Apparatus and method for wash separating coal by jump separation

A gangue-discharging jig and jig technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of increasing the basic links of the whole system, complicated equipment manufacturing, and large power consumption, and achieve the goal of manufacturing Simplicity, reduced washing cost, and total cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

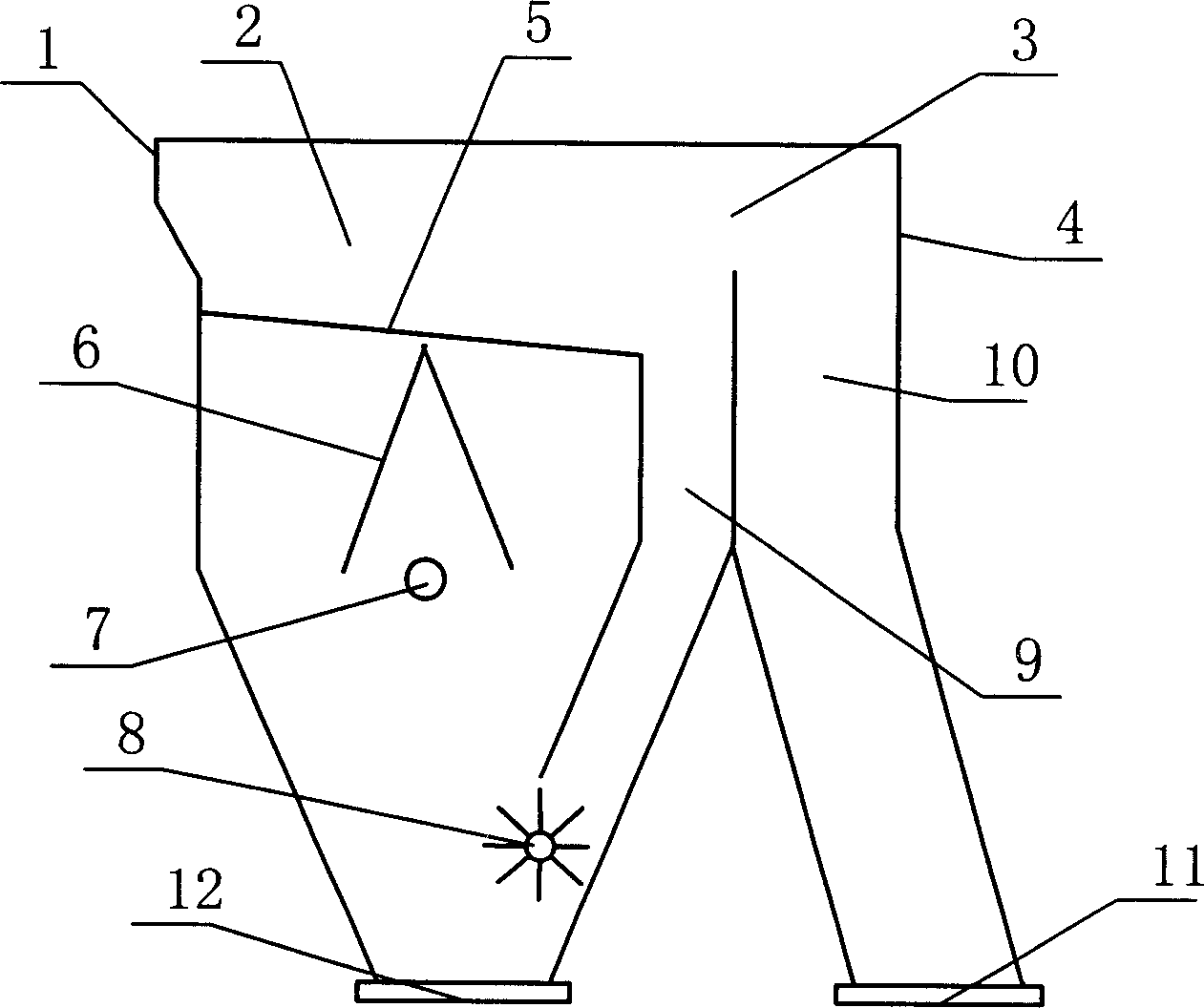

[0044] Example 1, figure 1 Among them, an air chamber gangue-discharging jig, which includes an existing single-stage jig body 1 and a discharge channel 4. The inclination angle of the sieve plate 5 in the single-stage jig machine body 1 is larger than conventional ones. The discharge channel 4 is a closed device with an upper opening, and is composed of a feed port 3, a connecting channel 10 and a clean coal discharge port 11. The feed port 3 of the discharge channel 4 is connected to the existing single-stage jigging The overflow port of the machine body 1 is adapted, and the periphery is sealed and connected, and it can also be made as a common port of the same wall. The uppermost part of the discharge channel 4 is in the shape of a cuboid, and the lower part is a cylindrical connecting channel 10 . The connecting channel 10 can be straight, can also be made into various bends, can also be made into oblique or other forms, and the section can be rectangular, circular, or ...

Embodiment 2

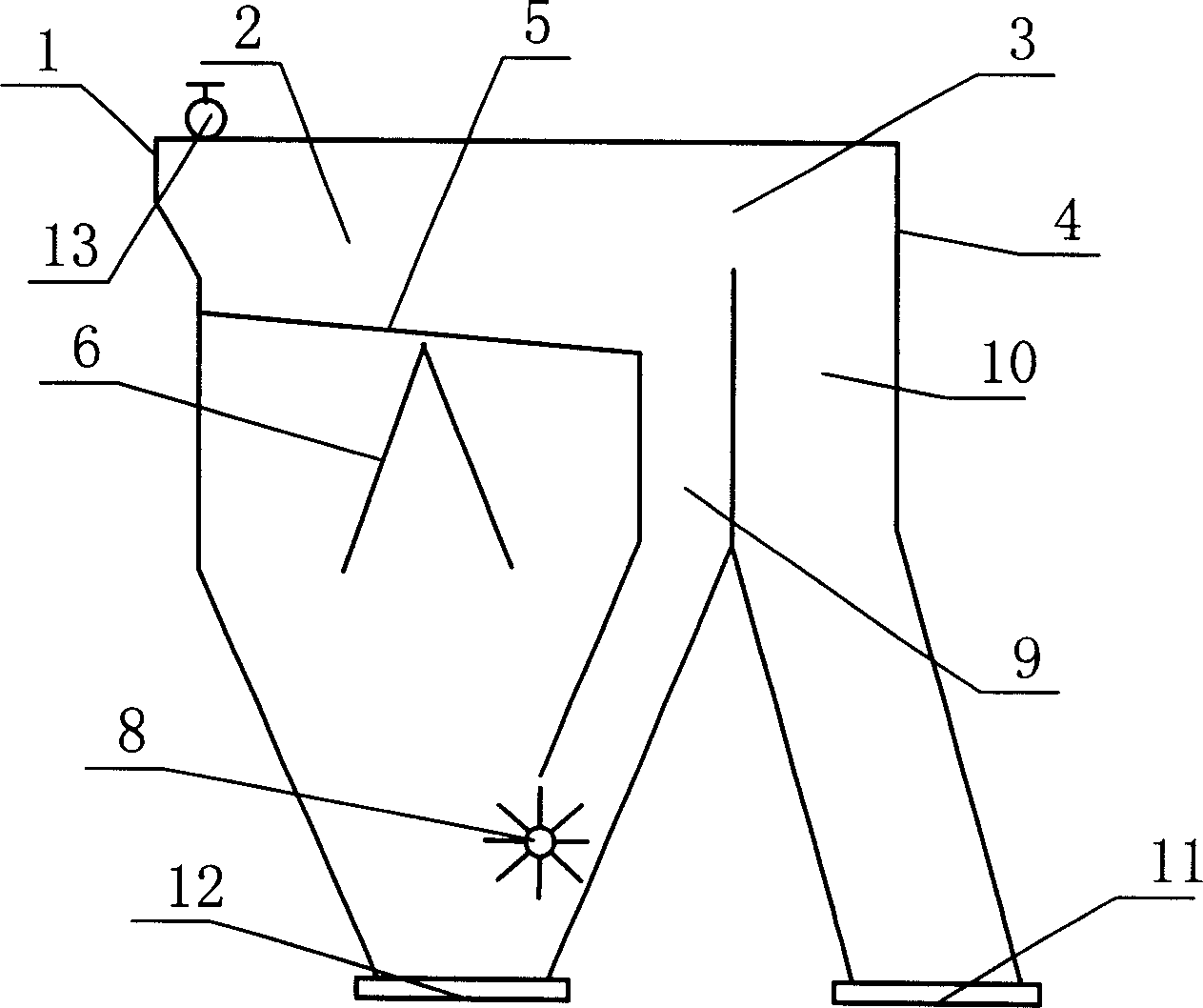

[0048] Example 2, in figure 2 Among them, another air chamber gangue-discharging jig, the shape, structure, materials used, and functions of the single-stage jig body 1 are as described in Example 1. The main shape, structure, materials used, effect, etc. of the discharge channel 4 are also as described in Embodiment 1, and the difference is that figure 1 The top water device 7 of the single-stage jig body 1 described in the above is canceled, and a water replenishment device 13 with an adjustable water flow rate is installed on the upper part of the single-stage jig body 1 near the middle and rear. The installation direction of replenishment device 13 is advisable with easy operation, can be on the left side of single stage jig machine body 1 or right side.

[0049]When this embodiment is working, the working steps, methods, principles, etc. are as described in Embodiment 1, the difference is that a certain amount of water is added to the single-stage jig body 1 through the...

Embodiment 3

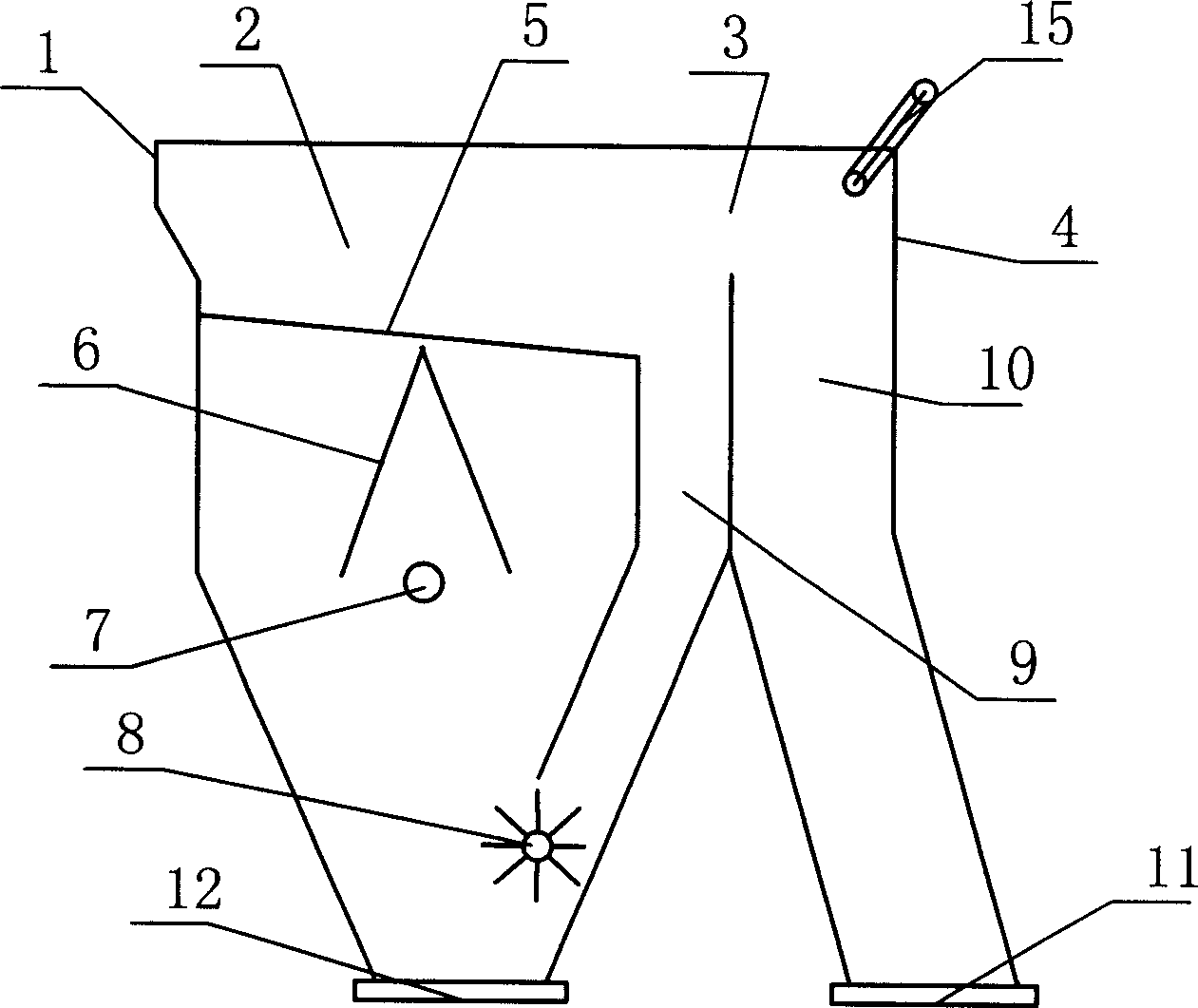

[0050] Example 3, in image 3 Among them, the third type of air chamber gangue jigging machine, the shape, structure, materials used, and functions of the single-stage jigging machine body 1 are as described in Embodiment 1. The main shape, structure, materials used, and functions of the discharge channel 4 are also as described in Embodiment 1. The difference is that a discharge height adjustment device 14 that can adjust the discharge height is installed on the feed inlet 3. .

[0051] Based on the same principle and method, the present invention can also image 3 The structure and function are realized on the gangue-discharging jig as described in Embodiment 2.

[0052] When this embodiment is working, the working steps, methods, principles, etc. are as described in Embodiment 1, the difference is that the ash content of the discharged clean coal is controlled to a certain extent through the installed discharge height adjusting device 14 that can adjust the discharge heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com