Pollution-free flotation separation method for copper-lead-zinc polymetallic ore

A separation method and polymetallic ore technology, applied in flotation, solid separation, etc., can solve the problems of difficult separation of copper and zinc-sulfur minerals, difficult handling of dichromate ions, difficult suppression of zinc-sulfur, etc., and achieve good separation effect , High recovery rate and efficient recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

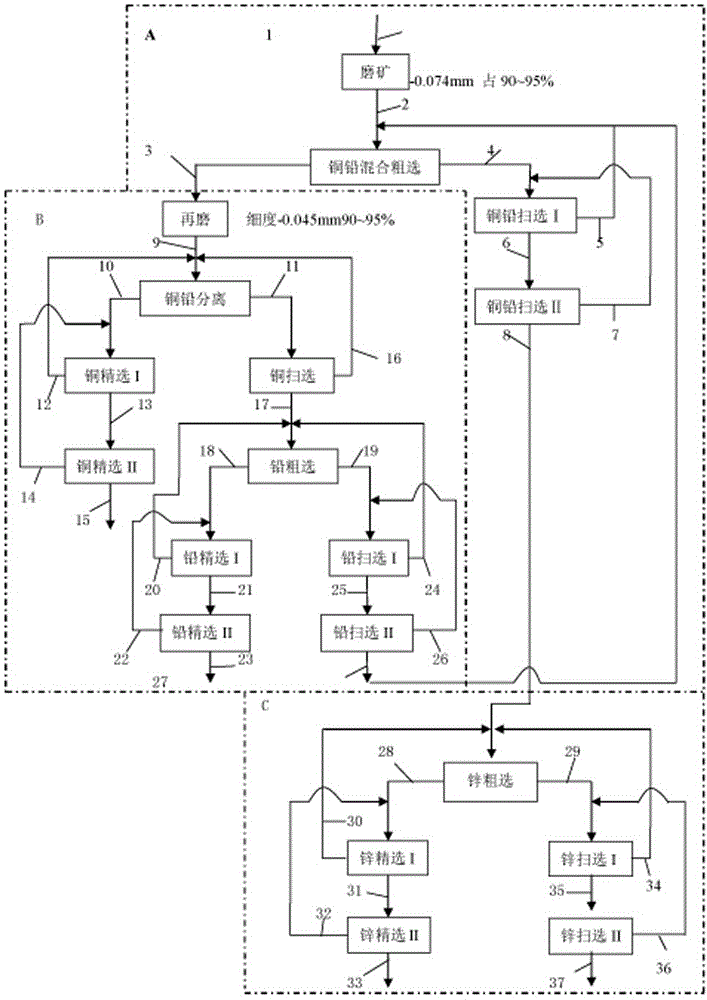

Method used

Image

Examples

Example

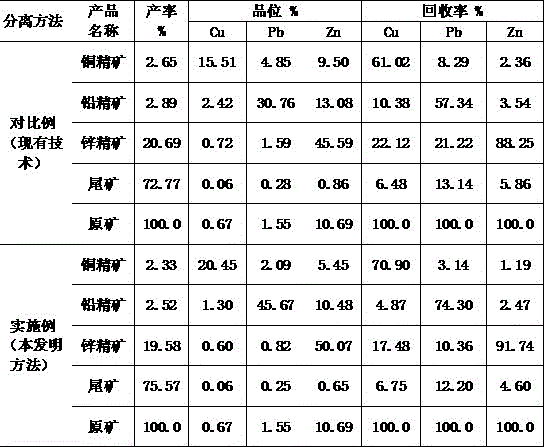

[0026] The process method of the prior art (comparative example): firstly, the crushed raw ore and water are added to a ball mill at a ratio of 1:1 for grinding, until the grinding fineness of the material discharged from the ball mill reaches -0.074mm, accounting for 90-95%. Add inhibitor lime 2500g / t+zinc sulfate 1000g / t, collector butyl xanthate 80g / t, foaming agent terpineol oil 10g / t for copper-lead mixed roughing; Grind to a fineness of -0.045mm90~95%, regrind the product for four times to obtain copper-lead mixed concentrate, add activated carbon 200g / t, inhibitor sodium sulfite 500+ sodium silicate 250g / t+CMC50g / t. Collector Z-2006g / t for copper and lead separation, copper and lead separation after a rough separation twice beneficiation and two sweeps to obtain copper concentrate and lead concentrate; copper and lead mixed tailings add inhibitor lime 1000g / t, activator copper sulfate 300g / t, butyl xanthate 100g / t, foaming agent terpineol oil 10g / t for separation of zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com