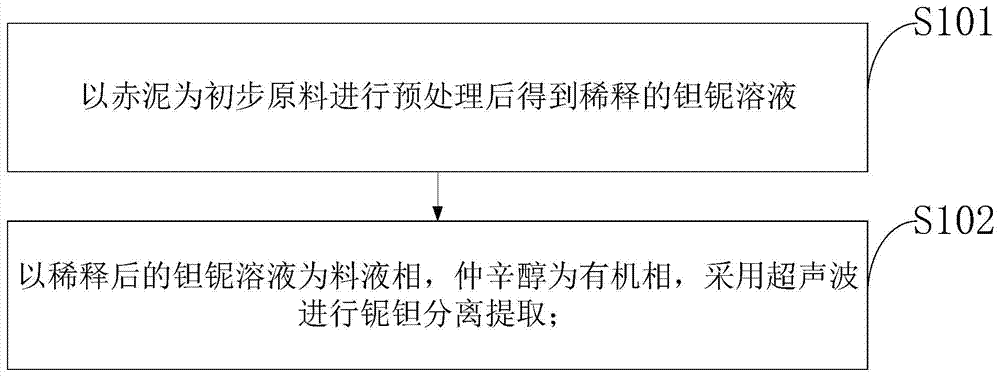

A method for separating tantalum and niobium from red mud by using ultrasonic waves

An ultrasonic and red mud technology, applied in the direction of improving process efficiency, can solve the problems of many processing processes, high environmental impact pressure, and difficult waste treatment, and achieve simple extraction process, improve quality, and be conducive to environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

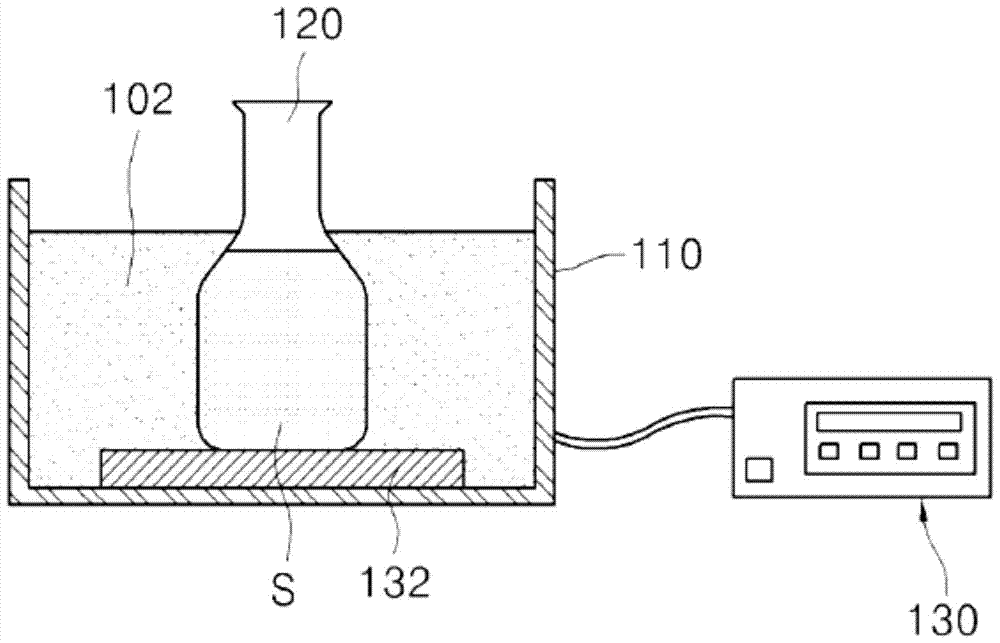

Embodiment 1

[0060] Put 30g of red mud and 900ml of distilled water in a 2L triangular flask inserted into the thermostat, and mix 225ml of hydrochloric acid (HCl) and 75ml of nitric acid (HNO3), and heat the thermostat to 75°C , while applying ultrasonic waves at a frequency of 36.7kHz and an output power of 280W, it reacted for 6 hours. Afterwards, the reactant is filtered, and the red mud residue and the extraction filtrate are separated and recovered respectively. Thereafter, the recovered red mud residue was washed with distilled water, and dried at 60° C. for 12 hours. At this time, the extraction filtrate, which is a solution containing extracted tantalum and niobium, was analyzed using ICP (PerkinElmer, OPTIMA 2100DV).

Embodiment 2

[0062] An experiment was carried out in the same manner as in Example 1, except that 300 ml of hydrochloric acid (HCl, 35%) was used instead of the mixed acid of hydrochloric acid and nitric acid and mixed as an acidic solution.

Embodiment 3

[0064] Experiments were carried out in the same manner as in Example 1, except that 300 ml of nitric acid (HNO3, 65%) was used as an acidic solution instead of the mixed acid of hydrochloric acid and nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com