Multi-stage screening and fine coal removal type preparation method of sized raw coal of power coal

A thermal coal and screening technology, applied in the fields of magnetic separation, chemical instruments and methods, sieves, etc., can solve the problems of low product quality, low washing rate, etc., and achieve low operating costs, significant economic benefits, and high processing capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

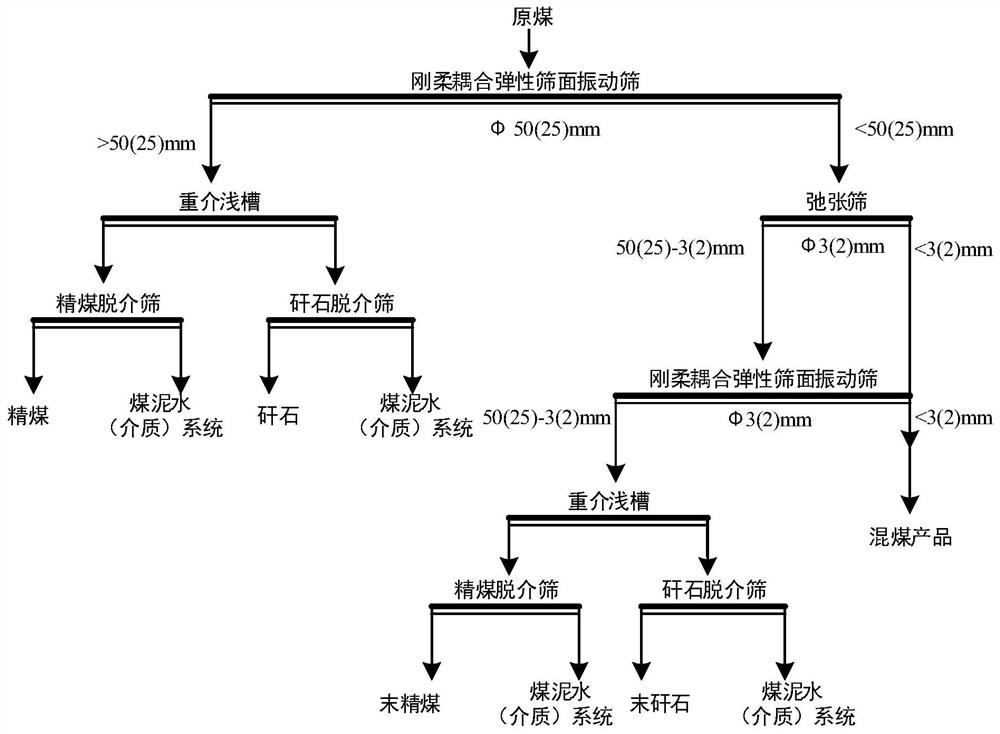

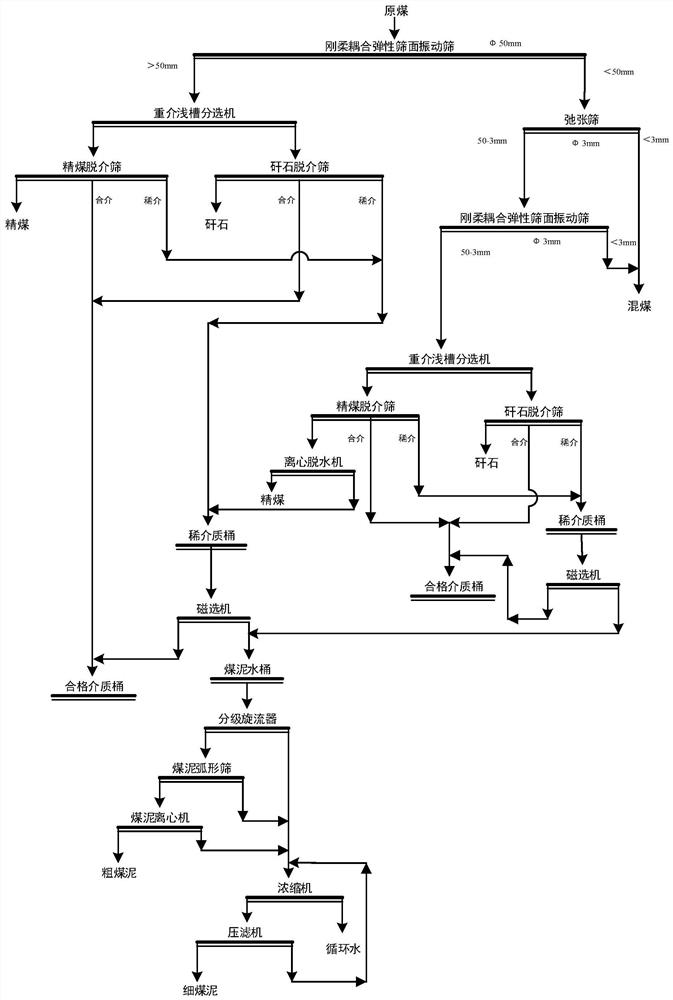

[0033] like figure 2 As shown, the application of the method of the present invention is introduced below through a specific production example. This case is only for the convenience of understanding the solution of the present invention, and should not be interpreted as that the present invention is limited thereto:

[0034] A classification and selection method for steam coal multi-stage screening and powder removal, comprising the following steps:

[0035] Step A1: Raw coal enters the first rigid-flexible coupled sieve surface elastic vibrating screen for dry classification, the sieve size of which is 50mm, and the material > 50mm on the sieve enters the dense medium shallow groove separator for separation;

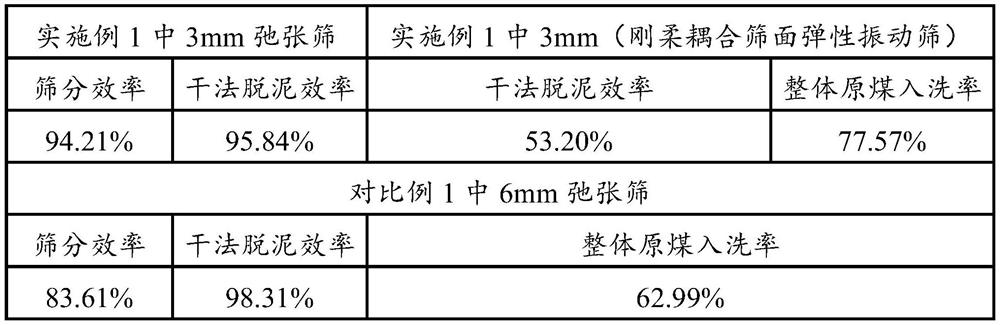

[0036] Step B1: The material <50mm under the first rigid-flexible coupling sieve surface elastic vibrating sieve enters the relaxation sieve for dry classification. The sieve surface vibrating screen is used for dry depowdering. The sieve hole size is 3mm. After depo...

Embodiment 2

[0043] Steps E2 to G2 of this embodiment are the same as Steps E1-G1 of Embodiment 1, except that in steps A2 to D2, the mesh size of the relaxation screen and the elastic vibrating screen with the second rigid-flexible coupling screen surface is 2 mm;

[0044] Specifically:

[0045] Step A2: The raw coal enters the first rigid-flexible coupled screen surface elastic vibrating screen for dry classification, the screen hole size is 50mm, and the material > 50mm on the screen enters the dense medium shallow groove separator for classification;

[0046] Step B2: The material <50mm under the elastic vibrating screen with rigid-flexible coupling screen surface enters the relaxation sieve for dry classification. The vibrating sieve is used for dry depowdering, the sieve hole size is 2mm, the 50-2mm material on the sieve after depowdering enters the dense medium shallow groove sorter for sorting, the material under the relaxation sieve and the 2mm rigid-flexible coupling elastic siev...

Embodiment 3

[0050] Steps E3 to G3 of this embodiment are the same as steps E1-G1 of Embodiment 1, except that in steps A3 to D3, the mesh size of the first rigid-flexible coupling screen elastic vibrating screen is 25mm;

[0051] Specifically:

[0052] Step A3: The raw coal enters the elastic vibrating screen with a rigid-flexible coupling screen surface for dry classification. The screen hole size is 25mm, and the material > 25mm on the screen enters the dense medium shallow groove separator for classification;

[0053] Step B3: The material <25mm under the elastic vibrating screen with rigid-flexible coupling screen surface enters the relaxation sieve for dry classification. The sieve size is 3mm. Carry out dry de-powdering, the sieve size is 3mm, the 25-3mm material on the sieve after de-powdering enters the dense medium shallow groove sorter for sorting, the material under the relaxation sieve and the 3mm rigid-flexible coupling elastic sieve surface vibrate The material under the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com