Additive Co3O4-contained lithium-sulfur battery positive electrode material and preparation method

A lithium-sulfur battery and cathode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor battery cycle performance and low utilization rate of electrode active materials, so as to prolong battery life, improve electrochemical performance, The effect of inhibiting oxidative activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

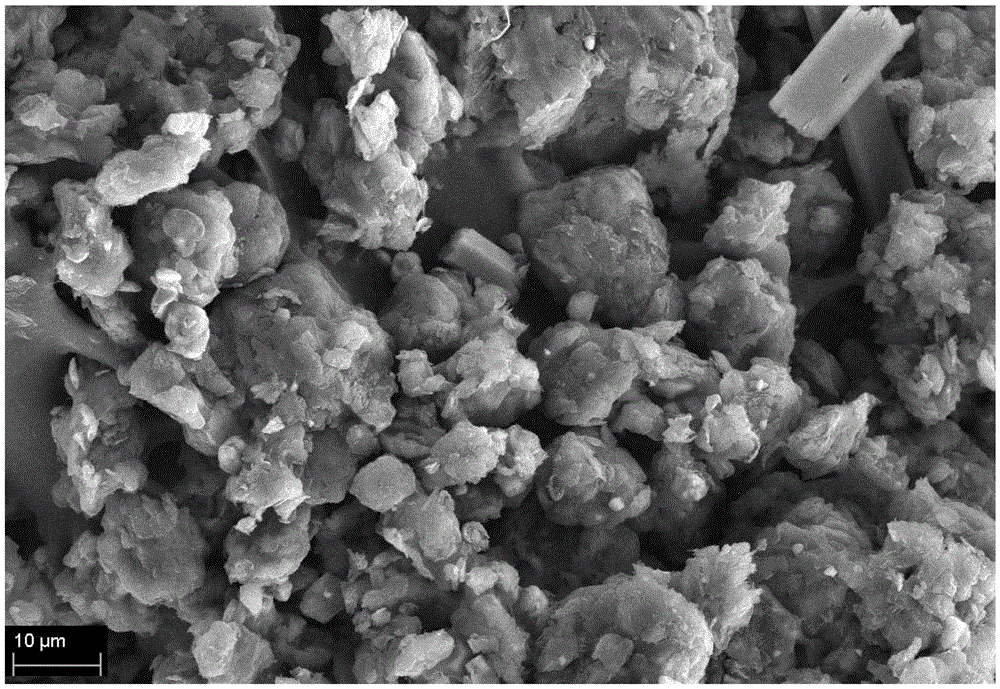

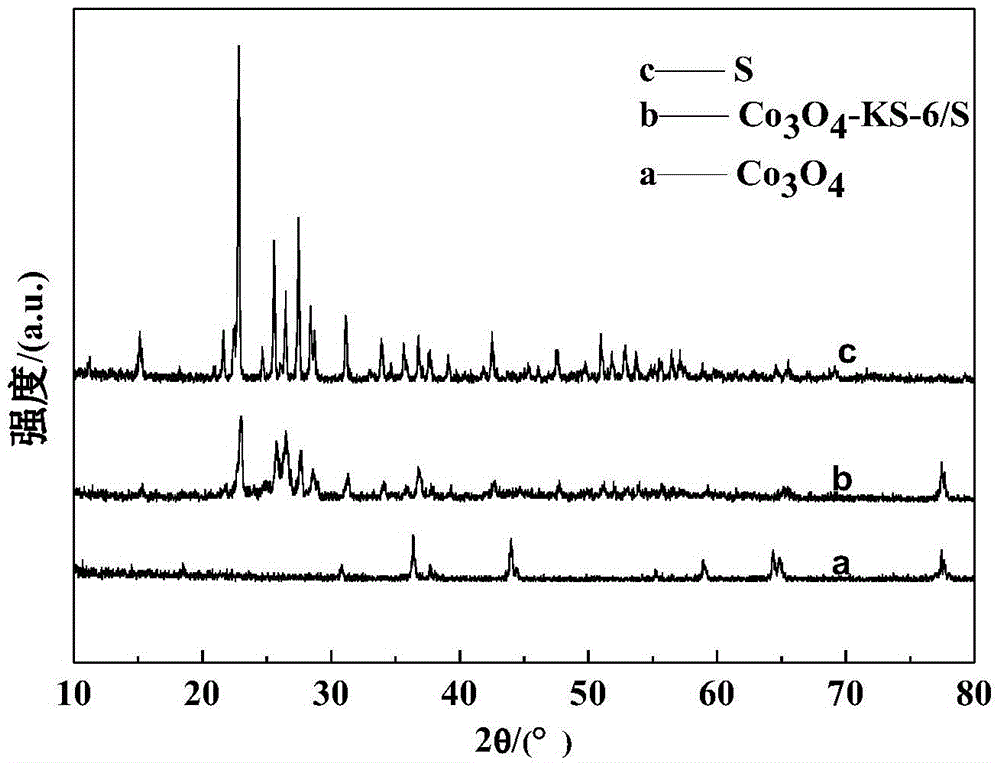

[0026] Step 1) Combine KS-6 with Co(NO 3 ) 2 ·6H 2 O was put into a ball mill jar at a mass ratio of 1:1, an appropriate amount of ethanol was added, and after wet mixing for 1.5 hours, it was dried in an oven at 70°C for 12 hours.

[0027] Step 2) The mixture obtained in step 1) was calcined at a high temperature of 300°C under nitrogen in a tube furnace for 5 hours, and the product obtained after calcination contained KS-6 and Co 3 o 4 (by Co(NO 3 ) 2 ·6H 2 O produced by decomposition) has a mass ratio of 1:0.25.

[0028] Step 3) Mix and grind the calcined product of step 2) with sulfur at a ratio of 1:1, place it in a hydrothermal reaction kettle, and after passing argon gas for 20 minutes, place the reaction kettle at 156°C for 10 hours to obtain the additive containing co 3 o 4 cathode materials for lithium-sulfur batteries.

Embodiment 2

[0030] Step 1) Combine KS-6 with Co(NO 3 ) 2 ·6H 2O was put into a ball mill jar at a mass ratio of 1:0.5, and an appropriate amount of ethanol was added. After wet mixing for 2 hours, it was dried in an oven at 70°C for 15 hours.

[0031] Step 2) Calcining the mixture obtained in step 1) in a tube furnace at 400°C under nitrogen for 4 hours at a high temperature, the product obtained after calcination is KS-6 and Co 3 o 4 (by Co(NO 3 ) 2 ·6H 2 O produced by decomposition) has a mass ratio of 1:0.1.

[0032] Step 3) Mix and grind the calcined product of step 2) with sulfur at a ratio of 1:1.5, place it in a hydrothermal reaction kettle, and after passing in argon for 25 minutes, place the reaction kettle at 155°C for 12 hours to obtain the additive-containing co 3 o 4 cathode materials for lithium-sulfur batteries.

Embodiment 3

[0034] Step 1) Combine KS-6 with Co(NO 3 ) 2 ·6H 2 O was put into a ball mill jar at a mass ratio of 1:0.75, an appropriate amount of acetone was added, and after wet mixing for 1.5 hours, it was dried in an oven at 70°C for 12 hours.

[0035] Step 2) The mixture obtained in step 1) was calcined at a high temperature of 250°C under nitrogen in a tube furnace for 7 hours, and the product obtained after calcination contained KS-6 and Co 3 o 4 (by Co(NO 3 ) 2 ·6H 2 O produced by decomposition) has a mass ratio of 1:0.23.

[0036] Step 3) Mix and grind the calcined product of step 2) with sulfur at a ratio of 1:2, place it in a hydrothermal reaction kettle, pass argon gas for 30 minutes, and place the reaction kettle at 156°C for 12 hours to obtain co 3 o 4 cathode materials for lithium-sulfur batteries.

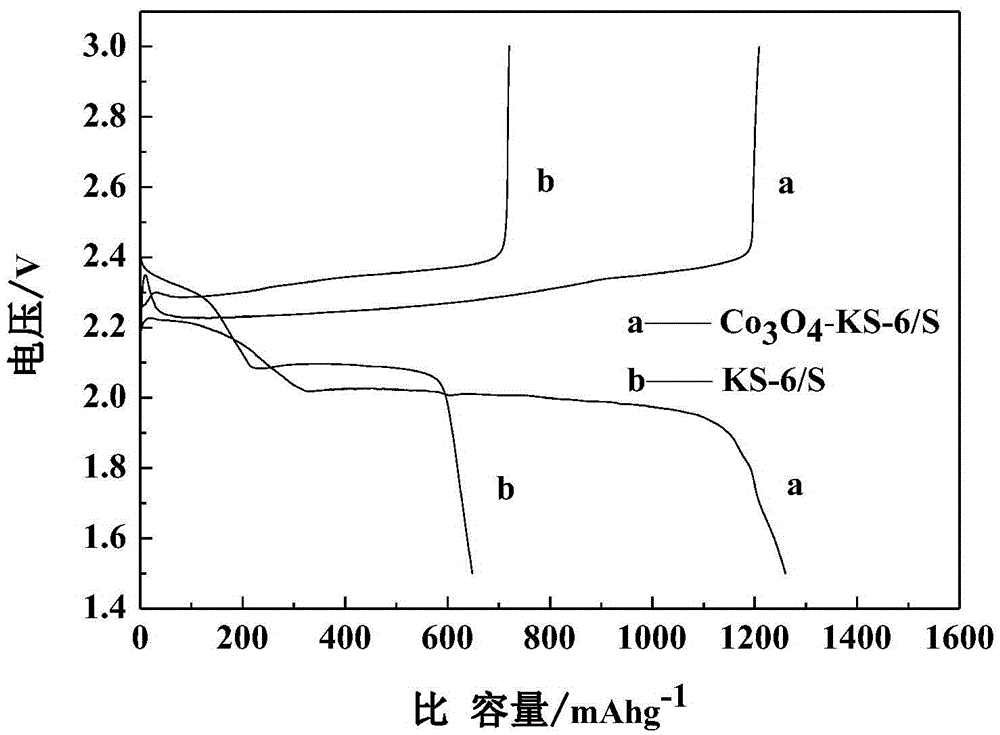

[0037] Based on the above examples, the samples prepared in Examples 1-3 were further used for battery assembly, and the obtained lithium-sulfur battery cathode compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com