A Dry Sorting and Recovery Process for Valuable Components in Waste Circuit Boards

A waste circuit board and dry process technology, which is applied in the field of dry separation and recovery of valuable components in waste circuit boards, can solve the problems of narrow feed particle size range and low recovery efficiency, and achieve efficient separation and recovery. , Improve quality and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

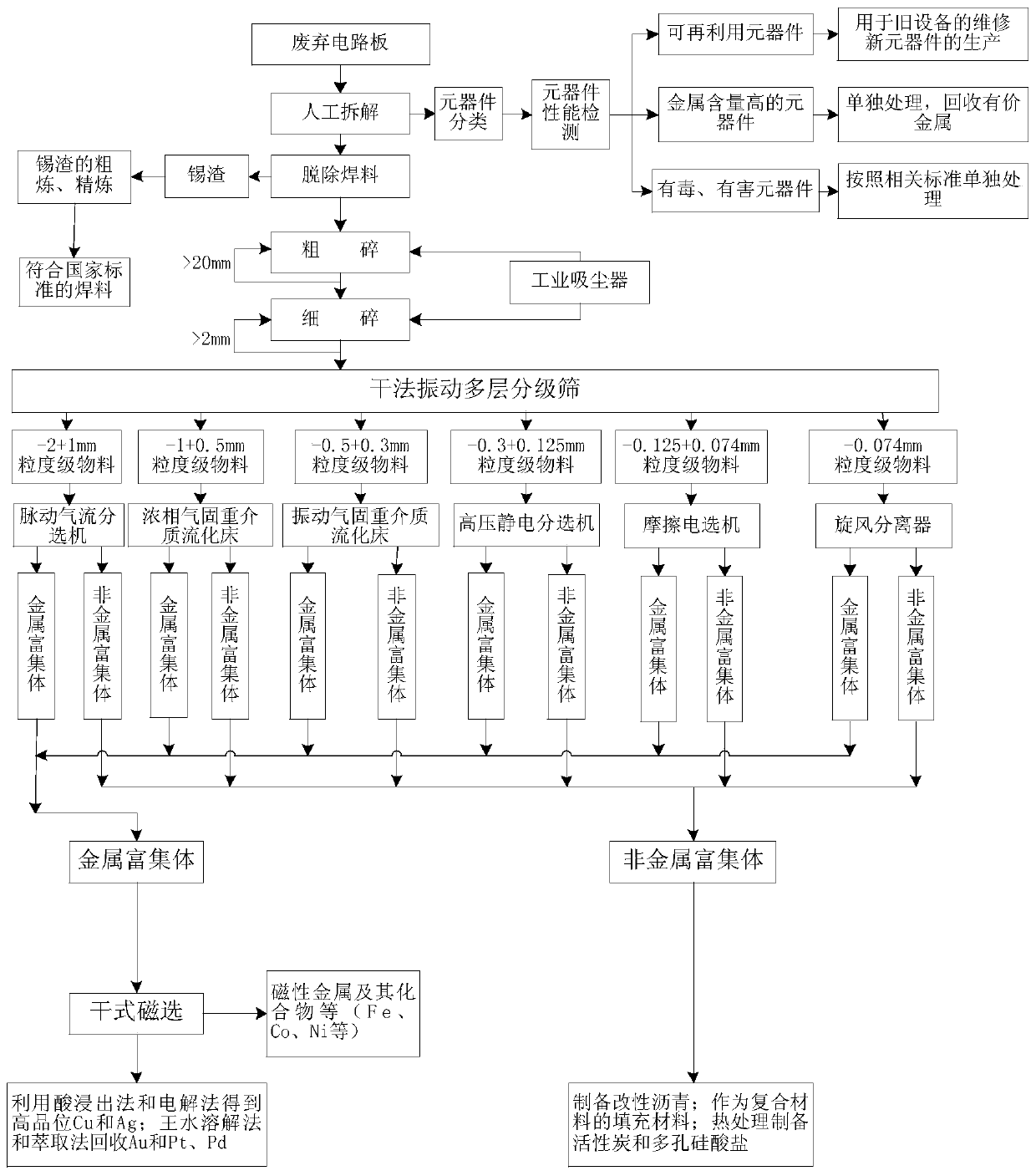

[0054] The present invention is a dry sorting and recovery process for valuable components in waste circuit boards, the specific process is as follows figure 1 As shown, the dry separation and recovery process of valuable components in the waste circuit boards of computers in this embodiment is as follows:

[0055] Step 1. Disassemble the discarded circuit board of the computer to obtain a 5kg bare board of the discarded circuit board of the computer after dismantling, and the components obtained by dismantling the discarded circuit board of the computer go through the component classification and performance testing process to obtain There are three types of reusable components, components with high metal content and toxic and harmful components; in this embodiment, the discarded circuit boards of the computer are disassembled to obtain the components on the discarded circuit boards as resistors, capacitors, inductors, diodes, and triodes , relays, integrated circuits, etc., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com