Garbage classifying, recycling and treating system and garbage classifying and recycling method

A technology of garbage sorting and recycling, applied in grain processing, recycling technology, mechanical material recycling, etc., can solve the problems of high energy consumption, complex sorting process, and inability to achieve crushing, achieving less equipment, good effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

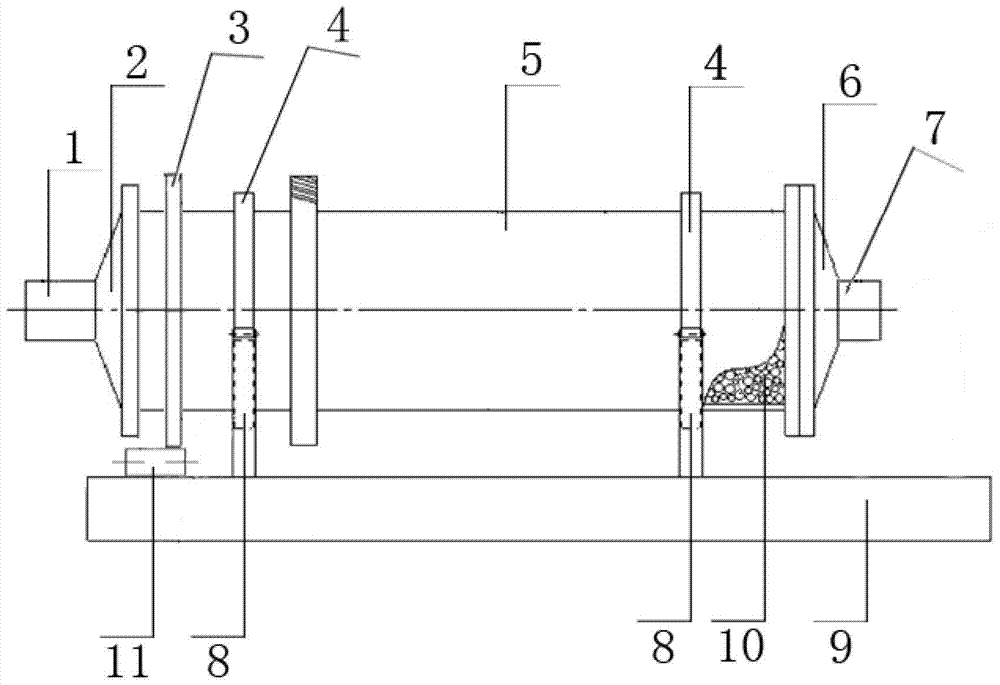

[0053] like figure 1 -4 and Figure 8 As shown, it is the second embodiment of the crushing device of the present invention. This embodiment only describes in detail the different parts from the first embodiment, and the same parts will not be repeated.

[0054] This embodiment provides a garbage crushing system, which includes an input material port 36 and an output material port 37, and includes two driving devices, one of which is used to drive the second crushing device to rotate as a housing driving device, and the other One is a rotating crushing roll drive for driving the crushing roll 32 in the first crushing device.

[0055] As shown in Fig. 7, a meniscus-shaped crushing plate 34 is arranged inside the box 31 of the first crushing device according to the embodiment of the present invention, and the concave portion of the crushing plate 34 faces the crushing roller 32, which is fixed to the rotating On the shaft 33, a portion of the crushing plate 34 is fixed to the ...

no. 1 example

[0060] like Figure 9 As shown in -12, the shape of the garbage sorting pool 4 in the embodiment of the present invention is not limited, it can be a regular shape, it can also be an irregular shape, it can be a circle, an ellipse, a quadrilateral or a polygon, etc., the present invention In the embodiment, the first side wall 412 is defined as the feed inlet end, and the second side wall 413 is defined as the corresponding end of the first side wall, so as to describe the embodiment of the present invention. The second side wall 413 of the embodiment of the present invention is far away from the first side wall 412, and the bottom of the sorting tank is an inclined structure, which may be that the bottom of the first side wall is lower than the bottom of the corresponding second side wall 413 More specifically, the bottom of the sorting tank is at least an inclined structure with an angle of 5-30 degrees, preferably 15 and 20 degrees; in order to facilitate the accumulation a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com