Shape memory alloy particular enhanced copper-based composite material and preparation method

A technology of copper-based composite materials and memory alloys, which is applied in the field of shape-memory alloy particle-reinforced copper-based composite materials and its preparation. It can solve the problems of strong interface reaction between magnetic memory alloy particles and the matrix, many holes and defects in composite materials, and long sintering time. , to achieve the effect of short sintering time, low sintering temperature and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

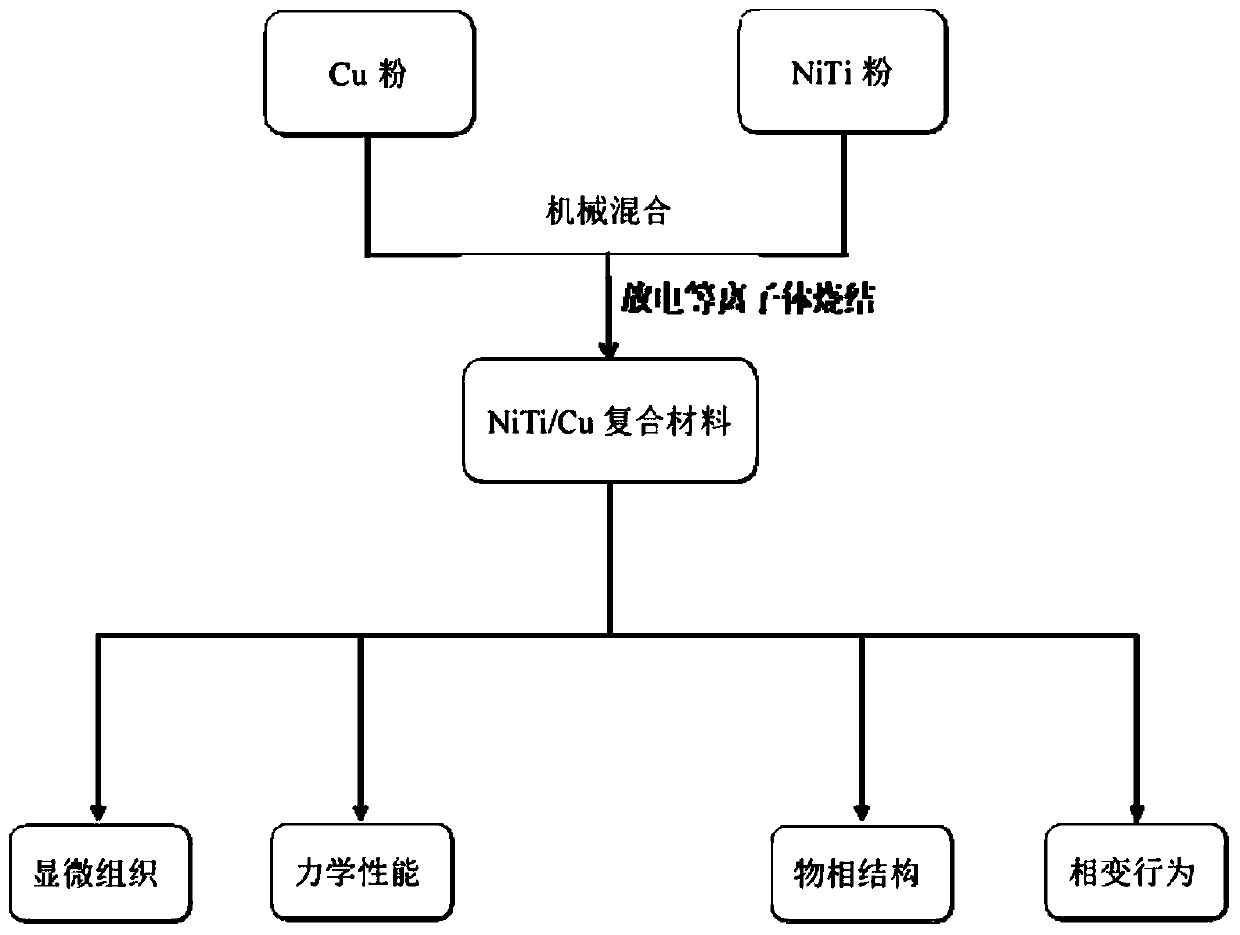

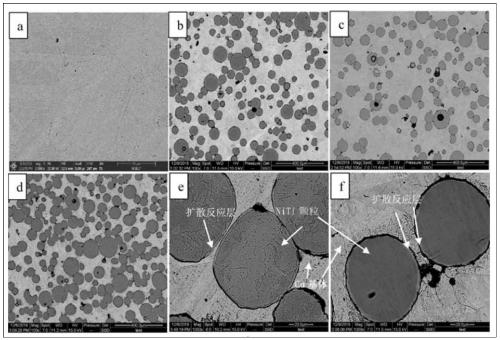

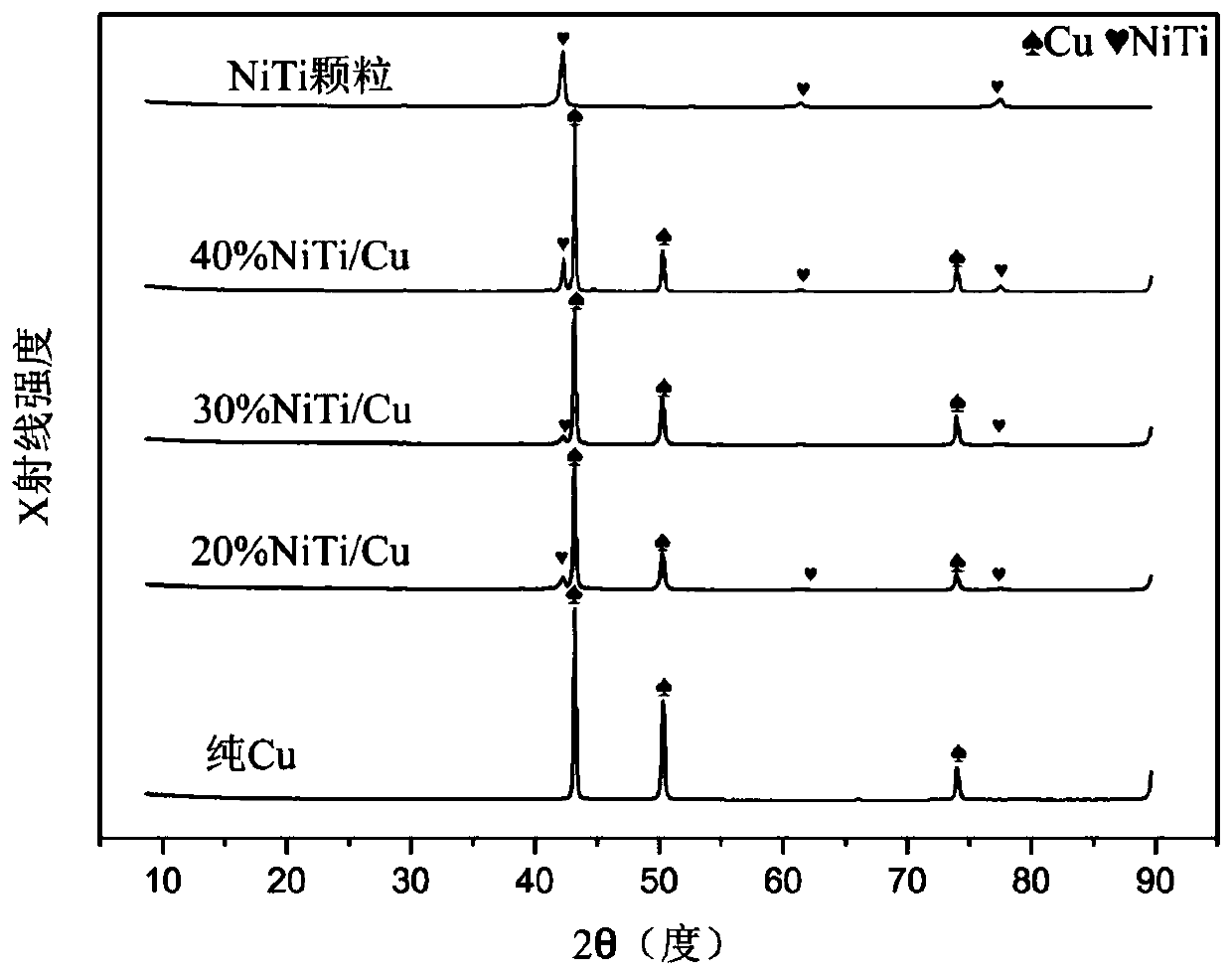

[0031] A copper-based composite material reinforced with shape memory alloy particles and its preparation method, (1) selecting micron-sized (<100 μm) shape memory alloy particles and copper powder particles; (2) selecting the mass fraction of shape memory alloy particles to be 10-60% ; (3) Mechanically mix shape memory alloy particles and copper powder particles for 20-80 minutes; (4) Put the uniformly mixed powder in a graphite mold and sinter at 700-850°C and 40-60MPa by means of discharge plasma sintering 5~10min, obtain shape-memory alloy particle reinforced copper matrix composite; The shape-memory alloy selected in the described step (1) is NiTi alloy; The shape-memory alloy particle and the copper powder particle selected in the described step (1) are mist Formed spherical particles; the preparation process of the composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com