Separation technique for difficult-to-separate steam coal

A thermal coal separation technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problem of low processing cost per ton of coal, increase washing cost, intensify contact and convection between materials and dense medium suspension, etc. problems, to achieve the effect of solving the product recovery rate, minimizing the cost of sorting, and reducing the amount of secondary slime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

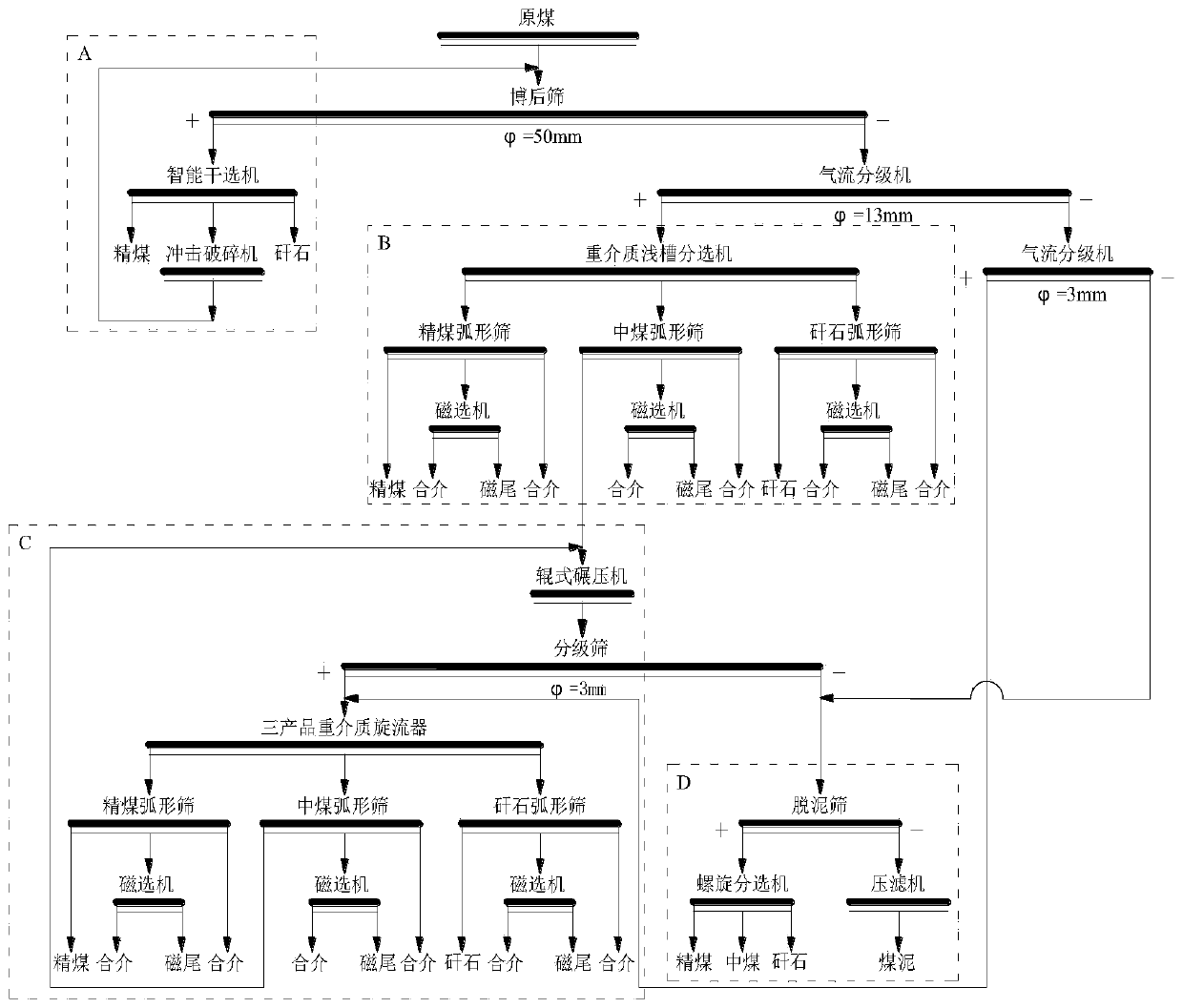

[0033] The refractory thermal coal separation process of the present invention includes the use of post-doctoral screens, intelligent dry separators, impact crushers, airflow classifiers, dense medium shallow tank separators, de-mediation screens, magnetic separators, and roller crushers. , dense medium cyclone, desilting screen, screw separator and filter press. The specific implementation steps are as follows:

[0034] (1) The selected raw coal is pre-screened by post-doctoral sieve (screening size is 50mm), and the sieved material (+50mm) after screening is sorted into the intelligent dry separator to obtain clean coal, medium coal, and gangue. products, wherein the medium coal products are all fed into the impact crushing stage for crushing, and returned to the post-graduate sieve (the sieving size is 50mm) for sieving and re-election;

[0035] (2) The pre-screened undersize (-50mm) is fed into the air classifier (classification particle size is 13mm) for classification, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com