Novel agitating-crushing integrated agitation tank for cement

A mixing tank and cement technology, which is applied in the field of cement mixing tanks, can solve the problems that crushing and stirring cannot work together, and the inconvenience of discharging materials, etc., and achieve the effect of reducing resistance, speeding up the speed, and speeding up the crushing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

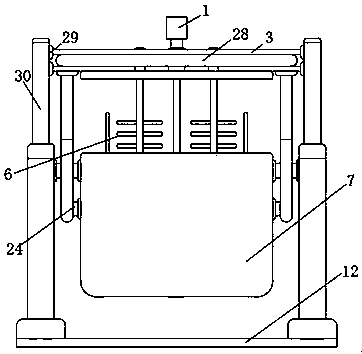

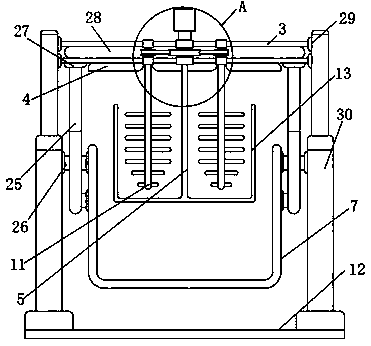

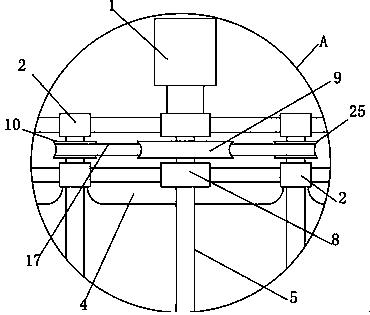

[0031] The new cement mixing and crushing integrated mixing tank includes mixing motor 1, crushing motor 14, support substrate 3, protective casing 28, hydraulic lifting rod 30, mixing tank 7 and base 12. The upper and lower sides of the middle of the protective casing 28 are fixed with the supporting substrate 3 Connection, the left and right sides of the support base plate 3 are fixedly connected with the upper end of the hydraulic lift rod 30 on the inner side, the bottom end of the hydraulic lift rod 30 is fixedly connected with the left and right sides of the upper surface of the base 12, the support base plate 3 and the middle part of the protective shell 3 and the fixed bearing 8. The upper and lower ends are fixedly connected, the inside of the fixed bearing 8 is movably sleeved with the stirring shaft 5, the upper end of the stirring shaft 5 is fixedly connected with the lower end of the stirring motor 1, and the left and right sides of the lower end of the stirring sha...

Embodiment 2

[0034] Embodiment 2: What is different based on Embodiment 1 is;

[0035] The left and right sides of the lower surface of the support substrate 3 are fixedly connected to the upper end of the rotating rod 25, the lower end of the rotating rod 25 is movably connected to the left end of the transmission rod 31, the other end of the transmission rod 31 is fixedly connected to one end of the fixed rod 24, and the middle of the left and right sides of the stirring tank 7 It is fixedly connected to the other end of the fixed rod 24, the upper ends of the left and right sides of the mixing tank 7 are fixedly connected to one end of the stabilizer rod 26, and the other end of the stabilizer rod 26 is fixedly connected to the inner side of the middle end of the hydraulic lifting rod 30;

[0036] In the process of using the present invention, after the material is added, the hydraulic lifting rod 30 is activated to drive the supporting base plate 3 to move down, thereby driving the over...

Embodiment 3

[0037] Embodiment 3: The difference based on embodiment 1 and 2 is;

[0038] The left and right sides of the lower end of the crushing shaft 11 are fixedly connected with the inner end of the impact crushing rod 6, and the impact crushing rod 6 is composed of spherical manganese steel brazing medium, spherical manganese steel brazing medium, mixed medium of spherical manganese steel brazing and manganese steel square hammer, and manganese steel square hammer from top to bottom. Made of medium and sawtooth medium;

[0039] The crushing medium on the impact crushing rod 6 of the present invention is divided into four types. According to the spatial position of the crushing rod, from top to bottom, there are spherical manganese steel brazing medium, spherical manganese steel brazing medium and manganese steel square hammer mixed medium, and manganese steel square hammer. Medium and sawtooth medium, crushing medium hits material or collides with material, the top-down impact in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com