Method for treating heavy-nitrogen mother solution generated from production of dinitrodiazophenol

A dinitrodiazophenol, production process technology, applied in natural water treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. Achieve the effect of good electrical conductivity, small one-time investment and stable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

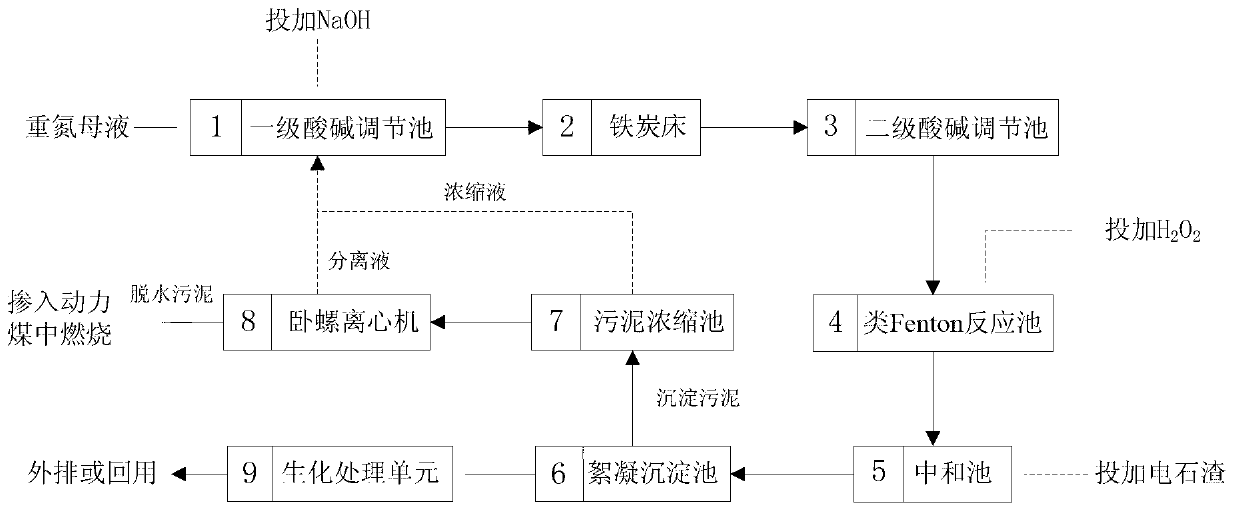

Image

Examples

Embodiment 1

[0029] The amount of diazo mother liquor processed in this embodiment is 1.0m 3 / d.

[0030] The original pH of the diazonium mother solution is 1.5-1.7, the chromaticity of the influent is 20,000 times, and the COD concentration is 1695.94mg / L. The specific implementation steps are as follows: the diazo mother liquor is collected into the first-level acid-base adjustment tank 1 through the pipeline, and the pH is adjusted to 3, and then it is lifted to the iron-carbon bed 2 by a water pump, and the Fe / C mass ratio in the iron-carbon bed 2 is 1:1. The residence time is 1h; the effluent flows into the secondary acid-base adjustment tank 3, adjusts the pH to 4, and then enters the Fenton-like reaction tank 4, and adds 30% H 2 o 2 , the reaction time is 3h; after the reaction treatment, the mother liquor flows into the neutralization tank 5, and calcium carbide slag is added to adjust the pH to 7. The supernatant enters the follow-up biochemical treatment unit 9, the COD conce...

Embodiment 2

[0032] The production amount of the diazo mother liquor that the present embodiment handles is 1.2m 3 / d.

[0033] The original pH of the diazonium mother solution is 1.5-1.7, the chromaticity of the influent is 20,000 times, and the COD concentration is 1695.94mg / L. The specific implementation steps are as follows: the diazo mother liquor is collected into the first-level acid-base adjustment tank 1 through the pipeline, and the pH is adjusted to 3, and then it is lifted to the iron-carbon bed 2 by a water pump, and the Fe / C mass ratio in the iron-carbon bed 2 is 1:1. The residence time is 1h; the effluent flows into the secondary acid-base adjustment tank 3, adjusts the pH to 3, and then enters the Fenton-like reaction tank 4, and adds 30% H 2 o 2 , the reaction time is 2h; after the reaction treatment, the mother liquor flows into the neutralization tank 5, and calcium carbide slag is added to adjust the pH to 8. The supernatant liquid enters the follow-up biochemical tr...

Embodiment 3

[0035] The production amount of the diazo mother liquor that the present embodiment handles is 1.8m 3 / d. The original pH of the diazonium mother solution is 1.5-1.7, the chromaticity of the influent is 20,000 times, and the COD concentration is 1695.94mg / L. The specific implementation steps are as follows: the diazo mother liquor is collected into the first-level acid-base adjustment tank 1 through the pipeline, and the pH is adjusted to 3, and then it is lifted to the iron-carbon bed 2 by a water pump, and the Fe / C mass ratio in the iron-carbon bed 2 is 1:1. The residence time is 1h; the effluent flows into the secondary acid-base adjustment tank 3, adjusts the pH to 3, and then enters the Fenton-like reaction tank 4, and adds 30% H 2 o 2 , the reaction time is 3h; after the reaction treatment, the mother liquor flows into the neutralization tank 5, calcium carbide slag is added to adjust the pH to 7-8, and the oxygenator installed at the bottom of the pond is used to oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com