Non-quantitative washing method for low-quality coal slime

A low-quality coal and slime technology, applied in solid separation, recycling technology, waste treatment, etc., can solve the problems of increasing environmental protection pressure, increasing washing costs, commercial coal cannot reach the factory volume, etc., and achieve water resource utilization saving The effect of optimizing, optimizing the effective allocation of resources, and maximizing commercial coal output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

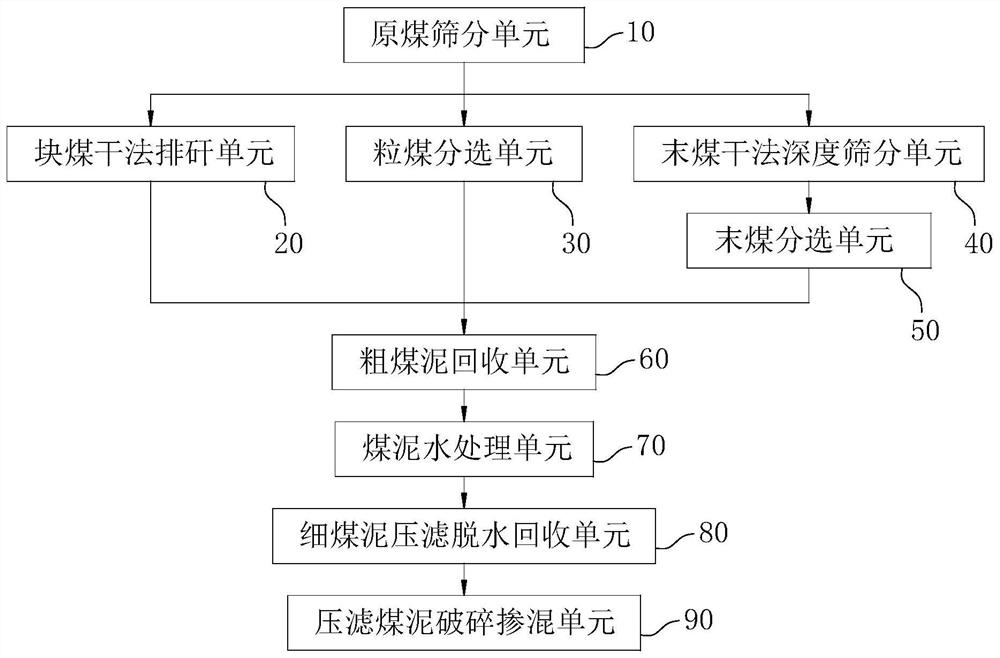

[0051] For ease of understanding, combined here Figure 1-9 , the concrete structure and working mode of the present invention are further described as follows:

[0052] Low-quality coal slime non-quantitative washing method of the present invention, such as figure 1 The shown sequence is divided into the following nine units: raw coal screening unit 10, lump coal dry gangue discharge unit 20, granular coal separation unit 30, fine coal dry deep screening unit 40, fine coal separation unit 50 , a coarse coal slime recovery unit 60 , a coal slime water treatment unit 70 , a fine coal slime pressure filtration dehydration recovery unit 80 and a pressure filtration coal slime crushing and mixing unit 90 .

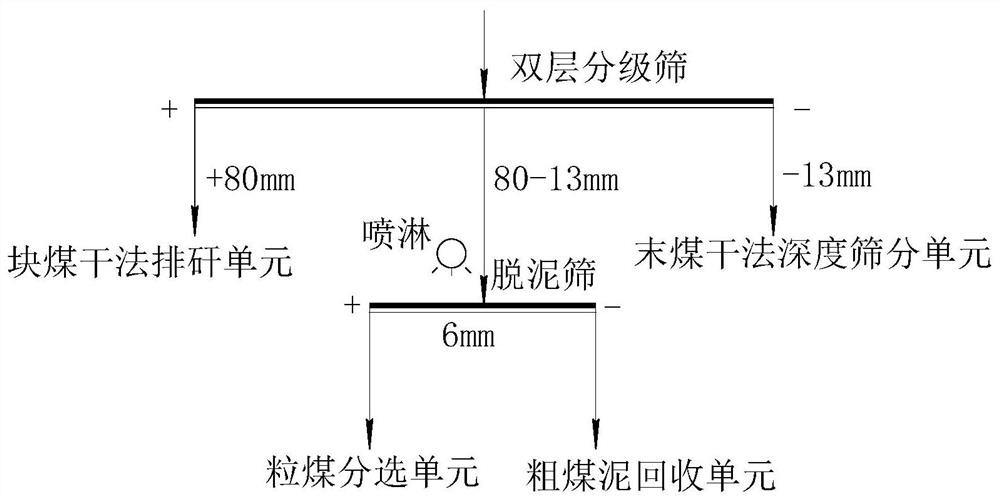

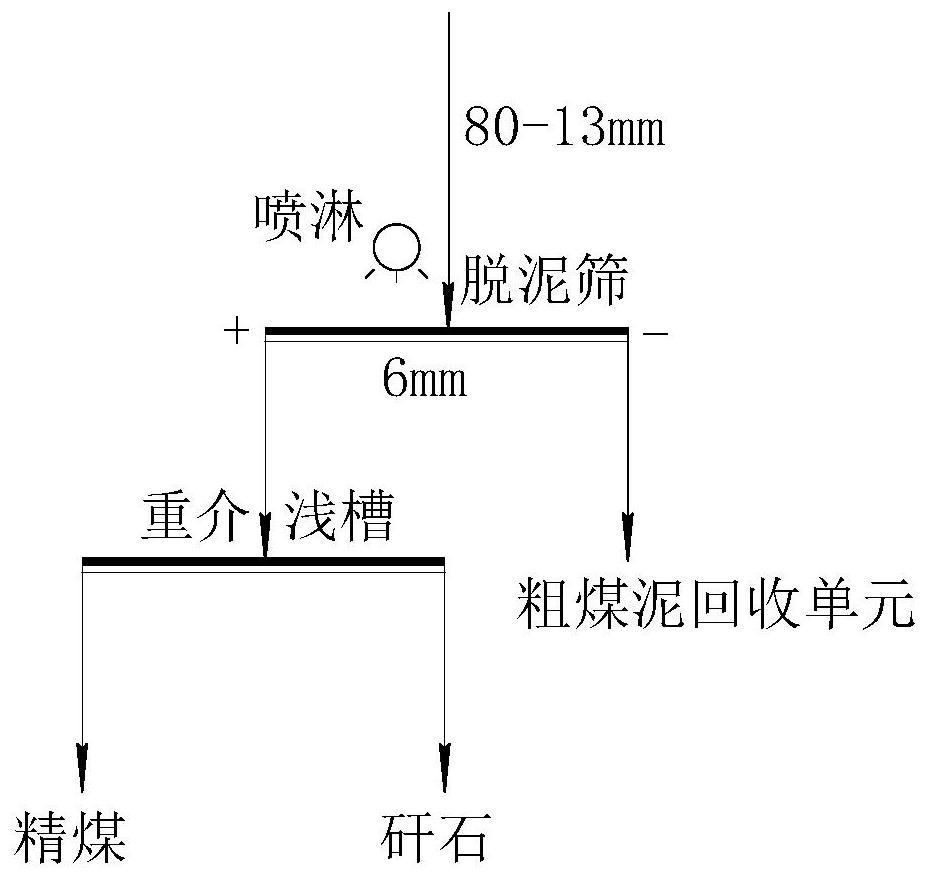

[0053] The main equipment of the raw coal screening unit 10 is a double-layer grading screen, the upper sieve hole is 80mm, and the lower sieve hole is 13mm. The raw coal screening unit 10 divides the raw coal into +80mm granular coal, 80-13mm granular coal and fine-grained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com