Steam coal washing processing method for easy-to-argillization gangues

A processing method and thermal coal technology, which is applied in the field of thermal coal preparation, can solve problems such as improper selection and addition of reagents, increase time for gangue muddying, and increase the burden of coal slime water treatment, etc., to achieve flexible structure, lighten the burden, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

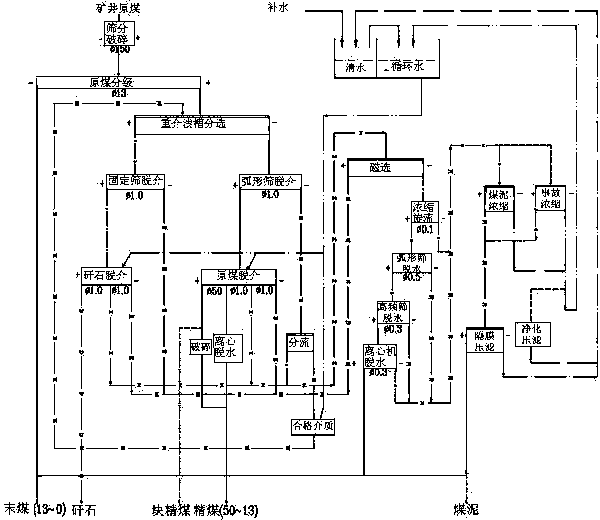

[0027] Accompanying drawing is a kind of specific embodiment of the present invention. The thermal coal washing and processing method for gangue that is easy to muddy comprises the following steps:

[0028] 1. Raw coal is crushed to less than 150mm by screening crusher.

[0029] 2. After the raw coal is broken, it is sent to the relaxation screen (screen hole 13mm, screening efficiency 95%) for dry screening: the fine coal under the screen is directly sent to the fine coal bunker as a product, and the lump coal on the screen enters the dense medium shallow tank for separation .

[0030] 3. Clean coal and gangue are obtained by sorting dense medium shallow tanks. Gangue products are obtained after the gangue is removed by the gangue removal screen. The centrifuge dehydrates and classifies, and the lump clean coal with a particle size greater than 50mm can be directly used as a product and enter the lump clean coal bunker, or it can be crushed by a crusher into a clean coal pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com