Electromagnetic pulse forming device and method for aluminum-based carbon fiber reinforced composite material

A technology for reinforcing composite materials and aluminum-based carbon fibers, which is applied in the field of metal-matrix composite materials processing equipment, can solve the problems of difficult control of interface reactions, complex equipment and processes, and small thermal expansion coefficients, and is suitable for mass production. The effect of short generation and forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

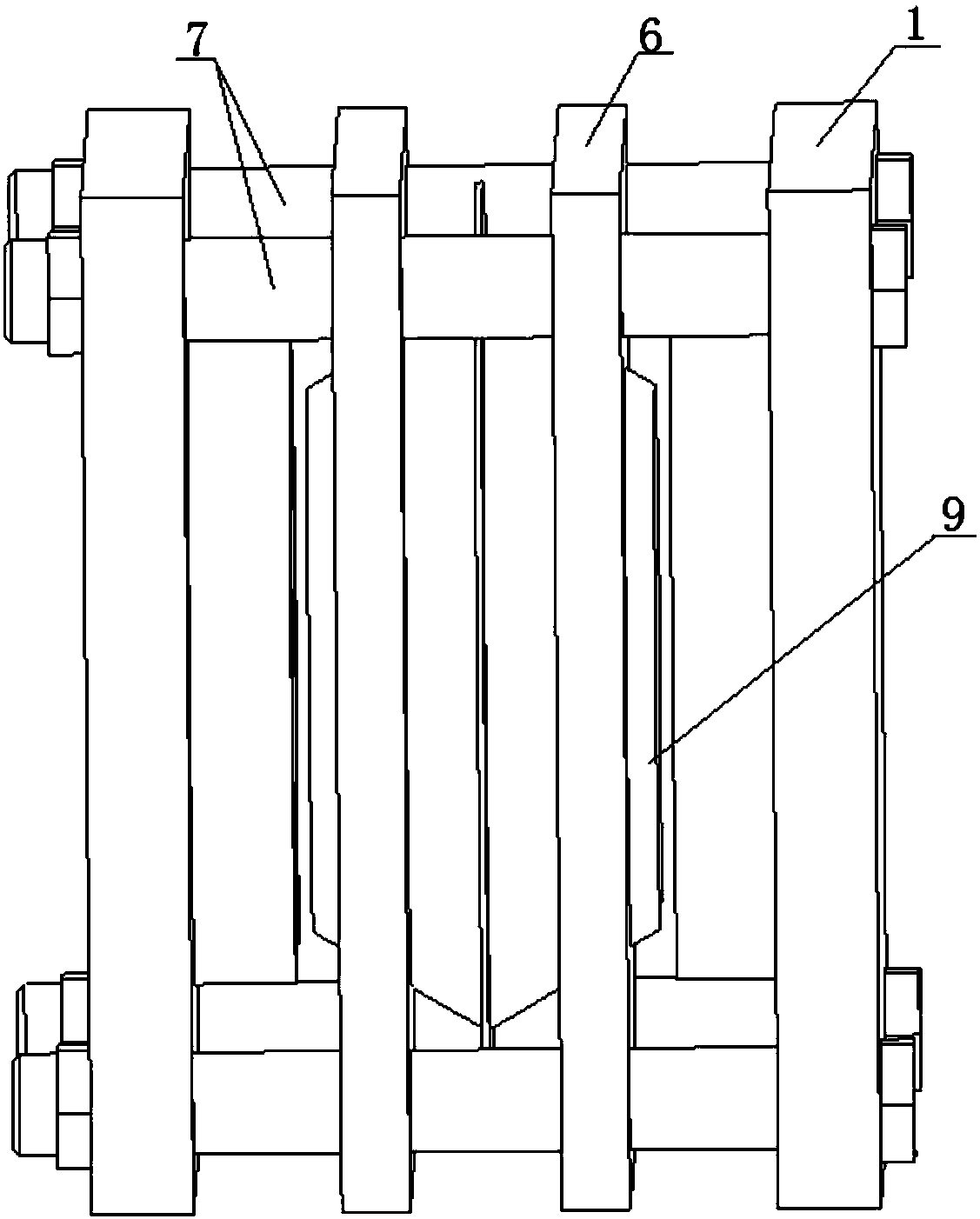

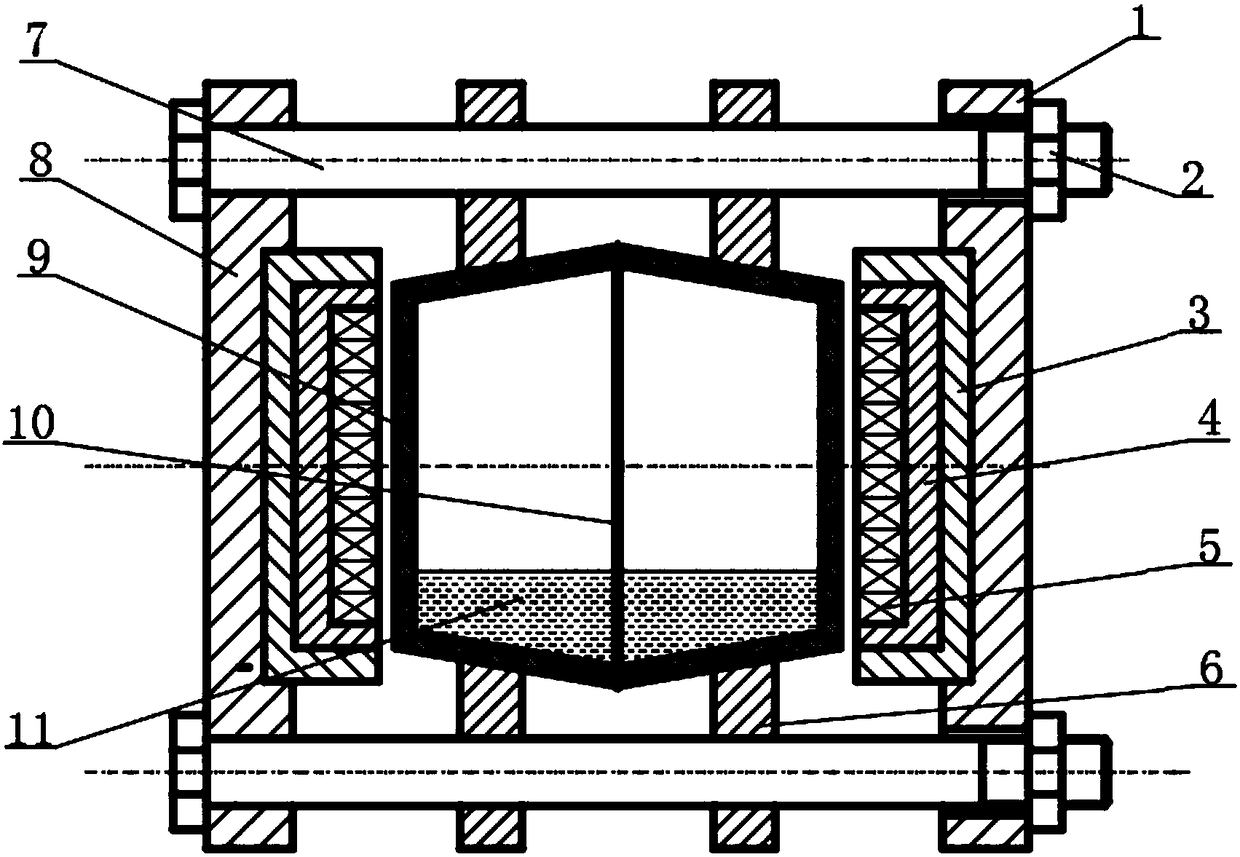

[0031] refer to Figure 1 to Figure 4As shown, the electromagnetic pulse forming device of an aluminum-based carbon fiber reinforced composite material in an embodiment provided by the present invention includes a crucible container, a crucible fixing device and a carbon fiber cloth 10, the crucible container is fixed on the crucible fixing device, and the carbon fiber cloth 10 is vertical It is directly installed in the crucible container, and the inner cavity of the crucible container is divided into two. There are coils on both sides of the outer crucible container. The inner cavity of the crucible container is filled with metal aluminum or aluminum alloy melt. The two coils are distributed on the carbon fiber Both sides of the cloth 10; through the eddy current generated after the coils on both sides are energized, the Lorentz force generated by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com