Coal pyrolysis gasification poly-generation device and process based on circulating fluidized bed

A circulating fluidized bed and polygeneration technology, which is applied in the joint production of heat, electricity, gas and activated coke, and in the field of tar, can solve the problem of high dust content in pyrolysis gas, difficulty in using dusty tar, and difficulty in purification treatment To achieve economic benefits, avoid secondary separation process, and achieve outstanding purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

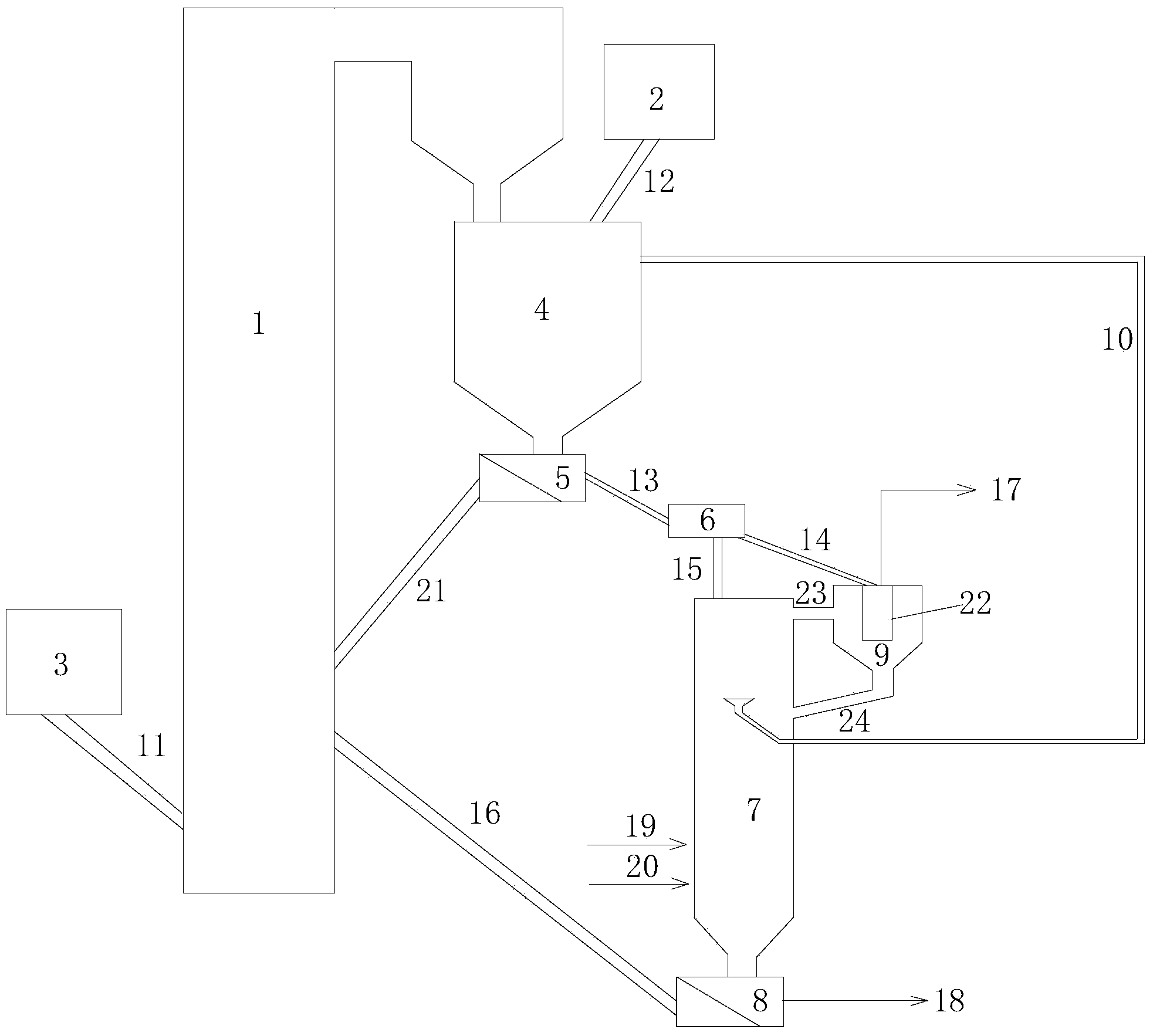

[0030] The present invention organically couples the circulating fluidized bed boiler, the moving bed pyrolysis reactor and the moving bed gasifier. As a purification device for pyrolysis gas, bed gasifier plays the role of online dust removal for pyrolysis gas. The gasified active coke is discharged from the reaction system as a by-product. In this way, through the organic combination of the three stages of pyrolysis-gasification-combustion, the hierarchical and optimal utilization of coal resources can be realized, and the joint production of heat, electricity, tar, gas, and active coke can be carried out, and at the same time, the problems of gasification gas, heat To solve the purpose of efficient purification of gas.

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

[0032] A coal pyrolysis gasification polygeneration device based on a circulating fluidized bed, comprising a circulating flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com