Dissociating, independent slurry mixing and bulk floatation process for fine grain middings

A mixed flotation and slurry mixing technology, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of fine mud pollution, etc., and achieve the effects of low power consumption, avoiding energy consumption, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

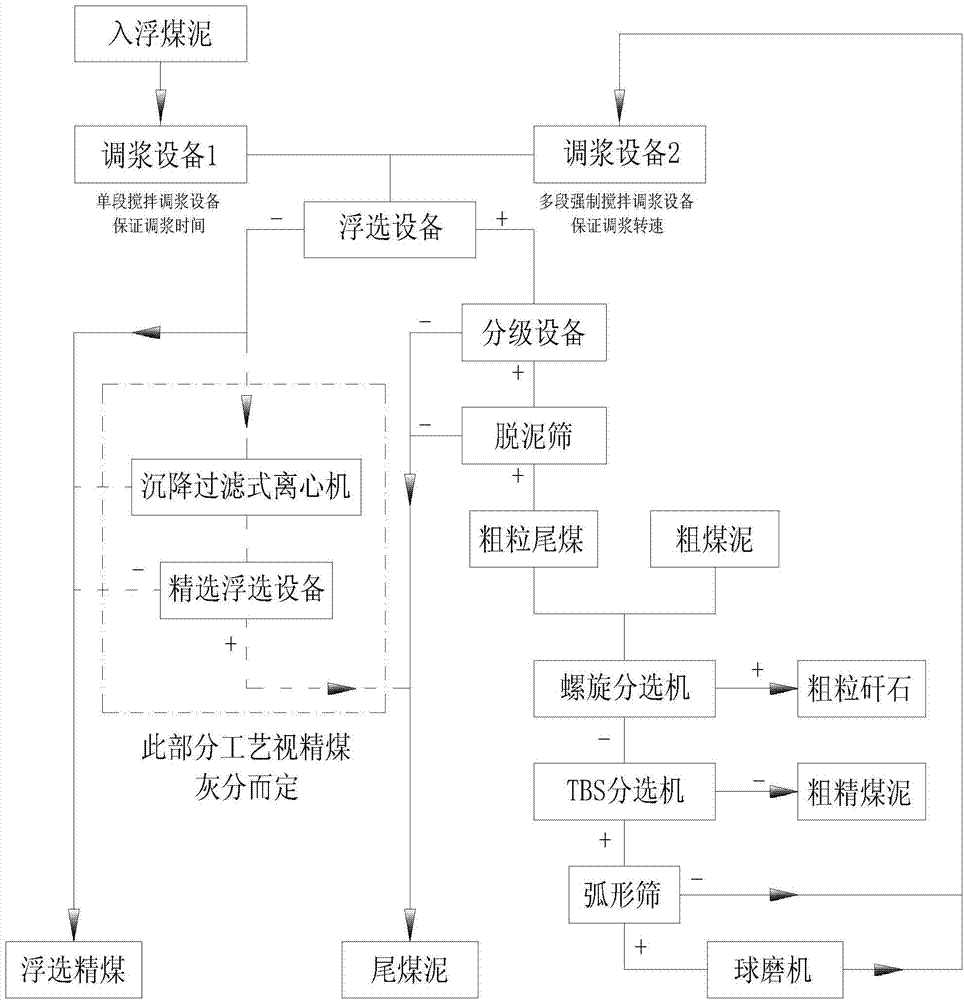

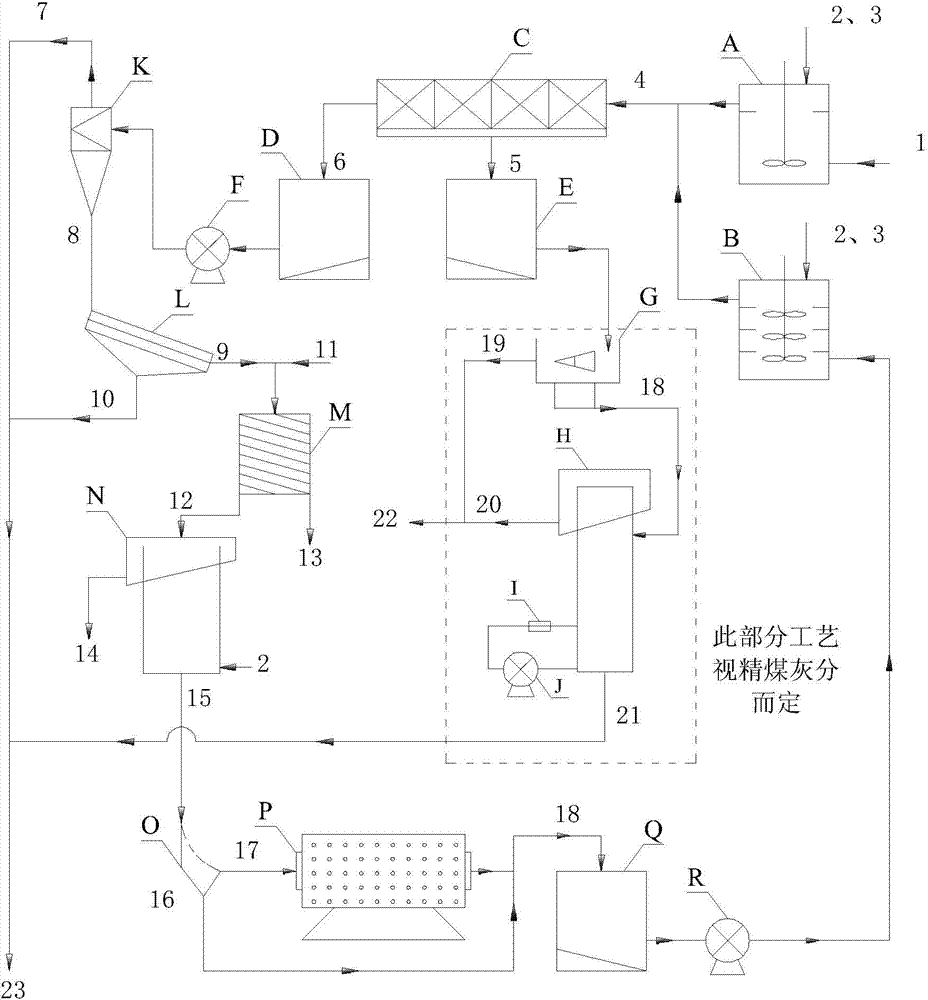

[0037] Examples: such as figure 1 As shown, in the fine-grained medium coal dissociation-independent slurry adjustment-mixed flotation process of the present invention, according to the different particle sizes of the floating coal slurry and the medium coal dissociated slurry on the different requirements for the energy input of the slurry, the floating coal slurry is given to Into the single-stage impeller mixing and mixing tank, fully ensure the mixing time (the mixing time is not less than 4min) to ensure the full adsorption of the flotation collector on the surface of the coal particles; the China Coal Mine slurry is fed into the multi-stage forced mixing and mixing equipment, The equipment is equipped with three-layer stirring impeller and the stirring speed is high (the linear speed of the stirring impeller is not less than 6m / s), so that the dissociated fine particles and the flotation collector are fully dispersed in the mixing equipment, and the fine-grained slime and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com