Processing technology for metal composite material

A technology of metal composite materials and processing technology, which is applied in the field of processing technology of fiber-reinforced metal matrix composite materials, can solve problems such as high cost, complicated process, and complicated packaging operation, and achieve improved performance, less interface reaction, and improved internal defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with examples.

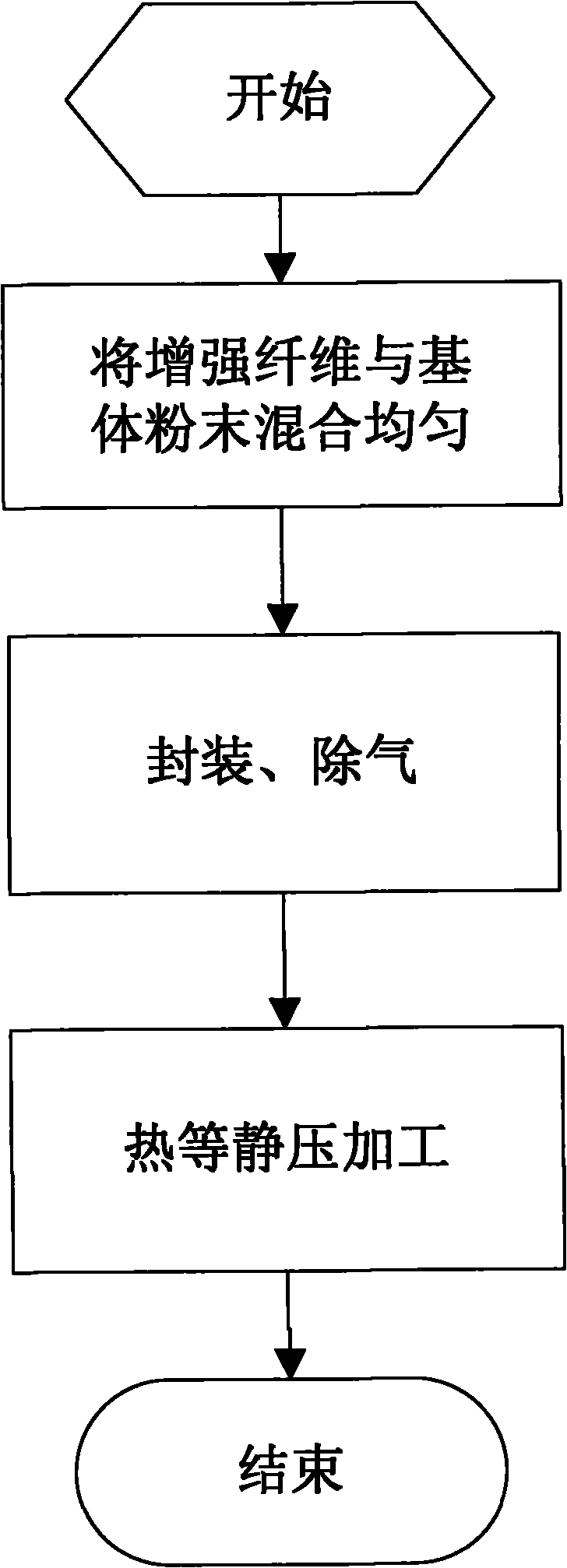

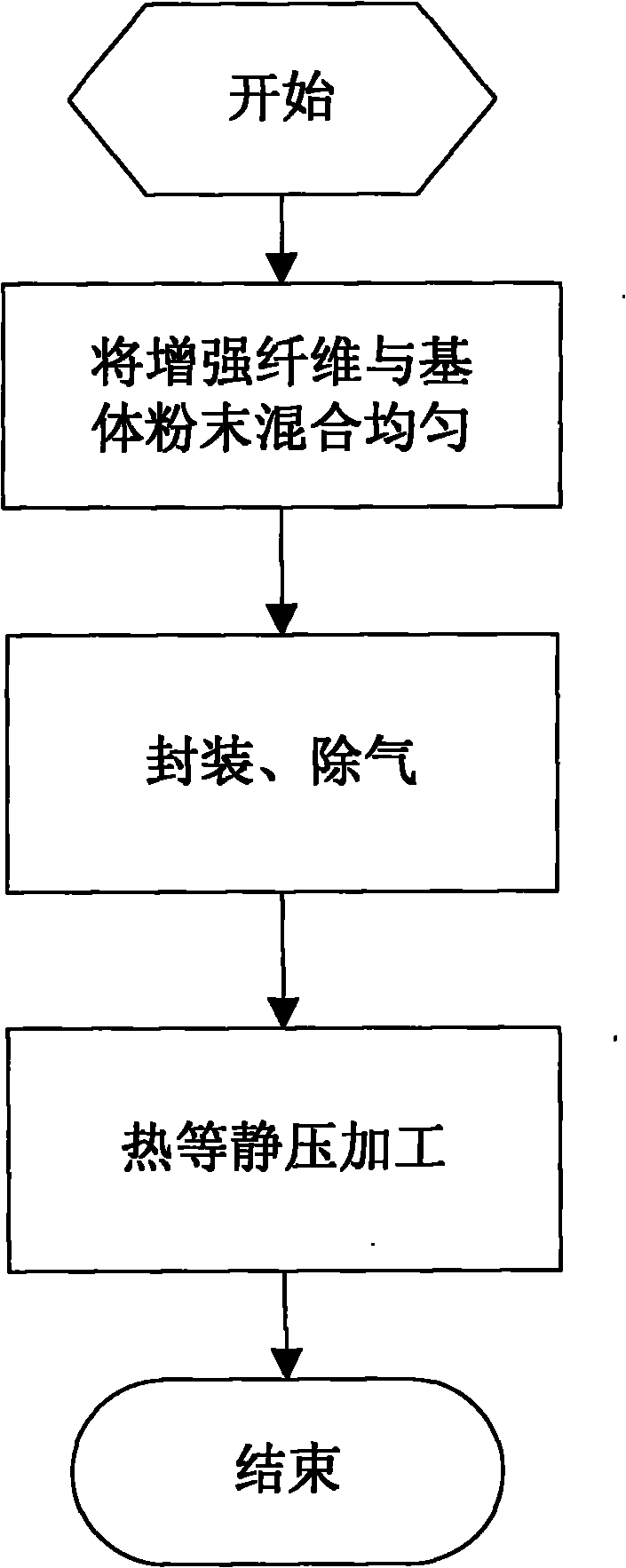

[0011] The processing technology described in the present invention can be applied not only to continuous, long-fiber-reinforced, but also to short-fiber, particle or whisker-reinforced metal matrix composite materials. The powder wood metallurgy process of short fibers, particles or whiskers reinforced metal matrix composites is mainly divided into two parts. First, the reinforcing fibers (short fibers, particles or whiskers) are mixed with metal powder evenly, mostly by mechanical mixing; then Carry out packaging, degassing, and then perform hot isostatic pressing to improve the compactness of the composite material. Specifically, in the embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com