Steam coal separation method

A thermal coal and separation technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as doping clean coal, improve recovery rate, improve separation accuracy and hourly processing capacity, improve The effect of sorting conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

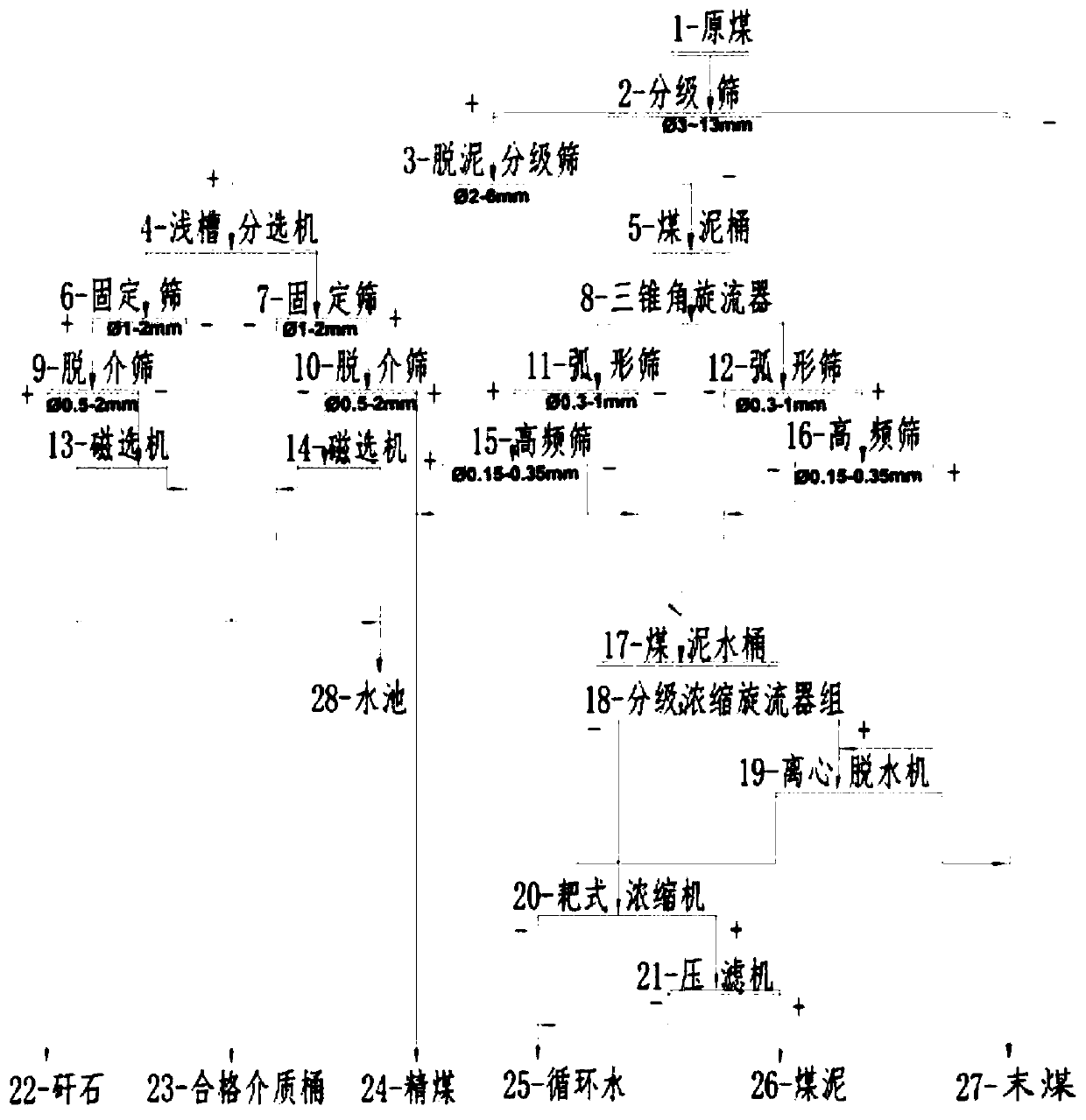

[0048] The raw lignite coal is fed through a Φ3mm grading sieve (2) at a feed rate of 1000 tons / hour. The product under the sieve is fine coal (27). The upper part of the sieve enters the Φ2mm desliming and grading sieve (3), Φ2mm desliming and grading sieve ( 3) The sieve enters the heavy medium shallow slot separator (4), and the coarse and clean coal after separation by the heavy medium shallow slot separator (4) passes through the Φ1mm fixed screen (7) and the Φ0.5mm de-medium screen (10) 600 tons / hour of clean coal (24) will be produced after the dehydration and de-intermediation. The water under the Φ0.5mm de-intermediate sieve (10) will enter the magnetic separator (14) de-intermediate; after the heavy-medium shallow groove separator (4) is separated After the coarse gangue of Φ1mm fixed sieve (6) and Φ0.5mm de-intermediation sieve (9) are dehydrated and de-intermediate, gangue (22) is produced, and the water under the Φ0.5mm de-intermediation sieve (9) enters the magneti...

Embodiment 2

[0051] The raw coal of long flame coal is fed through a Φ13mm grading sieve (2) at a feed rate of 1000 tons / hour (1), the product under the sieve is fine coal (27), and the sieve enters the Φ6mm desliming and grading sieve (3), Φ6mm desliming and grading The sieve (3) enters the heavy-medium shallow groove separator (4), and the coarse and clean coal after the heavy-medium shallow groove separator (4) passes through a Φ2mm fixed sieve (7) and a Φ2mm de-medium sieve (10) 400 tons / hour of clean coal (24) will be produced after the dehydration and de-intermediation. The water under the Φ2mm de-intermediate sieve (10) will enter the magnetic separator (14) de-intermediate; Gangue is dehydrated and de-intermediated by Φ2mm fixed sieve (6) and Φ2mm de-intermediation sieve (9) to produce gangue (22), Φ2mm de-intermediation sieve (9), sieve water enters the magnetic separator (13) de-intermediation, Φ2mm de-intermediation sieve (10) The water under the sieve enters the magnetic separat...

Embodiment 3

[0054] Feed the raw coal of lean coal at a feed rate of 1000 tons / hour (1) through a Φ5mm grading sieve (2), the product under the sieve is fine coal (27), and above the sieve enters Φ4mm desliming and grading sieve (3), Φ3mm desliming and grading sieve (3) On the screen, enter the heavy medium shallow slot separator (4), and the coarse and clean coal after the heavy medium shallow slot separator (4) passes through the Φ1mm fixed screen (7) and the Φ1mm de-medium screen (10). After dehydration and de-intermediation, 550 tons / hour of clean coal (24) will be produced, and the water under the Φ1mm de-intermediate sieve (10) will enter the magnetic separator (14) de-intermediate; the coarse gangue after the separation by the heavy-medium shallow trough separator (4) Gangue (22) is produced after dehydration and de-intermediation of Φ1mm fixed sieve (6) and Φ1mm de-intermediation sieve (9). The water under the Φ1mm de-intermediation sieve (9) enters the magnetic separator (13) for de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com