Method for improving dry-friction wear performance of aluminum-based composite material

An aluminum-based composite material and wear performance technology, applied in the field of aluminum-based composite materials, can solve the problems of weakened lubrication, subsurface fracture, weak interface bonding, etc., and achieve the effects of preventing agglomeration, reducing high-temperature oxidation, and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] Specific implementation mode 1: The method for improving the dry friction and wear performance of aluminum-based composite materials in this implementation mode is completed according to the following steps:

[0036] Step 1. Take the mass of required carbon nanotubes and silicon carbide whiskers respectively according to the designed volume fraction, and the calculation formula is where V pre is the designed prefabricated block volume, is the volume fraction of the designed carbon nanotubes or silicon carbide whiskers, ρ is the density of the designed carbon nanotubes or silicon carbide whiskers, where V pre The unit is cm 3 , the unit of ρ is g / cm 3 , the density of carbon nanotubes is 1.3g / cm 3 , the density of silicon carbide whiskers is 3.2g / cm 3 , the unit of m is g;

[0037]The design prefabricated block size is φ50mm×25mm, V pre =49cm 3 , the volume fraction ratio of carbon nanotubes to silicon carbide whiskers is 1:1 and the overall volume fraction is ...

specific Embodiment approach 2

[0046] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 7, high temperature heat exposure superimposes peak aging treatment, the heat treatment process is 580°C / 1.5h, 160°C / 5h, and the cooling rate between the two temperatures is 4°C / min, and finally cooled down to room temperature with the furnace.

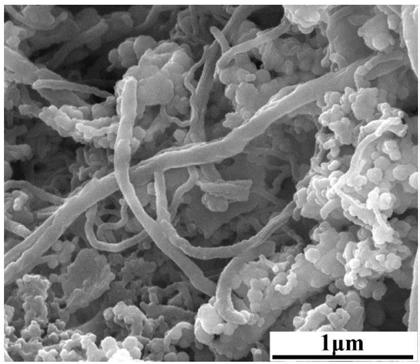

[0047] The scanning electron microscope (SEM) topography photo of carbon nanotubes after electroless nickel plating in the present embodiment is as follows figure 1 shown. From figure 1 It can be seen that a uniform nickel metal layer is attached to the surface of the carbon nanotubes, and a small amount of nickel particles can be seen between the carbon nanotubes.

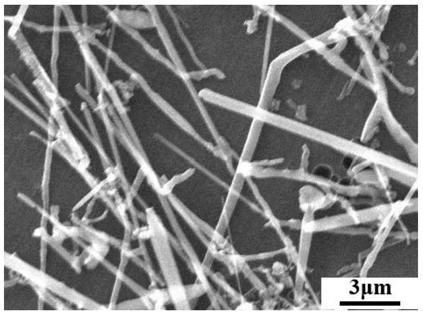

[0048] Utilize the silicon carbide whisker scanning electron microscope (SEM) topography photograph after pretreatment of the method of this embodiment as follows figure 2 As shown, the whisker dispersibility is good and there are few impurities.

[0049] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com