Marine oil spill clearing and recovering device

An oil spill clean-up and recovery device technology, applied in the field of marine oil spill pollution control, can solve the problems of high water content of crude oil, biological invasion, and inability to realize leakage of crude oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

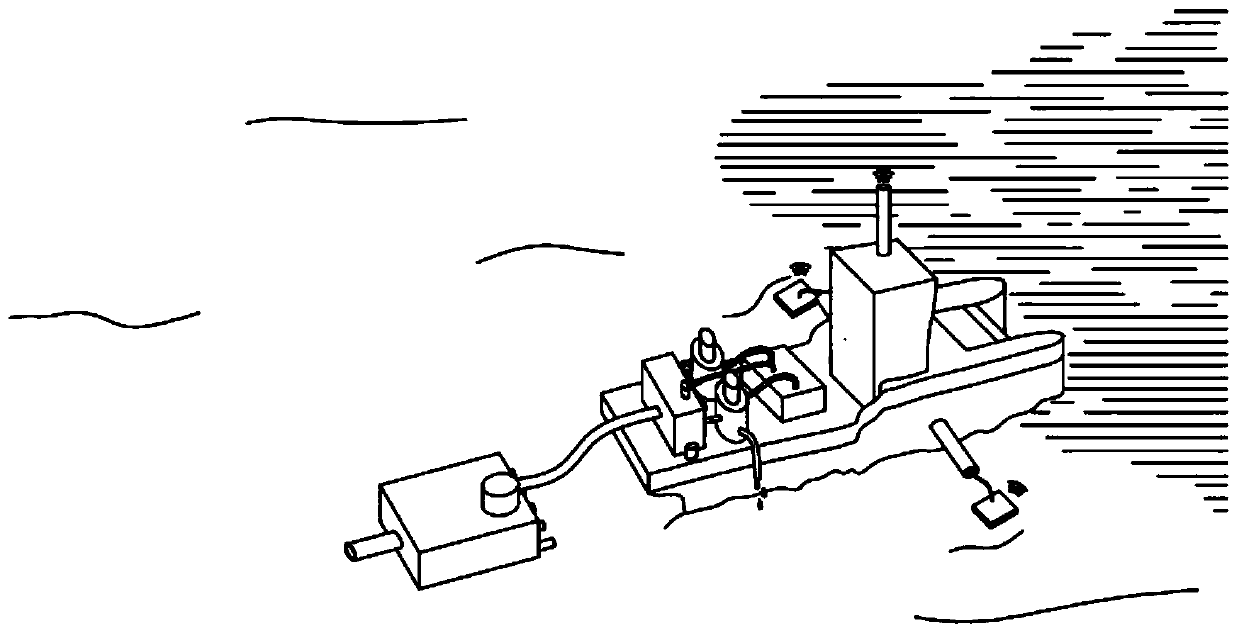

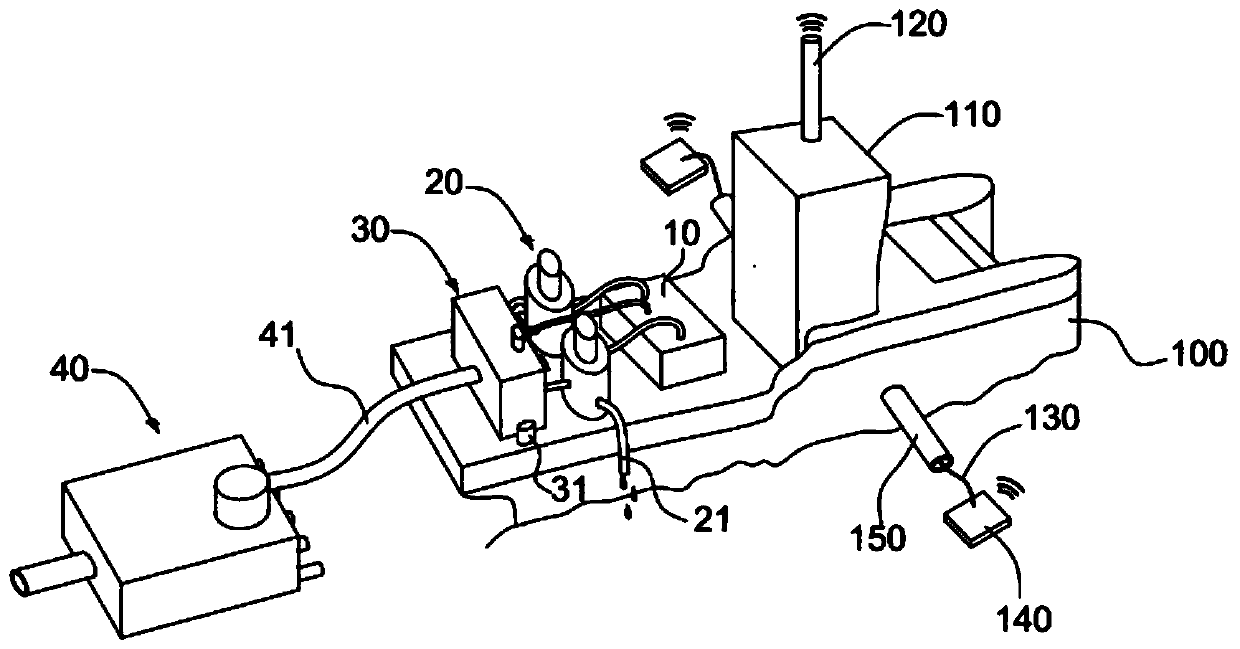

[0031] see Figure 1-8 as shown,

[0032] A marine oil spill cleaning and recovery device, comprising:

[0033] Hull 100, the first fixed rod 150 is fixedly connected to both sides of the hull 100, the end of the first fixed rod 150 is connected with the monitoring component 140 arranged in the water through the rope body 130, the monitoring component 140 and the processor 110 arranged on the hull 100 Wireless connections,

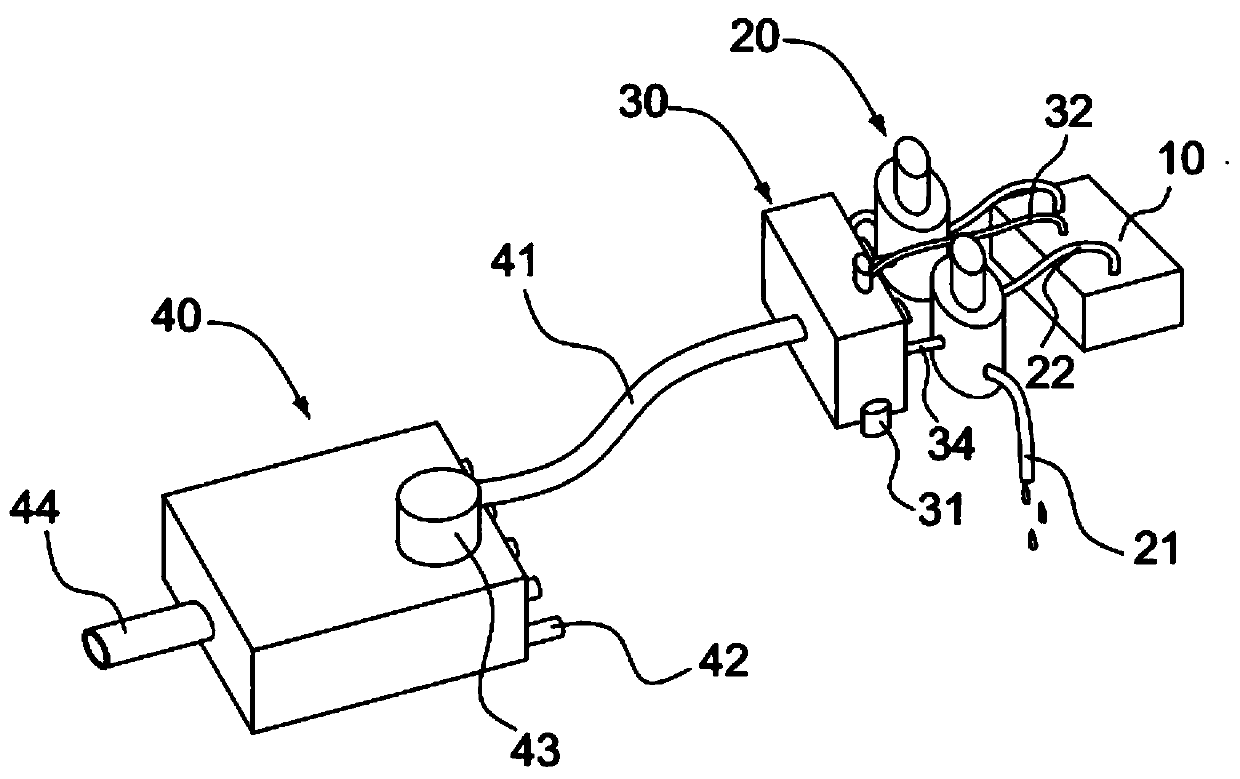

[0034] Wherein, the hull 100 is fixed with the oil collecting tank 10, the third oil filtering tank 20, and the second oil filtering tank 30, the oil collecting tank 10 is connected with the third oil filtering tank 20 through the first oil discharge pipe 22, and the third oil filtering tank 20 is connected through the second connecting pipe. 34 is connected with the second oil filter tank 30, and the second oil filter tank 30 is connected with the first oil filter tank 40 arranged on the water surface at the rear side of the stern of the hull 100 throug...

Embodiment 2

[0046]When a marine oil spill cleaning and recovery device of the present invention is actually used: after a leak occurs in the sea area, the ship hull 100 is equipped with equipment to drive to the oil spill area for emergency treatment, so as to avoid greater damage to the marine environment in the area.

[0047] First, to ensure the maximum recovery of the leaked oil by tracking the leaked oil: use the hull 100 to sail on the sea surface of the oil spill, the current velocity meter on the monitoring component 140 can drift with the sea surface water body, the current velocity meter sends the positioning signal to the processor 110, and at the same time the anemometer acquires The monitoring data is sent to the processor 110 together, and the processor judges the oil film drift speed formed by the leaked oil on the sea surface according to the data sent by the current meter and the anemometer, and combines the locator to judge the drift direction of the oil film, so as to rea...

Embodiment 3

[0051] Oil spill recovery simulation test:

[0052] Carry out group oil spill recovery simulation test in two water tanks, set up experiment group and control group separately, experiment group adopts the device of the present invention 1 and the recovery method of embodiment 2 to carry out recovery treatment, control group adopts polyurethane foam board to carry out oil adsorption Recycle.

[0053] The size of the water tank is 10 meters long x 6 meters wide x 1 meter high. The two tanks have the same size. The leaked crude oil used in the simulation is dehydrated in advance and configured as oil with a water content of 10% as the leaked crude oil. The leak point is located at the center of the tank It is set as the leak point, and oil recovery starts 4 hours after the oil spill, which is used to simulate the time it takes for the emergency unit to rush to the leaking sea area after the oil spill occurs, and the oil diffusion situation during this period. Carry out oil recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com