Method for determining best setting value of chain furnace control system

A technology of control system and determination method, applied in control system, combustion equipment, lighting and heating equipment, etc., can solve problems such as failure to realize economical, energy-saving, safe and reliable operation of chain furnaces, detection of operating parameters of chain furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below using the drawings and examples.

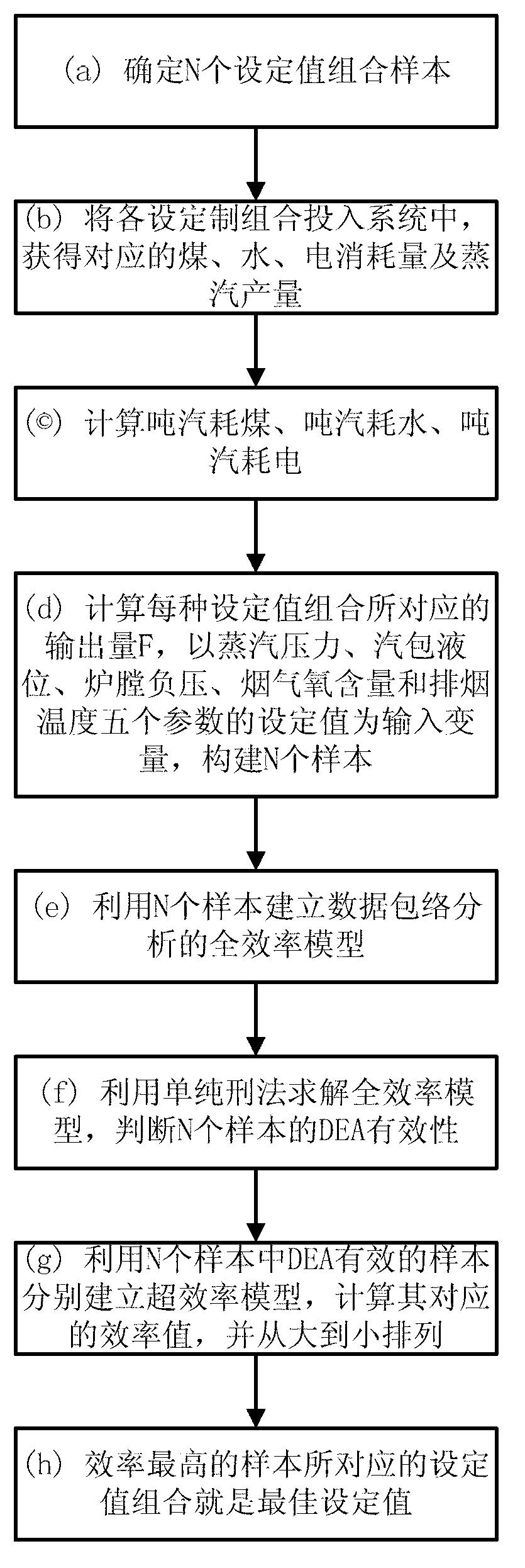

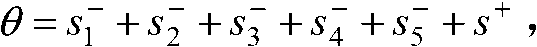

[0057] A method for determining the optimal setting value of a chain furnace control system, comprising the following steps:

[0058] (a) Based on experience, determine N feasible set value combinations of the five parameters of chain furnace steam pressure, steam drum liquid level, furnace negative pressure, flue gas oxygen content and exhaust gas temperature.

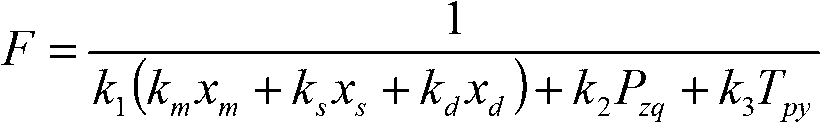

[0059] (b) Put each set value combination into the chain furnace control system in turn, and use each monitoring point to obtain the coal consumption quantity M corresponding to each combination m , water consumption M s , Electricity consumption quantity M d and the amount of steam generated M zq .

[0060] List of parameters to be collected specifically in the present invention

[0061] serial number

parameter name

unit

1

Steam pressure P zq

KPa

2

Drum liquid level h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com