Coal pyrolysis and gasification polygeneration process based on circulating fluidized bed and coal pyrolysis and gasification polygeneration system based on circulating fluidized bed

A circulating fluidized bed and polygeneration technology, applied in the field of coal pyrolysis, can solve problems such as pollution and low combustion efficiency, and achieve resource and environmental problems, low energy consumption and oxygen consumption, reduced energy consumption and purification cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

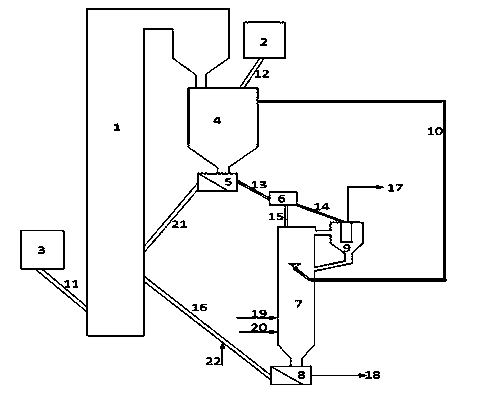

[0028] Such as figure 1 As shown, in the coal pyrolysis gasification polygeneration system based on circulating fluidized bed of the present invention, low-quality coal or low-volatile coal directly enters circulating fluidized bed boiler 1 for combustion from coal hopper 3 through coal delivery pipe 11, and utilizes circulation The high-temperature circulating ash of the fluidized bed boiler is used as a heat carrier to pyrolyze the high-volatile coal with a volatile content of 15%-45% from the pyrolysis coal hopper 2 in the moving bed pyrolysis reactor 4 to obtain pyrolysis gas, of which , the pyrolysis temperature is controlled by adjusting the ratio of circulating ash and feed coal, and the range of pyrolysis temperature is 400-700°C. The solid-phase product discharged from the pyrolysis reactor enters the sieve device 5 for sieving treatment. The opening size of the sieve plate can be adjusted within the range of 1-10mm. The circulating ash and powdery coke under the siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com