above-mentioned indium-rich high-iron-zinc calcine into the Φ2.8×36m rotary kiln at a feeding rate of 12.75t / h, and feed calcine quality 5wt% gas into the rotary kiln through the gas generator at the rotary kiln mouth , control the temperature in the kiln at 480-510°C, and r...

example 2

[0040] Example 2: Indium-rich high-iron-zinc calcine from a certain place in Yunnan, its main chemical composition is:

[0041] components

Zn

Fe

In

Cu

Pb

sn

CD

Sb

S

As

SiO 2

CaO

Content / wt%

54.12

20.21

0.10

0.43

0.41

0.20

0.45

0.11

1.33

0.31

1.68

0.75

[0042] The main phases are:

[0043] Phase

ZnO

ZnFe 2 o 4

Fe 2 o 3

ZnS

SiO 2

other

total

Ratio / wt%

59.97

21.81

14.45

0.05

1.68

2.04

100

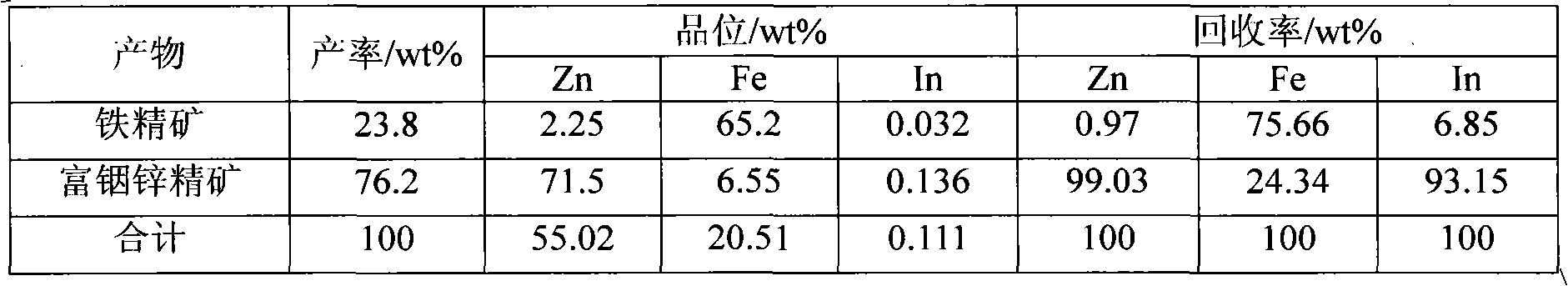

[0044] Reduction roasting - magnetic separation technology process is:

[0045] (1) Add the above-mentioned indium-rich high-iron-zinc calcine into the Φ2.8×36m rotary kiln at a feeding rate of 12.75t / h, and feed calcine mass 3wt% gas into the rotary kiln through the gas generator at the rotary kiln mouth , control the temperature in the kiln at 520-550°C, reduce t...

example 3

[0052] Example 3: Indium-rich high-iron-zinc calcine from a certain place in Guangxi, its main chemical composition is:

[0053] components

Zn

Fe

In

Cu

Pb

sn

CD

Sb

S

As

SiO 2

CaO

Content / wt%

51.12

22.03

0.15

0.41

0.42

0.23

0.39

0.10

1.27

0.32

1.91

0.82

[0054] The main phases are:

[0055] Phase

ZnO

ZnFe 2 o 4

Fe 2 o 3

ZnS

SiO 2

other

total

Ratio / wt%

56.37

21.39

17.32

0.04

1.91

2.97

100

[0056] Reduction roasting - magnetic separation technology process is:

[0057] (1) Add the above-mentioned indium-rich high-iron-zinc calcine into the Φ2.8×36m rotary kiln at a feeding rate of 12.75t / h, and feed 8wt% gas of calcine quality into the rotary kiln through the gas generator at the rotary kiln mouth , control the temperature in the kiln to 450-480°C, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com