Integrated punching-type automatic dough kneading bowl

A noodle bowl and automatic technology, which is applied in the directions of mixing/kneading with vertical installation tools, dough mixers, structural components of mixing/kneading machines, etc. The surrounding parts cannot be fully kneaded and other problems, so as to achieve the effect of speeding up the efficiency, speeding up the stirring rate and uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

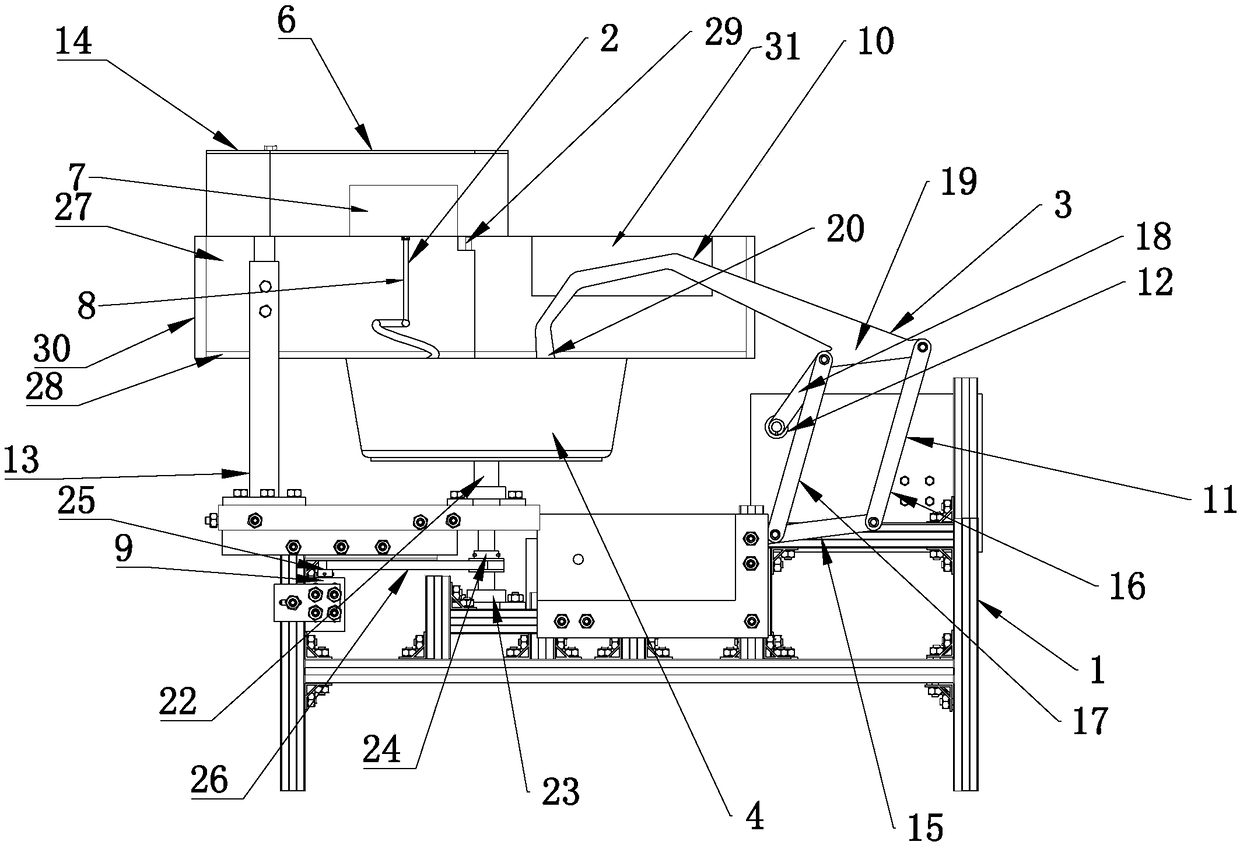

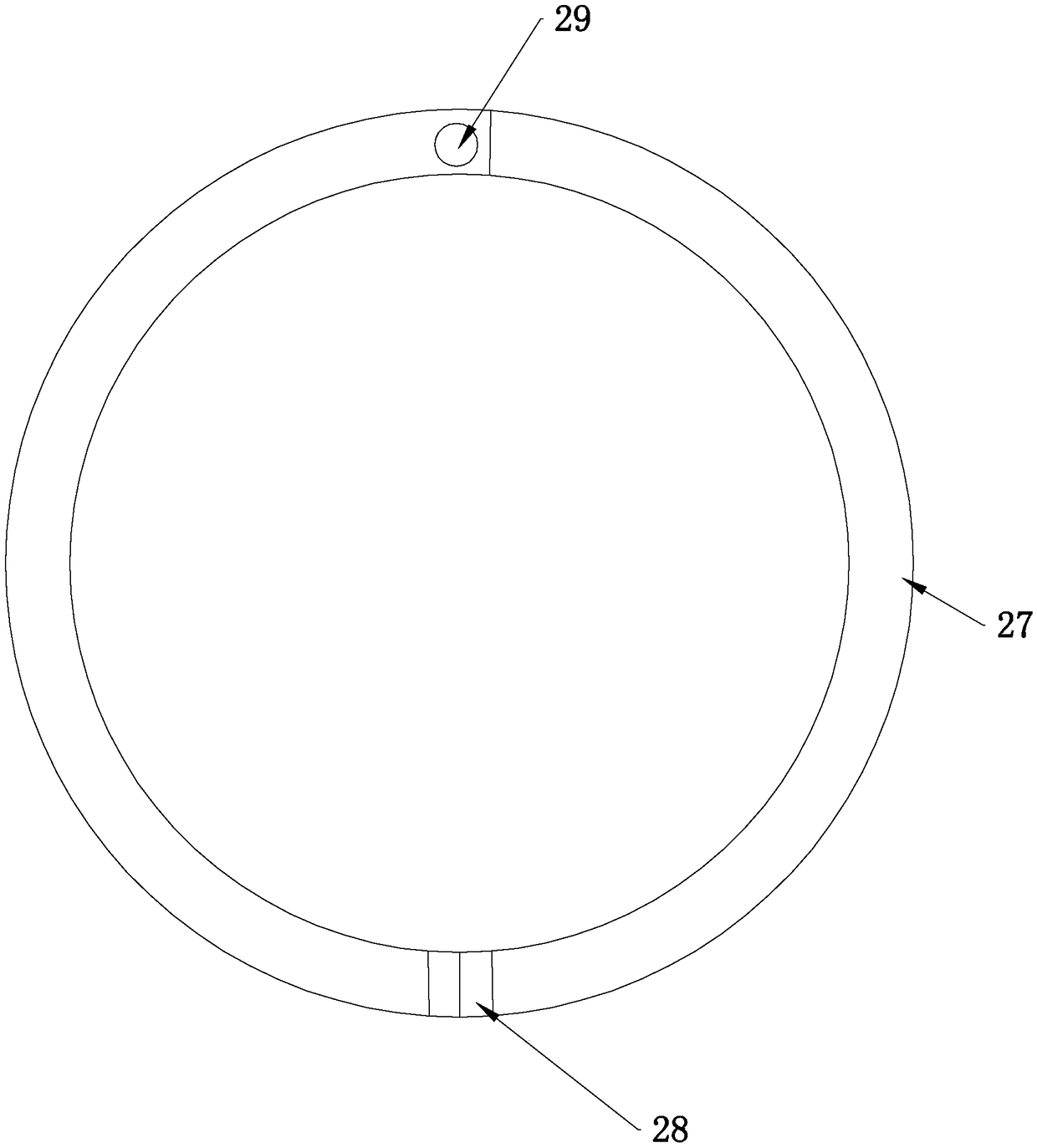

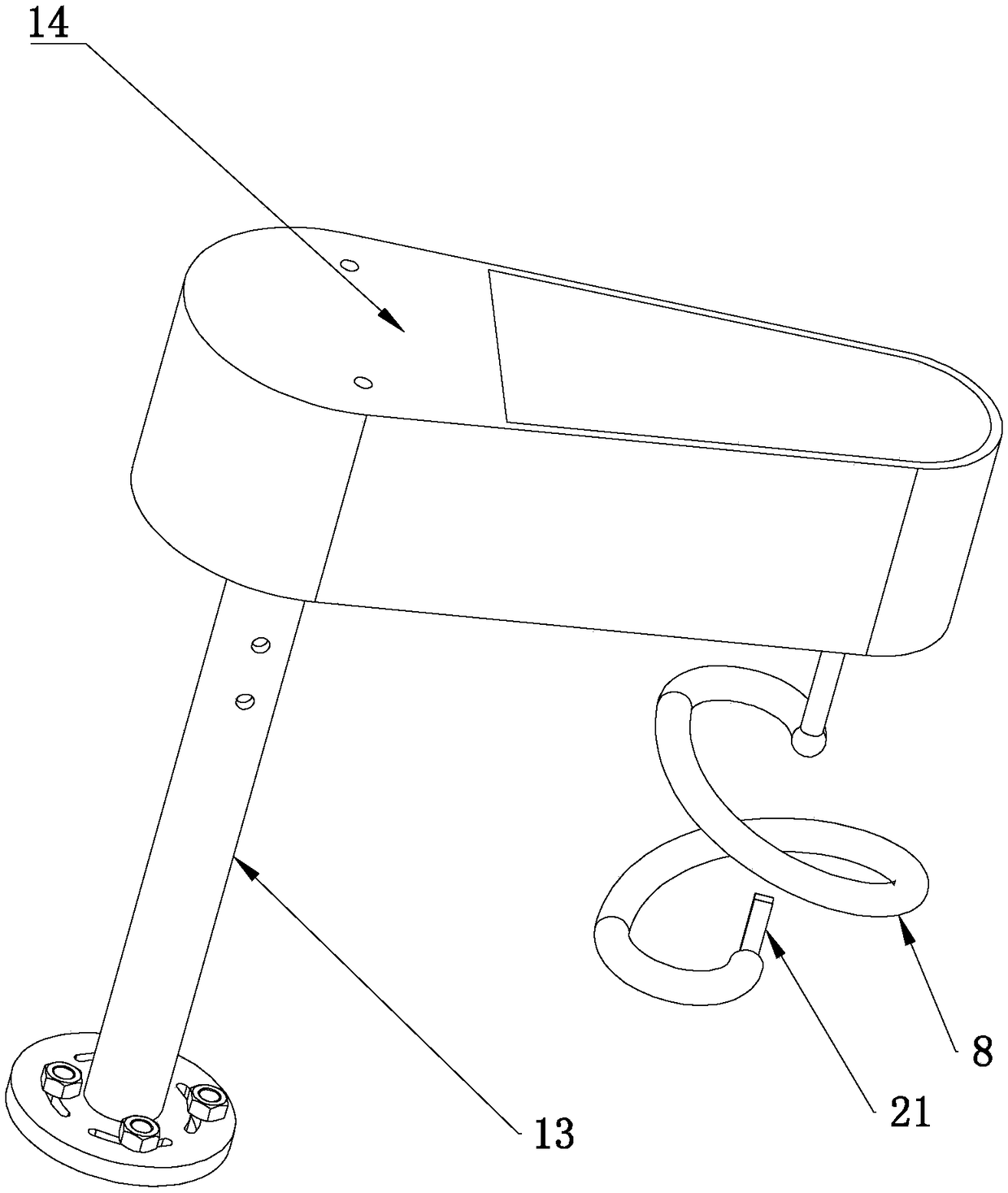

[0024] refer to Figure 1-6 As shown, a kind of integrated beating type automatic dough kneading bowl disclosed in this embodiment comprises a frame body 1, a powder mixing assembly 2 and a dough kneading assembly 3, and the frame body 1 is provided with a kneading dough bowl 4, a powder mixing assembly 2 and a kneading dough assembly The noodle assembly 3 is arranged around the kneading bowl 4, the flour mixing assembly 2 includes a first mount 6, a first drive motor 7 and a stirring rod 8, and the first drive motor 7 is installed above the kneading bowl 4 through the first mount 6 , the stirring rod 8 is connected to the first driving motor 7 on the output shaft and the first driving motor 7 drives the stirring rod 8 to rotate,

[0025] The dough kneading bowl 4 is rotatably connected to the frame body 1, and the frame body 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com