Jigging method for discharging waste rock through independent paths for discharging waste rock, and coal preparation method

A technology of gangue jigging machine and gangue channel, which is applied in the direction of chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of increasing loss and affecting recovery rate, and achieve the goal of improving recovery rate and reducing intermediate product loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

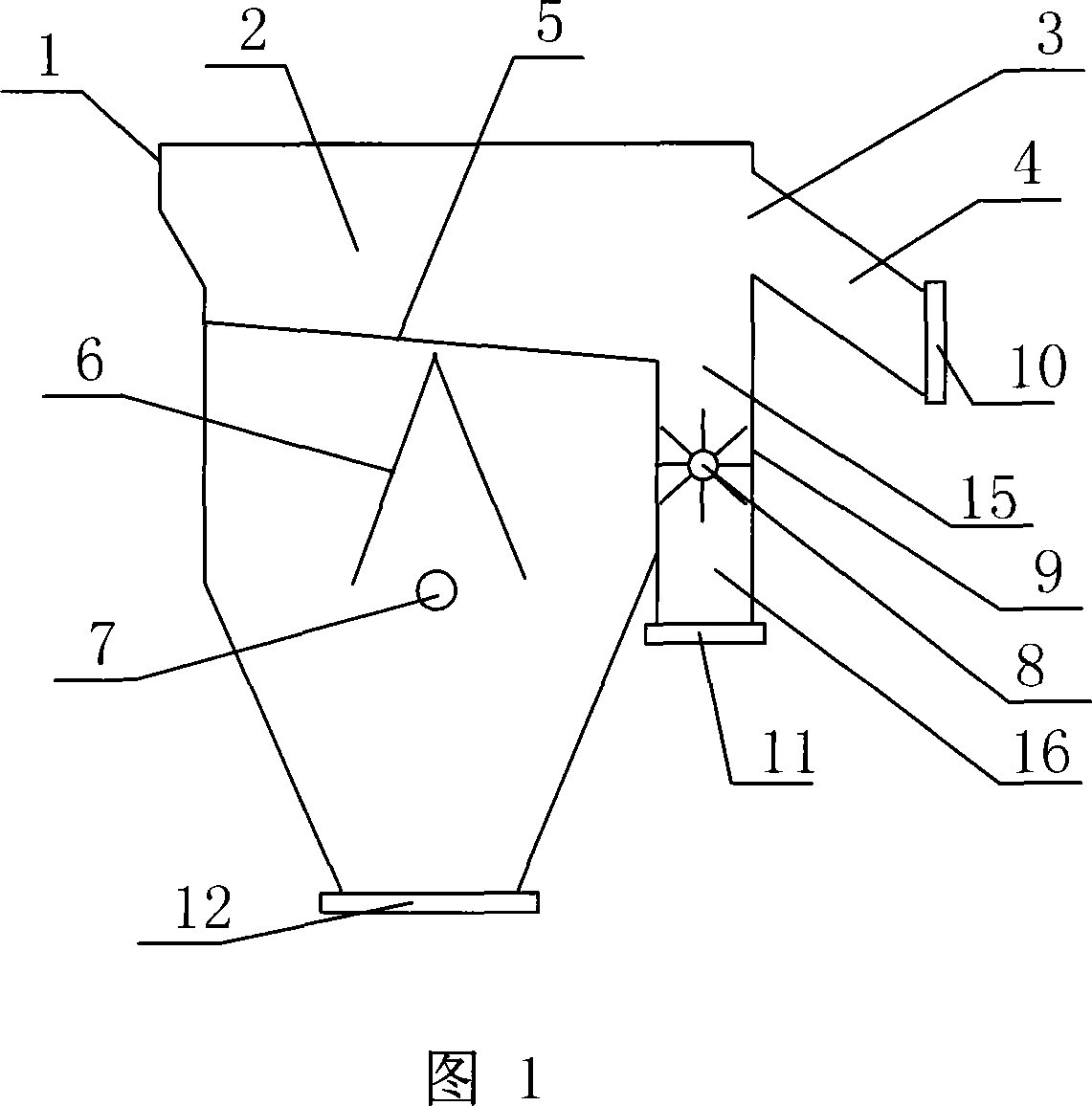

[0040] Embodiment 1, in Fig. 1, an air chamber gangue discharge jig with an independent gangue discharge channel, it includes the existing gangue discharge jig machine body 1 and an independent gangue discharge channel 9, the gangue discharge channel 9 It is a closed device with upper and lower openings. It is composed of an upper gangue inlet 15, a gangue discharge device 8, a connecting channel 16 and a lower gangue discharge outlet 11. The gangue inlet 15 of the gangue discharge channel 9 and the gangue discharge device 8 are all exactly the same as the body structure of the existing gangue-discharging jig machine, and the connecting channel 16 is drawn outwards through the body wall, and the end is provided with a gangue discharge port 11. The connecting channel 16 can be straight, can also be made into various bends, can also be made into oblique or other forms, and the section can be rectangular, circular, or other shapes .

[0041] During the work of this embodiment, t...

Embodiment 2

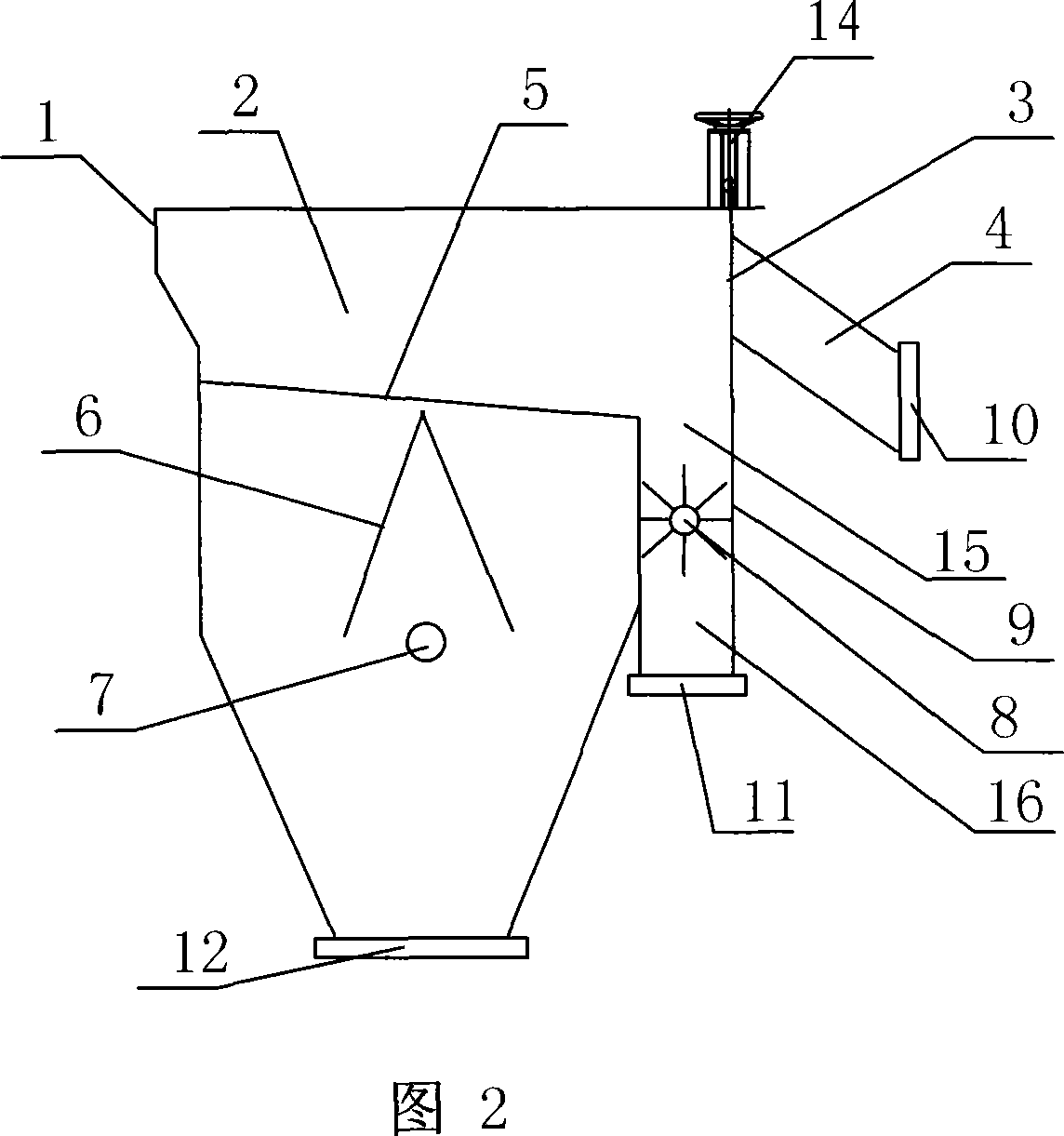

[0042] Embodiment 2, in Fig. 2, the second type of air chamber gangue discharge jig with independent gangue discharge channel, the shape, structure, materials used, functions, etc. of the gangue discharge jig body 1 are as described in embodiment 1 . The main shape, structure, materials used, and functions of the gangue discharge channel 9 are also as described in Embodiment 1, the difference is that a discharge height adjustable discharge height is installed on the clean coal inlet 3 Regulator 14.

[0043] When this embodiment is working, the working steps, methods, principles, etc. are as described in Embodiment 1, the difference is that the ash content of the discharged clean coal is controlled to a certain extent through the installed discharge height adjusting device 14 that can adjust the discharge height. Achieve on-demand nesting.

Embodiment 3

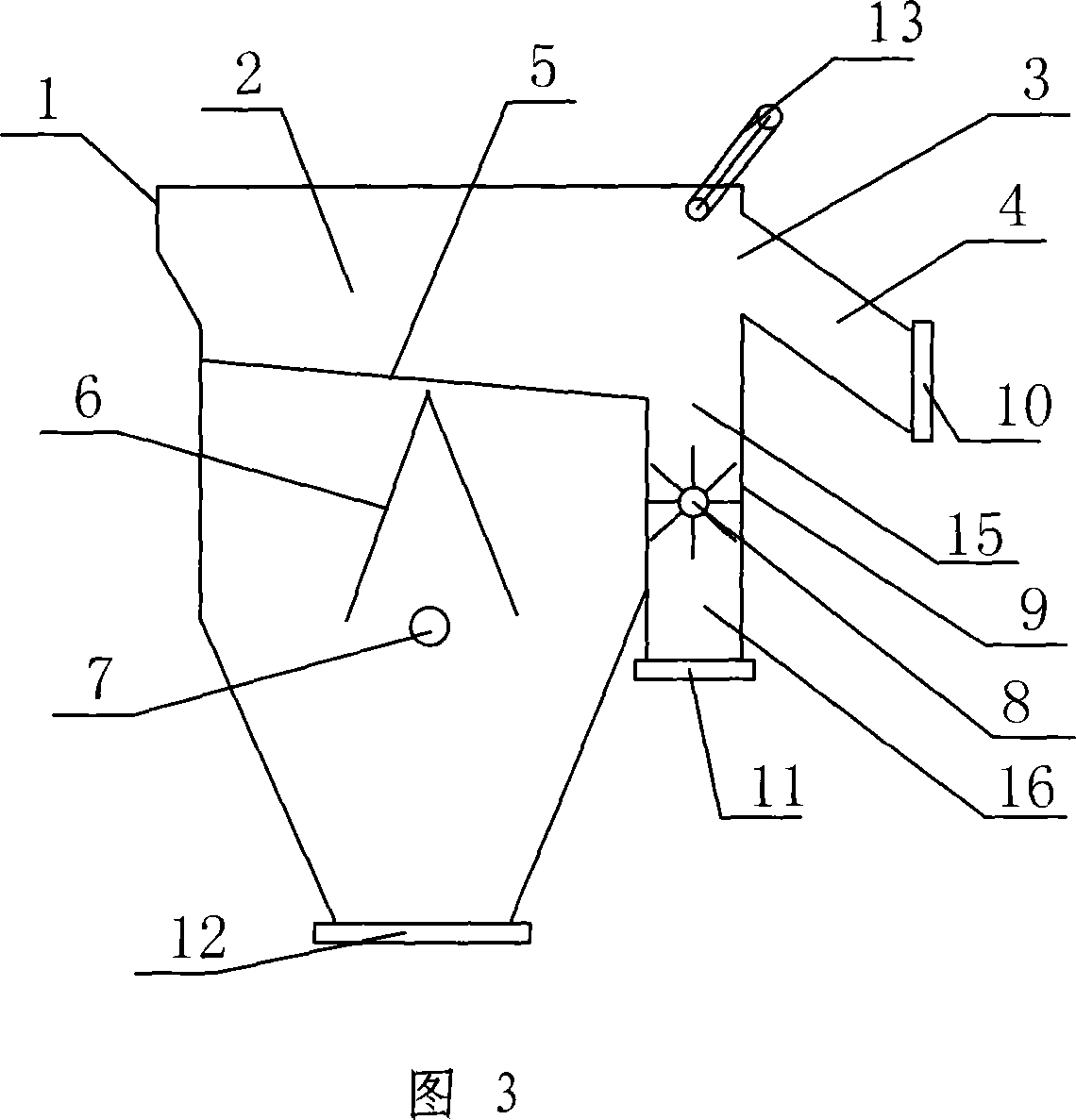

[0044] Embodiment 3, in Fig. 3, the third type of air chamber gangue ejection jig with independent gangue ejection channel, the shape, structure, materials used, functions, etc. of the gangue ejection jig body 1 are as described in embodiment 1 . The main shape, structure, materials used, and functions of the gangue discharge channel 9 are also as described in Embodiment 1, the difference is that an automatic float discharge device is added above the discharge end of the gangue discharge jig body 1 13.

[0045] Based on the same principle and method, the present invention can also realize the structure and function as shown in FIG. 3 on the gangue-discharging jig as described in Embodiment 2.

[0046] When the present embodiment works, the working steps, methods, principles, etc. are as described in Embodiment 1, the difference is that the floating objects such as wood slag floating on the water surface are discharged by the installed floating object automatic discharge devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com