Inorganic/organic polymer composite solid electrolyte film and preparation method thereof

A solid electrolyte and polymer technology, applied in the field of lithium-ion batteries, can solve the problems of difficult processing of electrolyte films, difficulty in resisting lithium dendrite growth, low conductivity, etc., and achieve spatial network structure stability, electrochemical and interface stability Good, the effect of improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing an inorganic / organic polymer composite solid electrolyte film, comprising the following preparation steps:

[0027] After mixing the raw materials, casting and drying in sequence to obtain an inorganic / organic polymer composite solid electrolyte film, the raw materials include an inorganic solid electrolyte, a polymer matrix and an organic solvent;

[0028] The inorganic solid electrolyte has a chemical composition shown in formula I: Li 1+x al x Ti 2-x (PO 4 ) 3 Formula I, 0.1≤x≤0.5;

[0029] The mass of the inorganic solid electrolyte is 5% to 15% of the mass of the polymer matrix;

[0030] The mass of the organic solvent is 60-90% of the mass of the polymer matrix.

[0031] In the present invention, the amount of the inorganic solid electrolyte is preferably 10% to 13% of the mass of the polymer matrix.

[0032] The inorganic solid electrolyte is preferably Li 1.2 al 0.2 Ti 1.8 (PO 4 ) 3 , Li 1.3 al 0.3 Ti ...

Embodiment 1

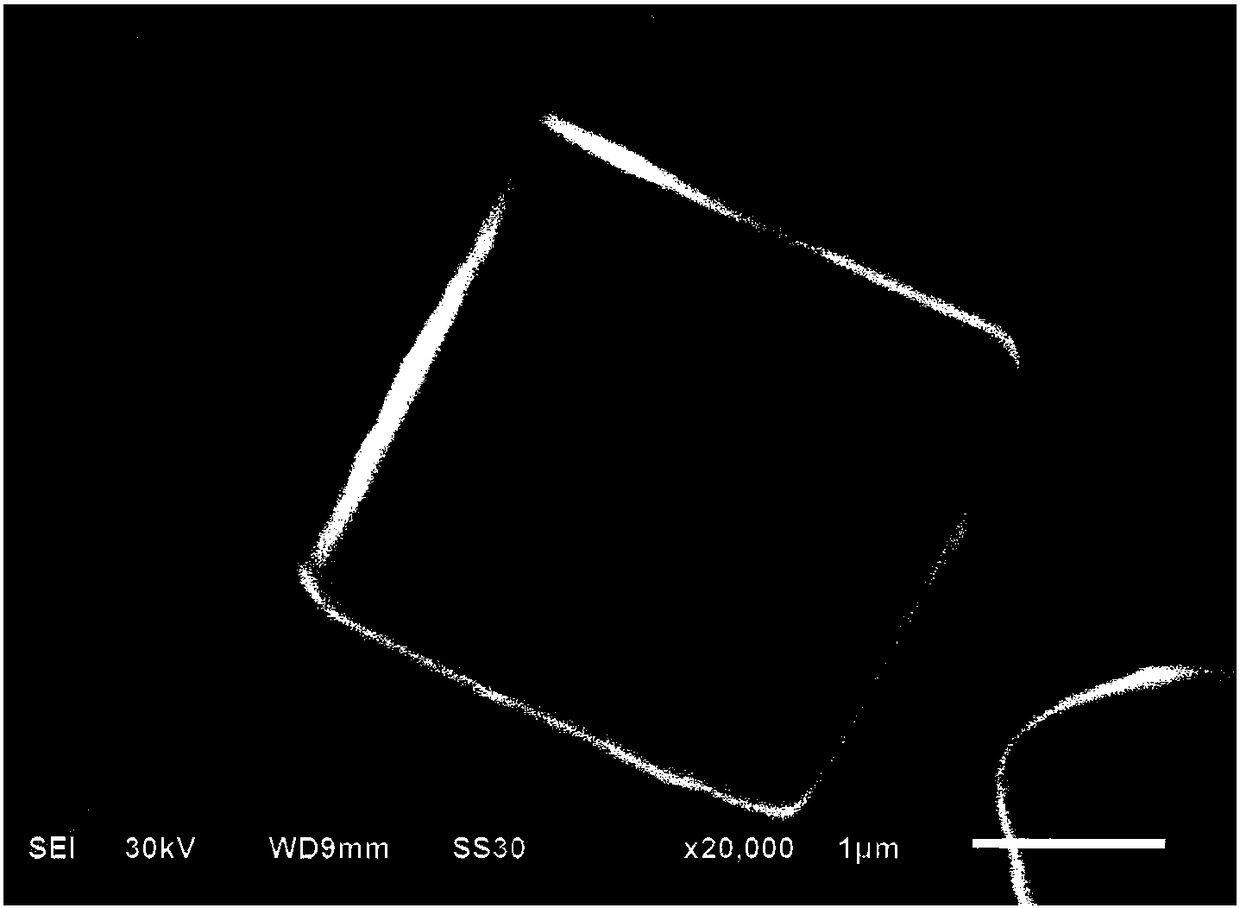

[0058] Weigh 0.6545g LiOH·H 2 O was first dissolved in deionized water, and then 0.1529 g Al was weighed 2 o 3 , 1.3578gTiO 2 and 2.94g H 3 PO 4 Add to the above solution and stir magnetically. The mixture was heated to 120°C to remove excess water until a viscous paste formed. Calcined at 850°C for 4h at a heating rate of 2°C / min in a muffle furnace, and cooled naturally to obtain the inorganic solid electrolyte Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 , referred to as LATP. The obtained LATP was wet-milled in an agate ball mill jar at a speed of 500r / min for 10h, and dried at 100°C to obtain LATP powder. The scanning electron microscope picture of the powder is as follows: figure 1 shown.

[0059] Weigh 0.025g of the above-prepared LATP powder and add it to 4.5g DMF and stir at room temperature for 48h, then add 0.5g of vinylidene fluoride-hexafluoropropylene copolymer and magnetically stir at 50°C for 2h to form a homogeneous polymer solution without adding DBP . Spread...

Embodiment 2

[0061] LATP powder was prepared as described in Example 1.

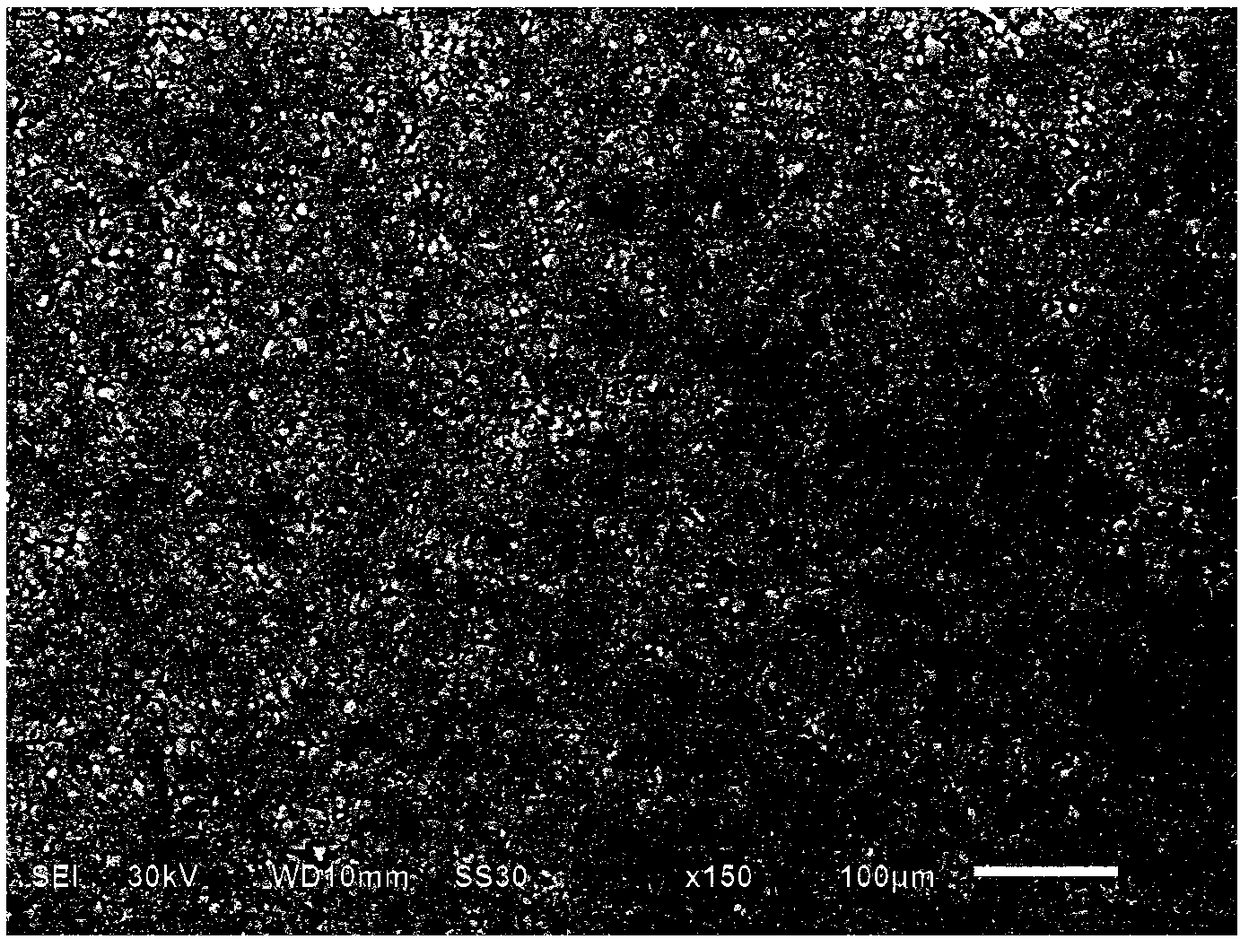

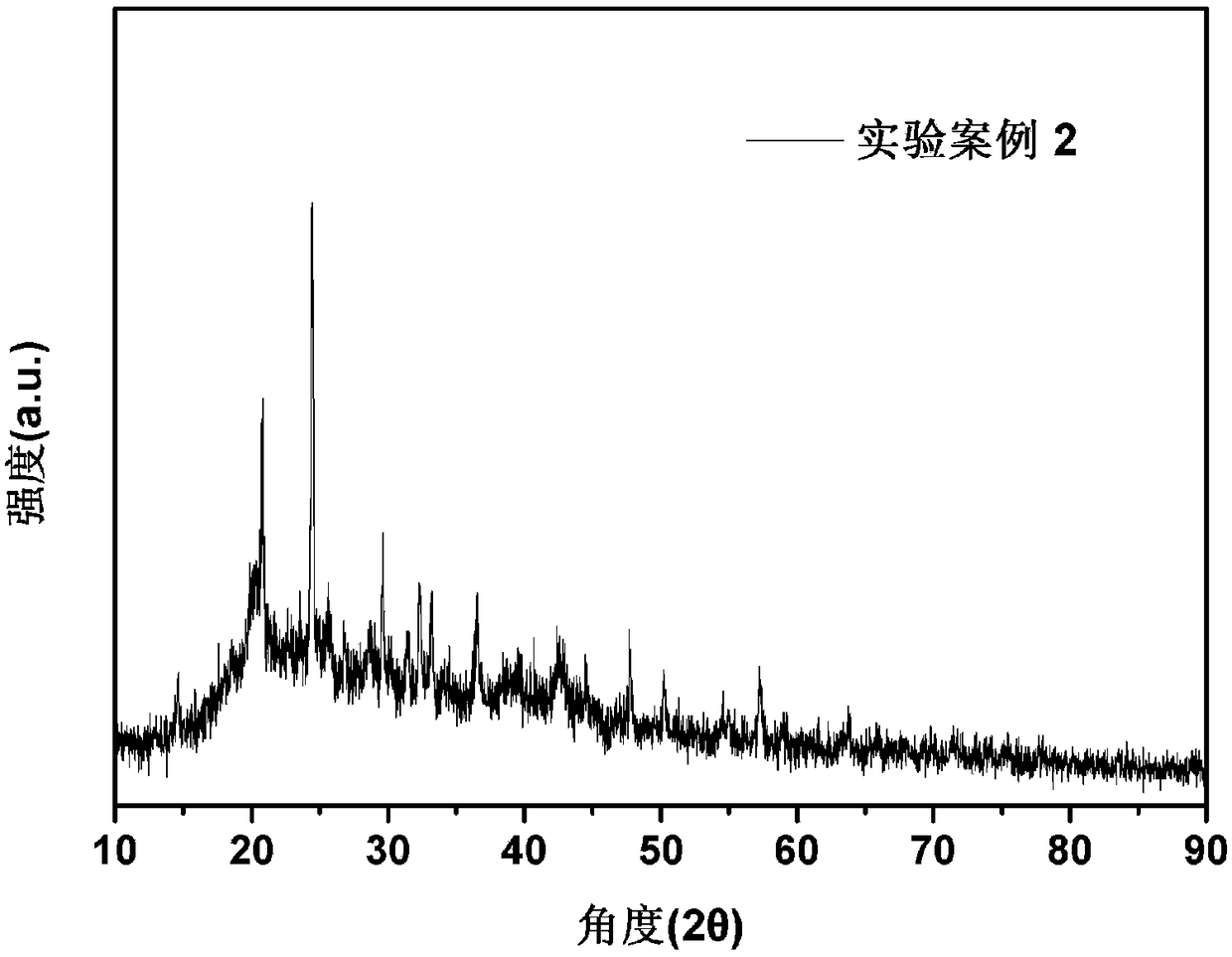

[0062] Weigh 0.025 g of LATP powder prepared under the above conditions and add it to 4.5 g DMF, stir at room temperature for 48 h, then add 0.5 g of vinylidene fluoride-hexafluoropropylene copolymer and magnetically stir for 2 h at 50° C. to form a homogeneous mixture. Then 0.75g DBP was added and stirring was continued for 1.5h to form a homogeneous polymer solution. Spread the obtained polymer mixture on a clean glass slide to form a film, transfer it to a vacuum drying oven at 50°C for 24 hours, soak it in alcohol to remove the DBP plasticizer, and then dry it in vacuum at 60°C for 12 hours to obtain an inorganic / organic Composite polymer electrolyte membrane, (the SEM image of composite polymer electrolyte is shown in figure 2 As shown, the surface of the electrolyte is evenly distributed, and there are certain pores that are conducive to the transport of Li+. XRD picture as shown image 3 As shown, the diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com