High-speed train-tunnel aerodynamic characteristic movable model experiment system

A technology of air and dynamic characteristics of tunnels, which is applied in aerodynamic tests, machine/structural parts testing, and measuring devices, etc., can solve problems such as inability to launch large train models, decrease in experimental accuracy, and deflection of running tracks, and achieve It is convenient to improve and research, the experimental data is real, and the effect of smoothness is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

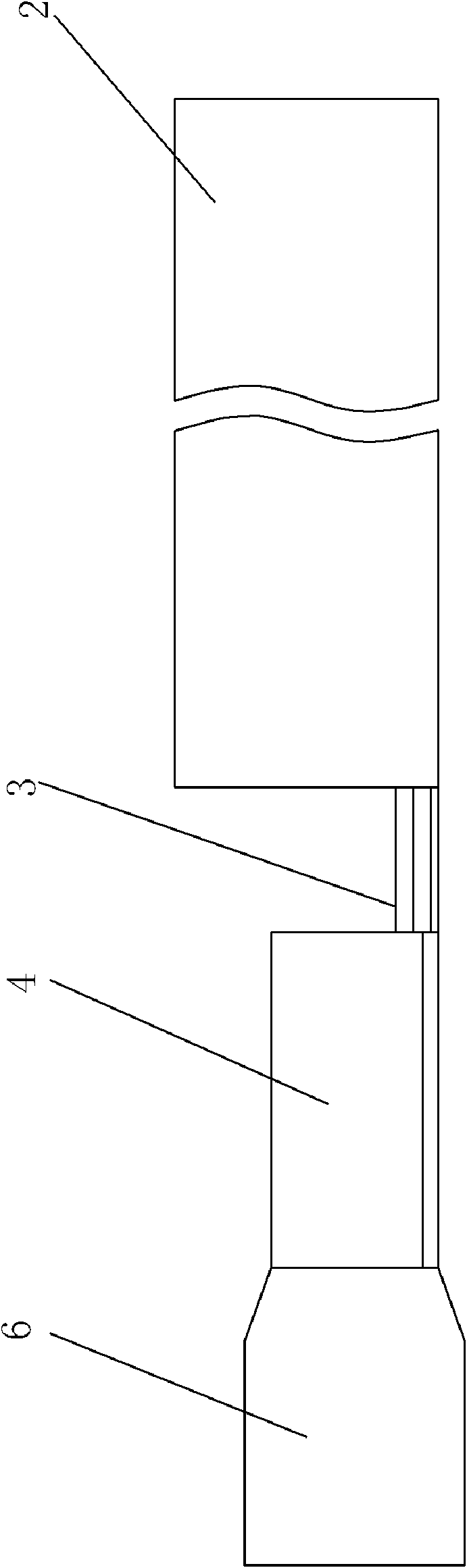

[0022] The implementation of this example is, figure 1 Shown is a high-speed train-tunnel dynamic model test system for aerodynamic characteristics, including an air cannon launching device 6, a train model 1, a tunnel model 2, and a guide rail 3 in the tunnel model 2.

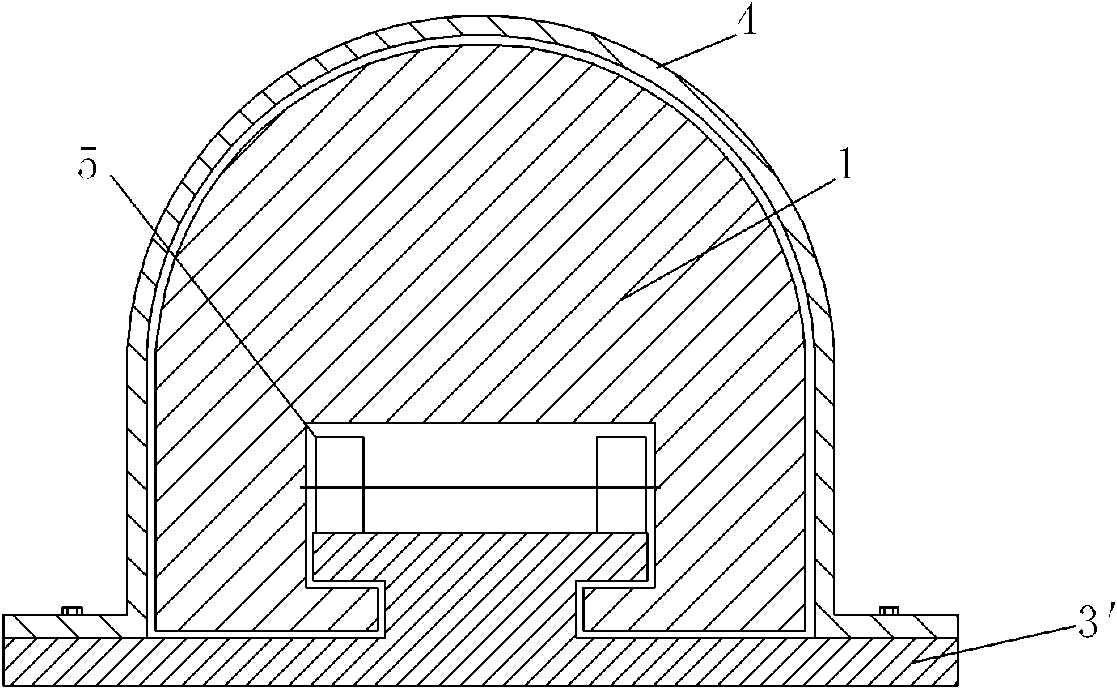

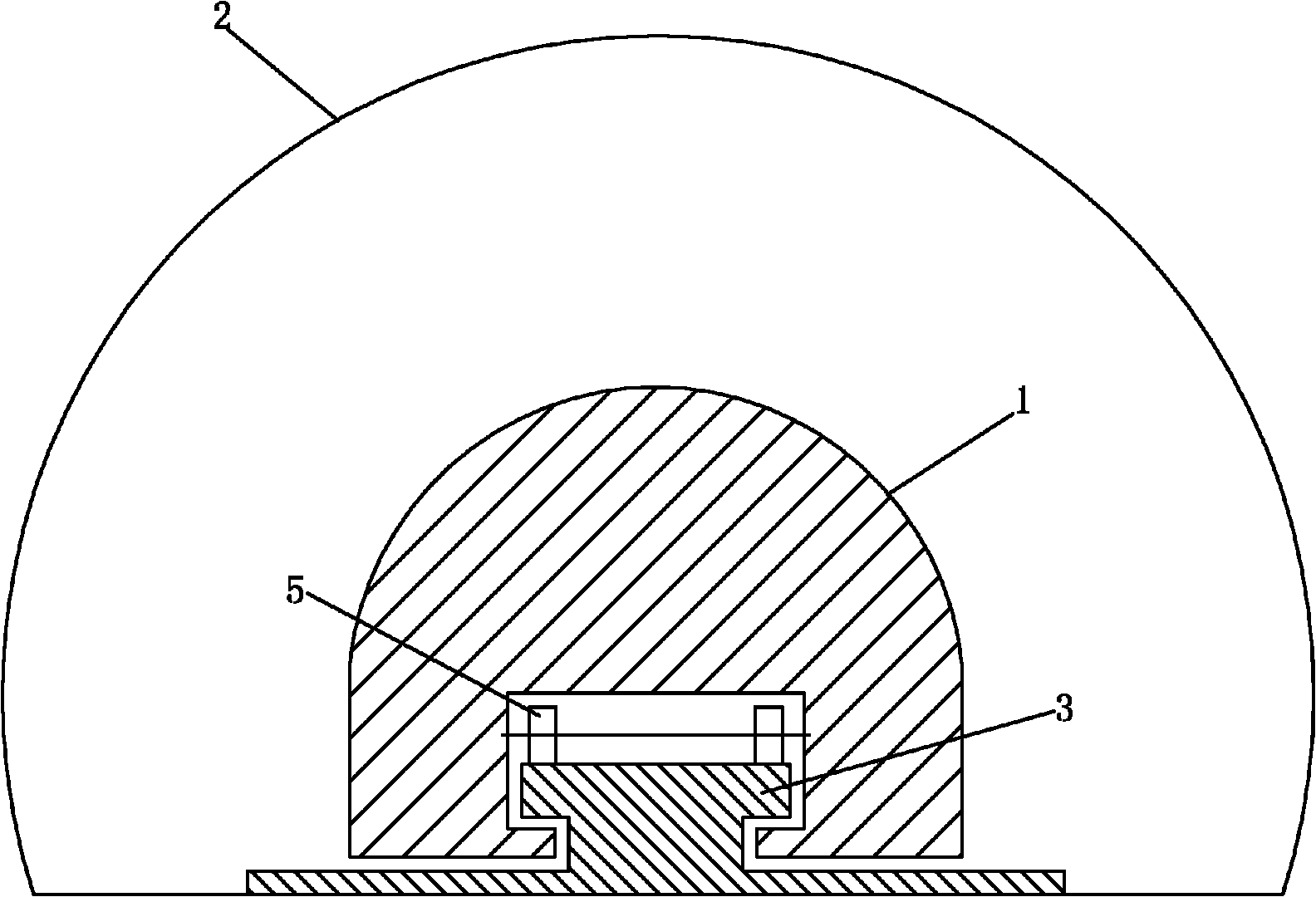

[0023] figure 1 , 2 , 3 show that the section of the gun barrel 4 of the air cannon launching device 6 of this example is "door arch" shape, and its bottom 3 ' shape is the same as the guide rail 3 shape in the tunnel model 2, and is the same as the guide rail in the tunnel model 2. 3 are connected into an integrated structure; the section of the guide rail 3 is an "I"-shaped structure, and the middle of the bottom of the train model 1 matches the "I"-shaped structure of the guide rail 3, and the train model 1 is slidably fitted on the guide rail 3.

[0024] figure 2 It is also shown that a wheel 5 is installed between the upper surface of the "I"-shaped structure of the guide rail 3 of this example and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com