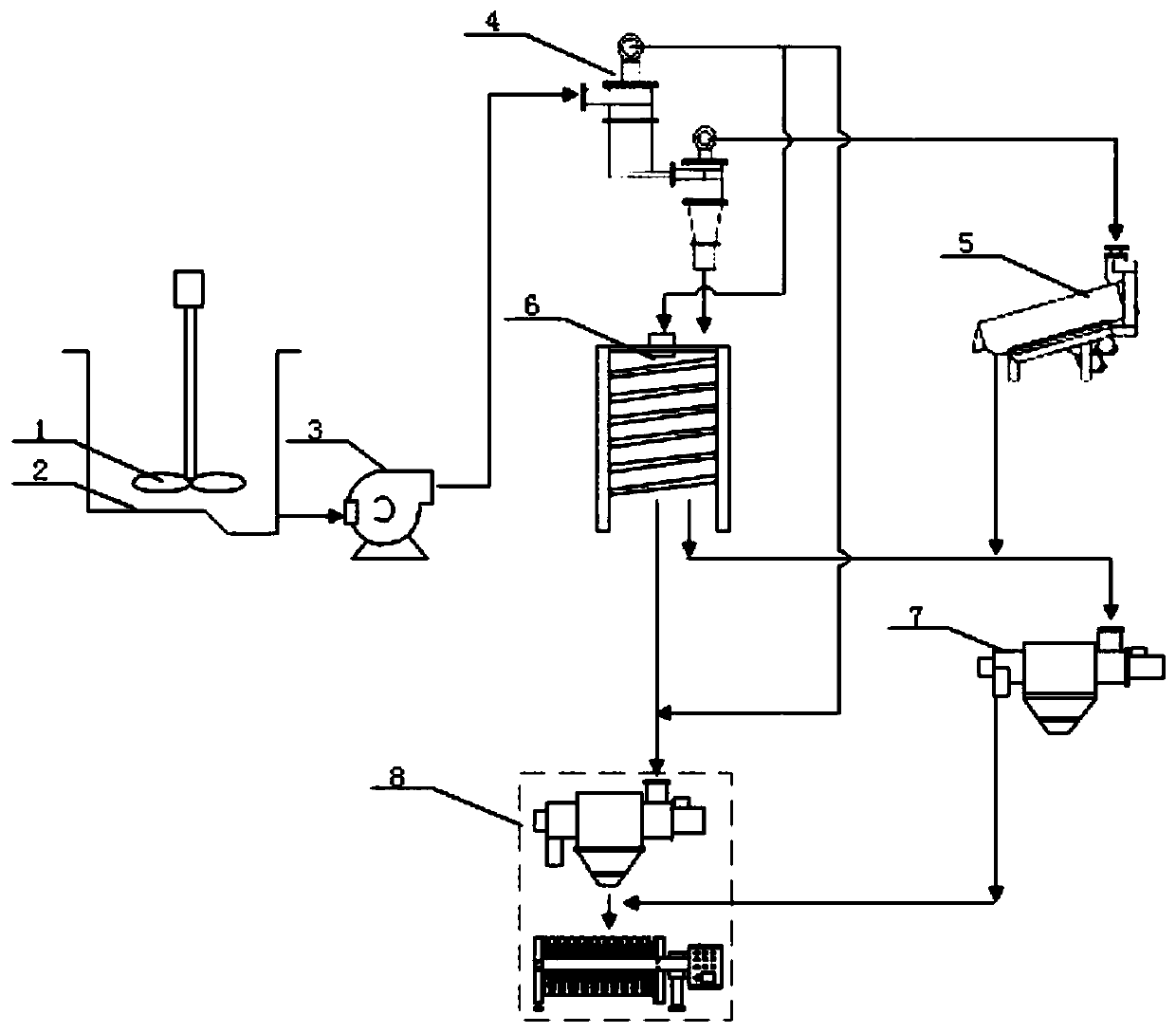

Device and process for recovering jigging overflow coal slime to separate ultra-clean coal through physical cyclone flow

A sorting device and overflow technology, applied in the direction of solid separation, etc., can solve the problems of product pollution, serious dielectric consumption and high cost, and achieve the effects of novel and unique ideas, low operating costs, and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

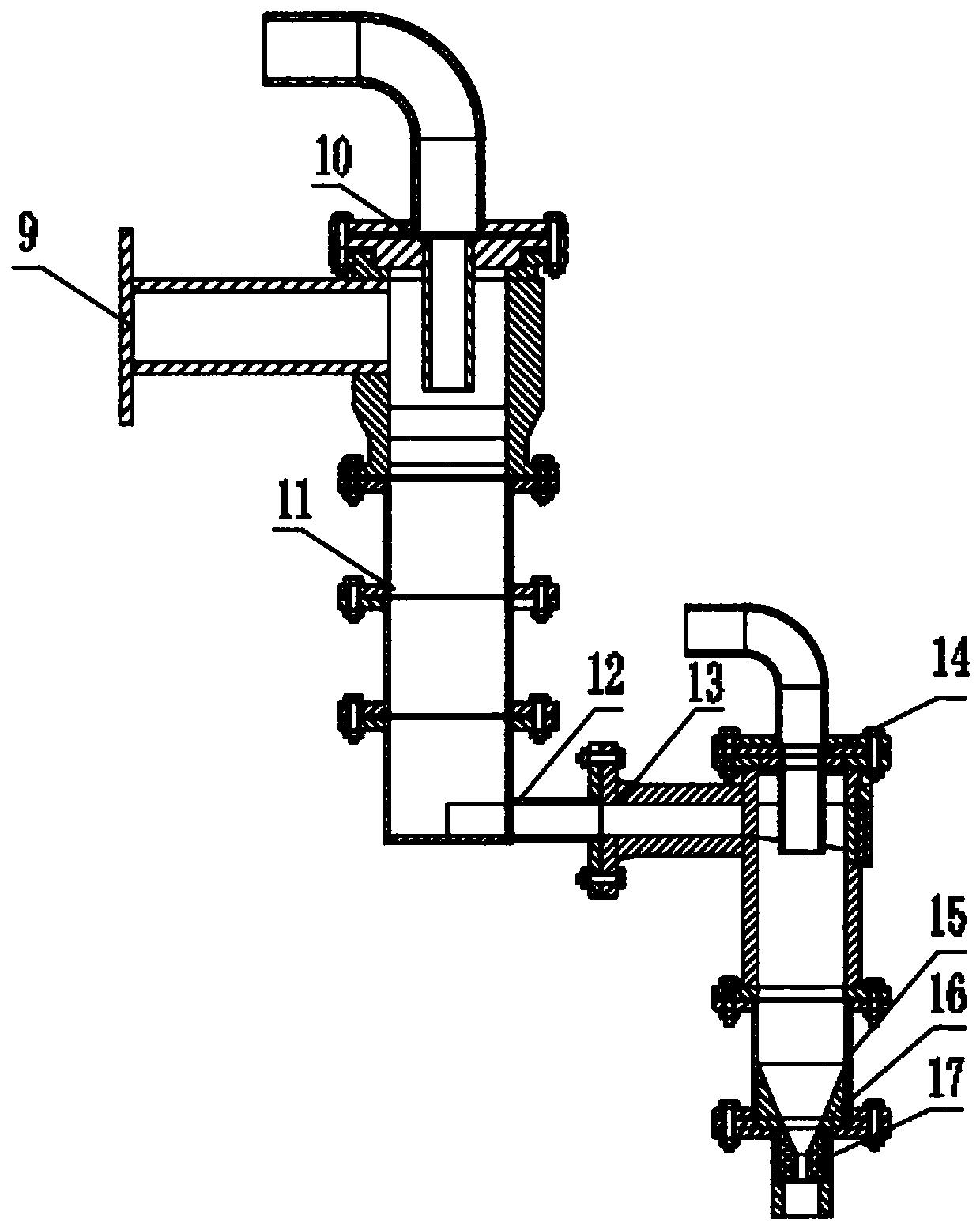

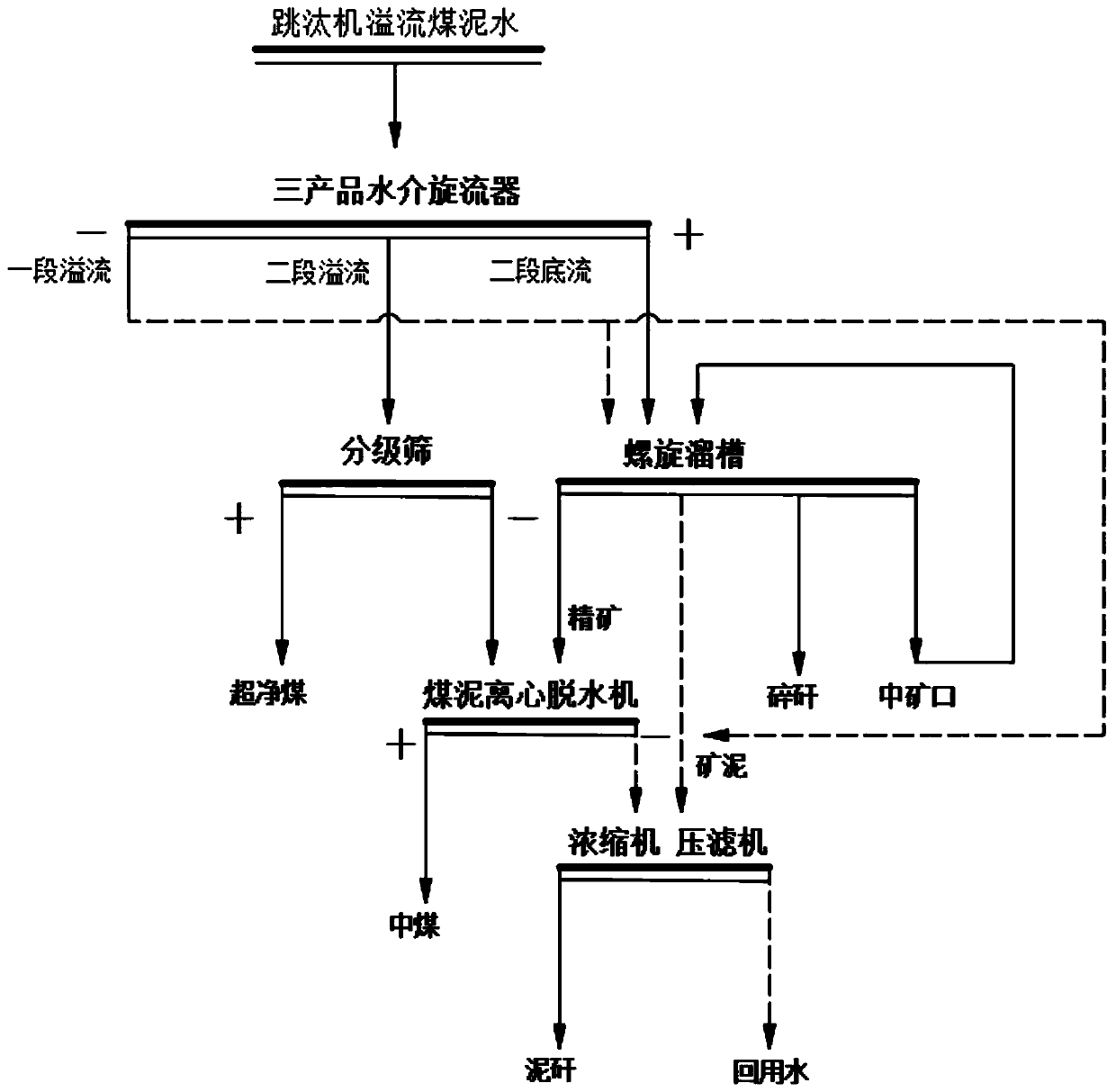

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Taking the overflow coal slime of a jig in a coal preparation plant in Ordos, Inner Mongolia as an example, the properties of the coal samples are shown in Table 1 and Table 2.

[0041] Table 1 Coal sample particle size composition

[0042]

[0043] It can be seen from Table 1 that the overall ash content is 31.35%, and the ash content mainly occurs in the finer and coarser grain grades. The ash content is above 40%, but the yield is low, and the ash content in the -0.55mm to +0.125mm particle size grade is relatively low, and this part can be used for clean coal recovery.

[0044] Table 2 Density composition of coal samples

[0045]

[0046] As can be seen from Table 2, at -1.3g / cm 3 At the density level, the ash content is 2.80%, and the yield rate is 25.29%, indicating that this part can be recovered as ultra-clean coal, 1.3-1.5g / cm 3 At the density level, the ash content is less than 10%, and the yield is 29.40%. This part can be recovered as cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com