Efficient airflow classification fine-coal remover for power coal before selecting

A technology of airflow classification and steam coal, which is applied in the direction of separating solids from solids by airflow, solid separation, chemical instruments and methods, etc., can solve the problems of waste of resources and environment, poor adaptability of coal types, high production costs, etc., to achieve Uniform material distribution, increase production capacity, and solve the effect of sieve blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

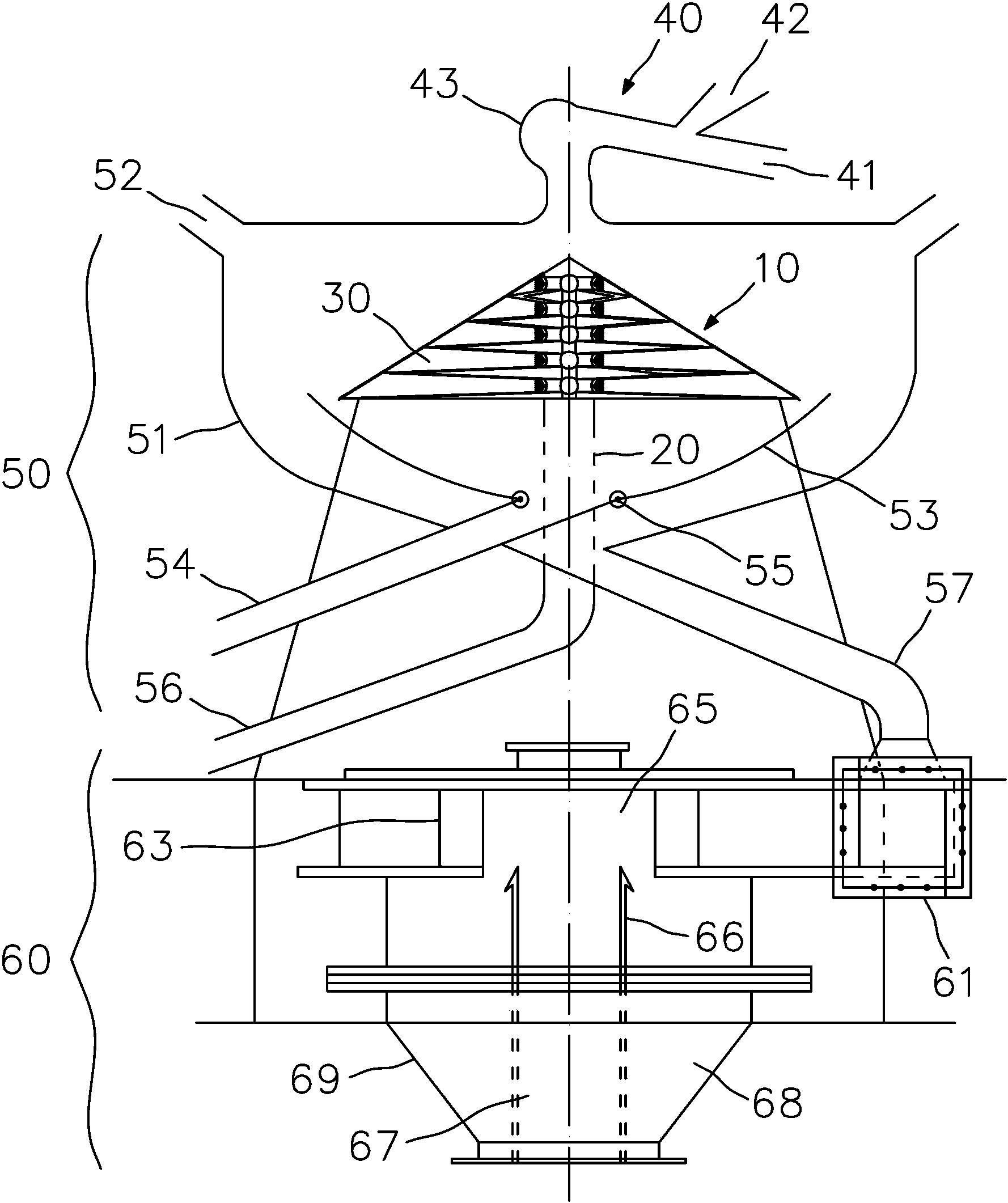

[0049] Such as figure 1 As shown, a high-efficiency airflow classification depulverizer before thermal coal selection includes the following components:

[0050] The material dispersing area 40 is used to make the materials disperse each other after colliding under the impingement of the airflow. At this time, it is the primary dispersing of the materials, and the dispersed materials enter the primary grading area;

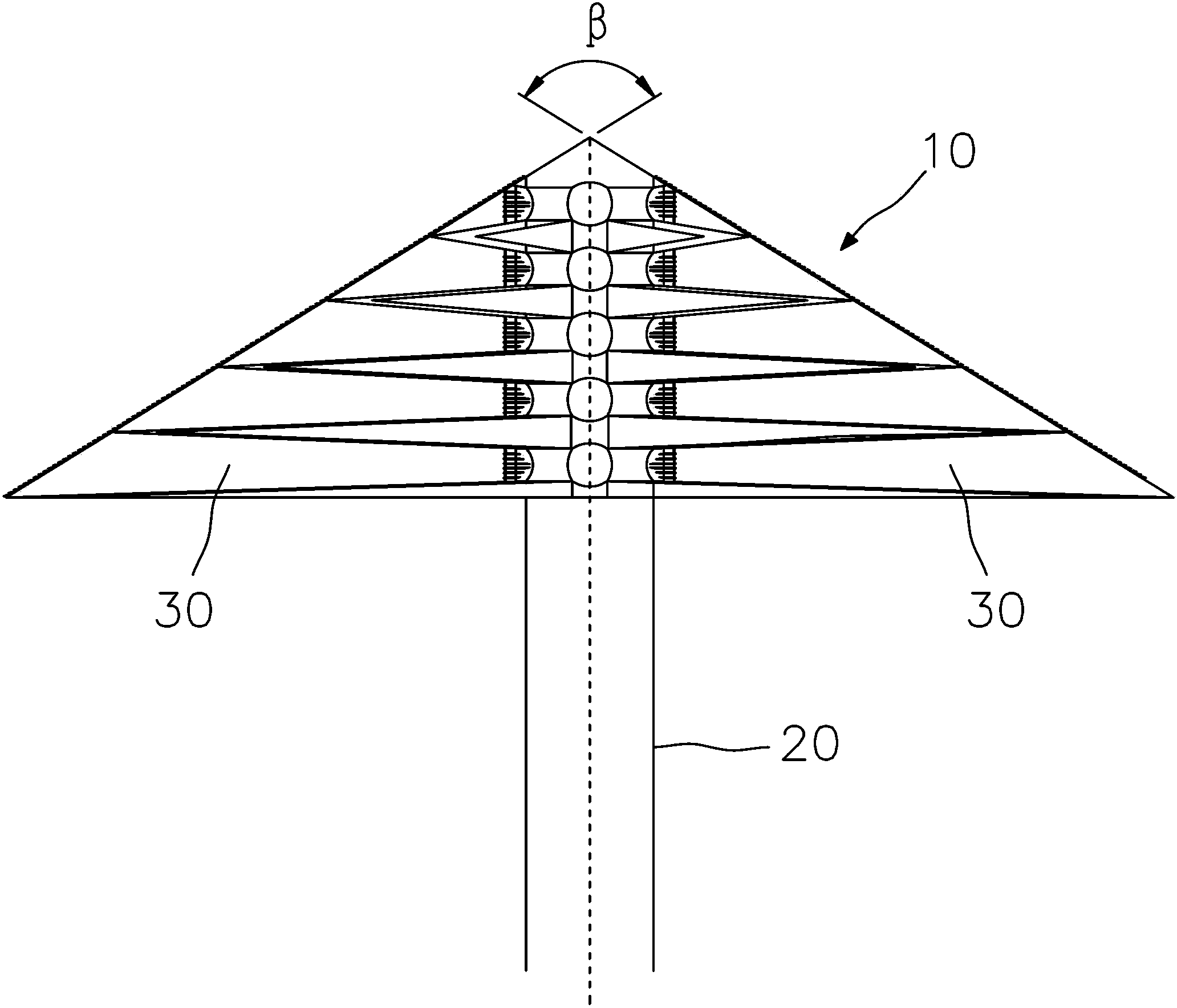

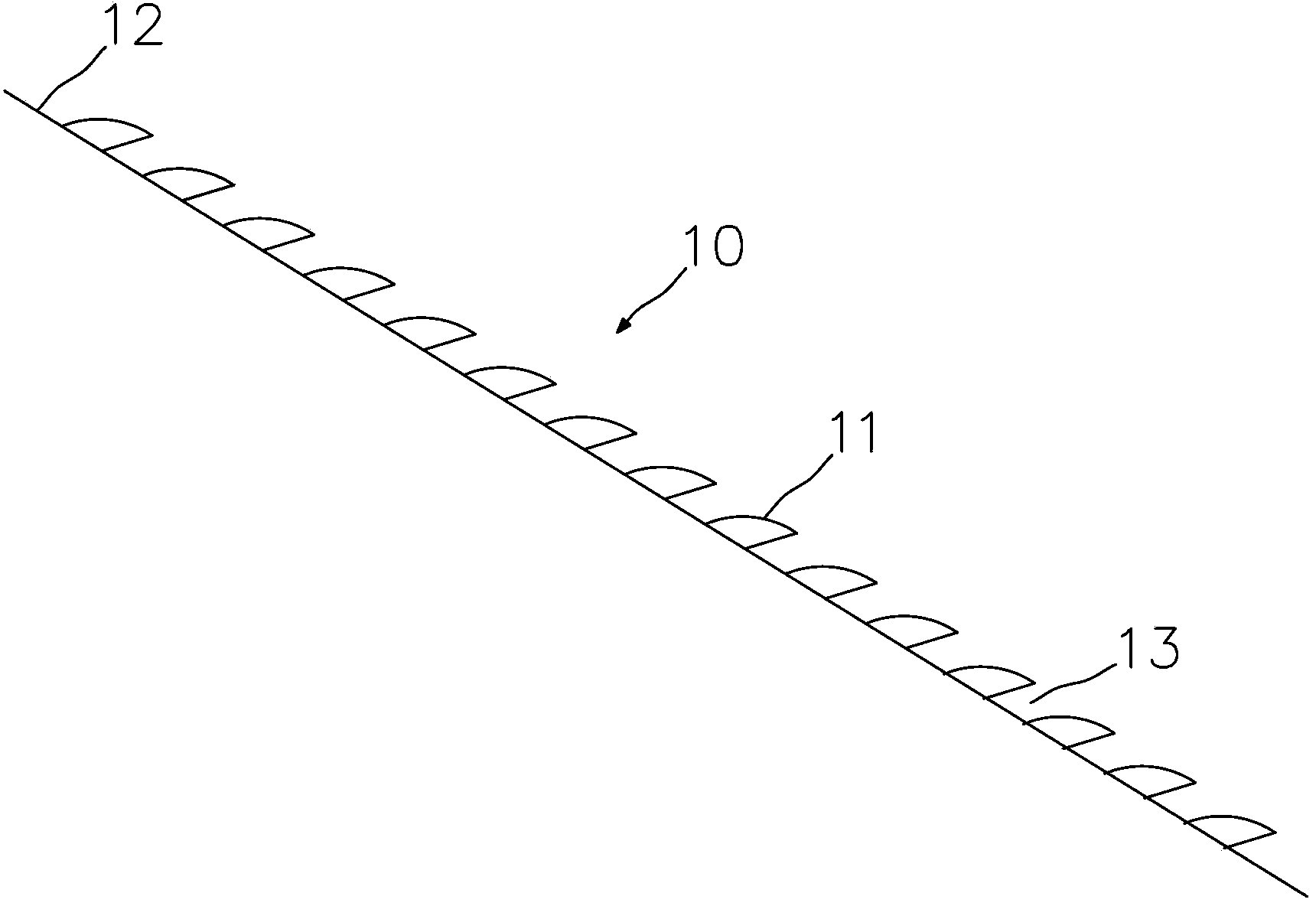

[0051] The primary classification area 50, the primary classification area includes a silo 51, the silo 51 is provided with an air outlet 52, and the silo 51 is equipped with a 360-degree full-circle air distribution mechanism, and the materials after primary dispersion are passed through a 360-degree full-circle The secondary dispersion is obtained after colliding and sliding to the air distribution mechanism and the impact of the airflow. The material after the secondary dispersion is divided into primary fine particle material and primary coarse particle materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com