Production process for concentrating water coal slurry by gasification in coal chemical industry and used device

A gasification coal-water slurry and production process technology, applied in the petroleum industry, liquid carbon-containing fuel, grain processing, etc., can solve the problems of small production capacity, high failure rate, high energy consumption, etc., and achieve high production capacity and low failure rate , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

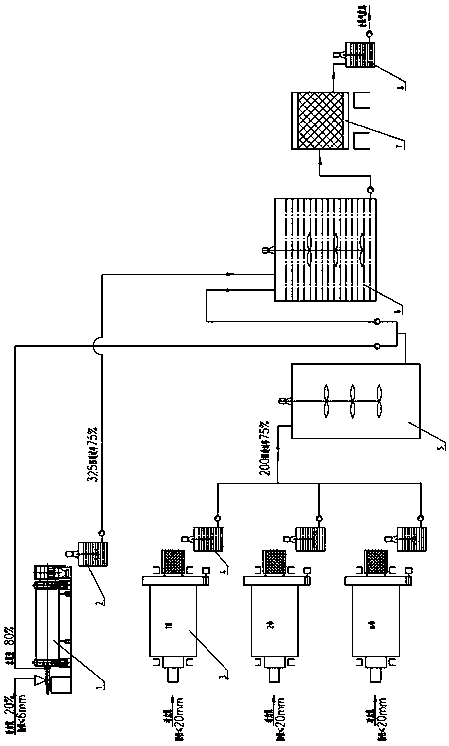

[0015] Such as figure 1 As shown, a coal chemical gasification coal-water slurry thickening production process includes the following steps:

[0016] (1) Put thermal coal with a particle size of ≤20mm into multiple rod mills for grinding to obtain a 200-mesh crude coal-water slurry with a passing rate of 75%, and then enter the buffer tank of the rod mill after preliminary screening, and be pumped to the slurry tank;

[0017] (2) Extract 10% to 20% of the crude coal water slurry entering the slurry tank and send it to a ball mill for grinding together with thermal coal with a particle size ≤ 6mm. Among them, the crude coal water slurry accounts for 80% to 90% , steam coal with a particle size of ≤6mm accounts for 10% to 20%, and a fine coal water slurry with a passing rate of 75% at 325 mesh is obtained. The fine coal water slurry in the agitator accounts for 10% to 20% of the total slurry in the mixing agitator; the remaining coarse coal water slurry after entering the slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com