Lithium cobalt oxide precursor with coating structure and preparation method and application thereof

A coating structure and precursor technology, which is applied in the field of cathode material precursor preparation, can solve the problems of large amount of lithium cobalt oxide delithiation/intercalation, limited coating effect, failure of coating protection effect, etc., to improve the structure Stability and thermal stability, improvement of cycle performance and safety performance, and the effect of inhibiting the dissolution of metal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

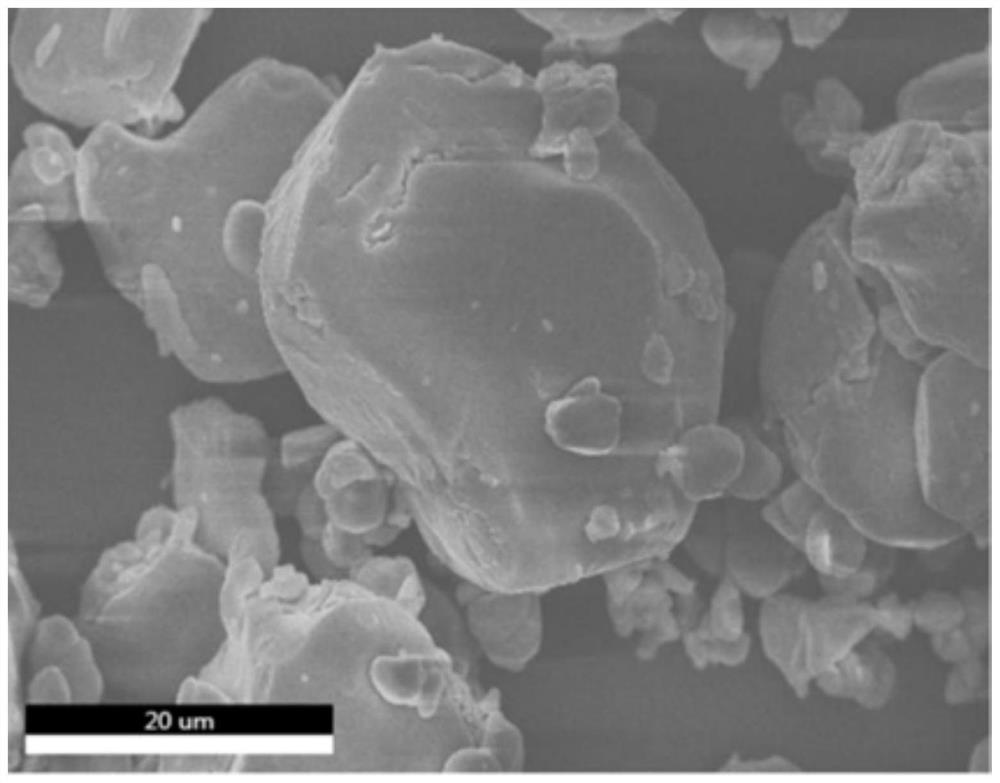

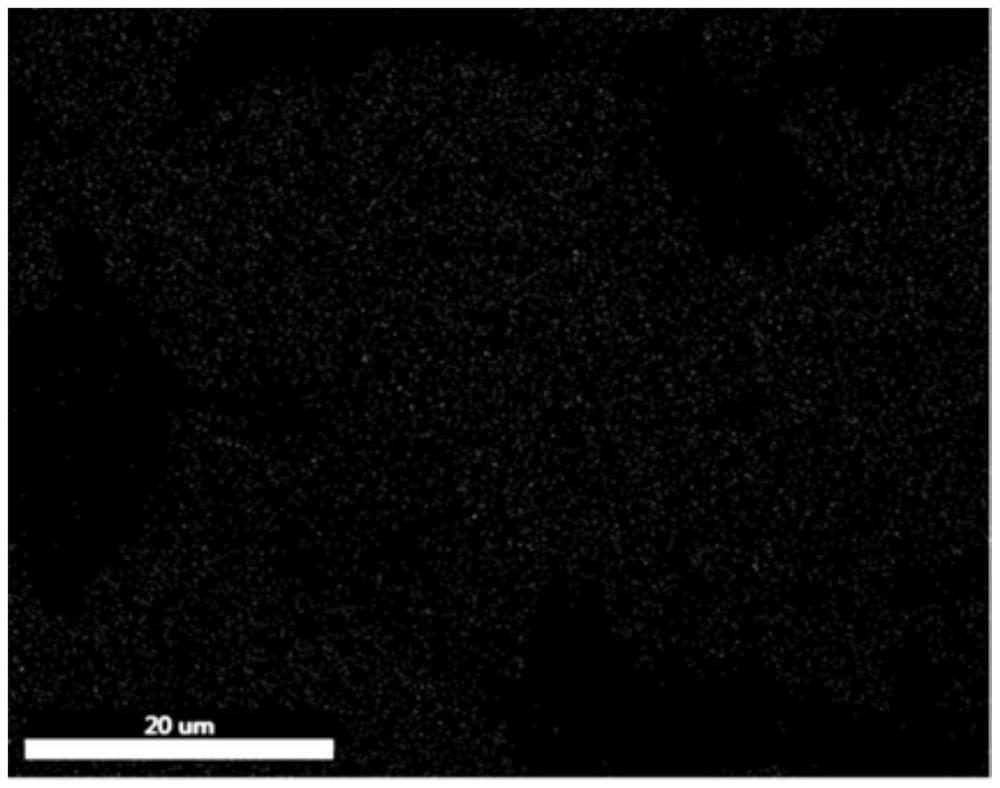

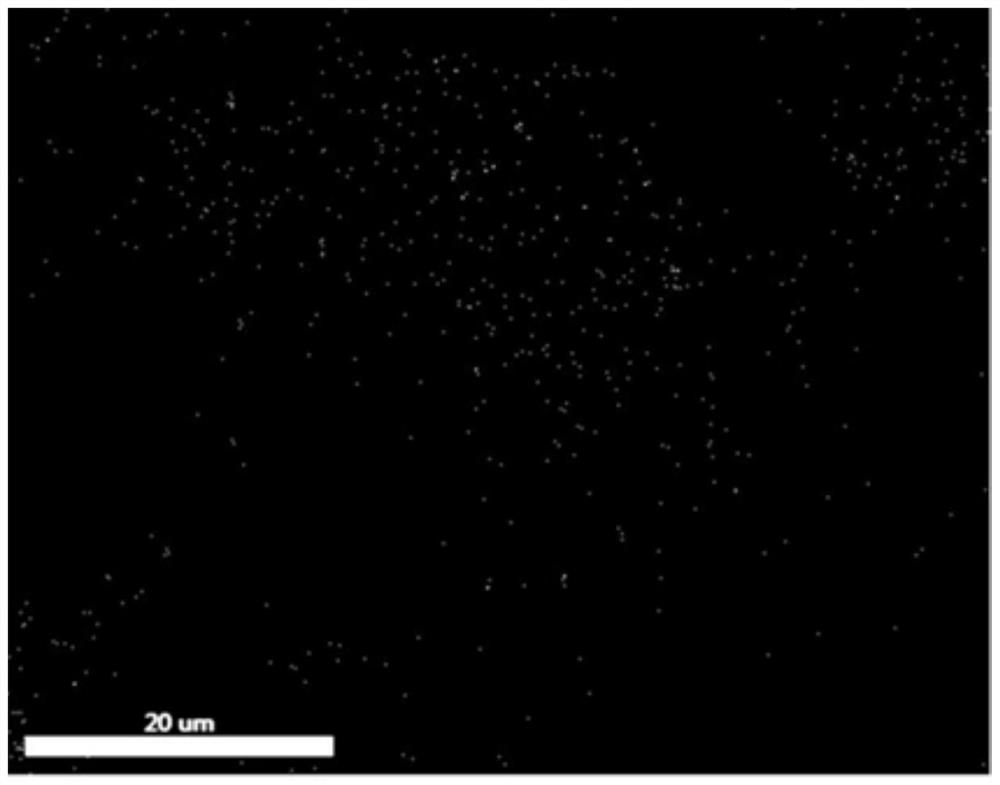

[0068] This embodiment provides a preparation method of a lithium cobalt oxide precursor with a coating structure, and the preparation method specifically includes the following steps:

[0069] (1) Co predoped with Mg, Ti and Al 3 o 4 and deionized water in a beaker with magnetic stirring, Co 3 o 4 The content of pre-doped Mg in the medium is 0.1wt%, the content of Ti is 0.5wt%, and the content of Al is 0.1wt%. After stirring for 3h, add zirconium nitrate aqueous solution drop by drop, every 100g of Co 3 o 4 Add 1.742g of zirconium nitrate, stir for 3h, add ammonia solution dropwise, then continue stirring for 3h to obtain the precursor mixture;

[0070] (2) After the precursor mixture was washed 3 times with deionized water, it was dried at 60°C to obtain a lithium cobalt oxide precursor coated with zirconium hydroxide;

[0071] (3) The lithium cobalt oxide precursor coated with zirconium hydroxide obtained in step (2) was sintered at 500 ° C for 10 h, crushed and ground...

Embodiment 2

[0076] This embodiment provides a preparation method of a lithium cobalt oxide precursor with a coating structure, and the preparation method specifically includes the following steps:

[0077] (1) Co(OH) pre-doped with Mn and Zn 2 and deionized water in a beaker with magnetic stirring, Co(OH) 2 The pre-doped Mn content in the medium is 0.1wt%, and the Zn content is 0.1wt%. After stirring for 3h, add magnesium nitrate aqueous solution drop by drop, every 100g of Co(OH) 2 Add 0.037g of magnesium nitrate, stir for 3h, add ammonia solution dropwise, then continue stirring for 3h to obtain the precursor mixture;

[0078] (2) After the precursor mixture was washed 3 times with deionized water, it was dried at 50°C to obtain a lithium cobaltate precursor coated with magnesium hydroxide on the surface;

[0079] (3) The lithium cobalt oxide precursor coated with magnesium hydroxide obtained in step (2) was sintered at 400 ° C for 12 hours, crushed and ground to obtain a lithium coba...

Embodiment 3

[0083] This embodiment provides a preparation method of a lithium cobalt oxide precursor with a coating structure, and the preparation method specifically includes the following steps:

[0084] (1) Magnetically stir CoO and deionized water pre-doped with Ni and Y in a beaker. The pre-doped Ni content in CoO is 5wt%, and the Y content is 3wt%. After stirring for 3 hours, add zinc nitrate dropwise Aqueous solution, adding 3.655g of zinc nitrate per 100g of CoO, stirring for 3h, adding ammonia solution dropwise, and then continuing to stir for 3h to obtain a precursor mixture;

[0085] (2) After the precursor mixture was washed 3 times with deionized water, it was dried at 55°C to obtain a lithium cobalt oxide precursor coated with zinc hydroxide on the surface;

[0086] (3) The lithium cobalt oxide precursor coated with zinc hydroxide obtained in step (2) was sintered at 450 ° C for 8 h, crushed and ground to obtain a lithium cobalt oxide precursor coated with zinc oxide on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com