Air bag type floating loading mechanism

A loading mechanism and airbag-type technology, which is applied in the field of airbag-type floating loading mechanism, can solve the problems of unpublished bridge durability wheel load test device loading mechanism, etc., and achieve the effect of reducing self-weight, reducing running resistance, and authentic experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

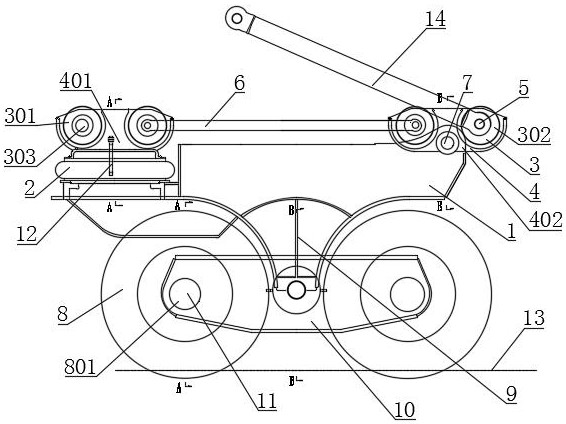

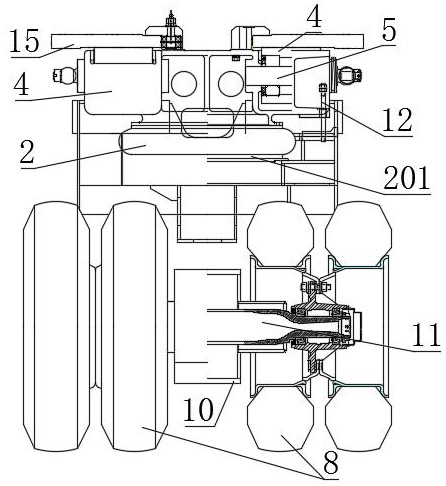

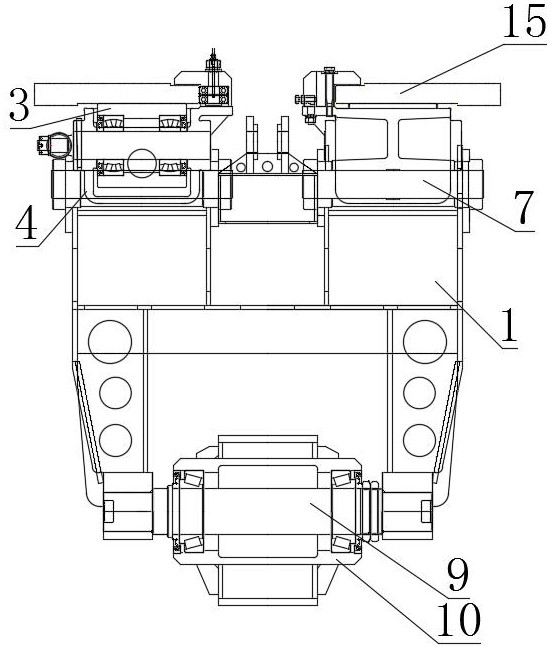

[0033] The upper end of the airbag 2 is sealed and fixed at the bottom of the first loading wheel box seat 401. The left and right ends of the first loading wheel box seat 401 are each supported by two pins through bearings to support the four first loading wheels 301. The lower end of the airbag 2 is connected to the airbag bottom plate. 201 is sealed and seated on the loading body 1. The left and right ends of the first loading wheel box seat 402 are also supported by two pin shafts through bearings, respectively, and the two second loading wheels 302 are supported. The first loading wheel box seat 402 is hinged to the upper surface of the loading body 1 through the shaft pin sensor 7 101; One end of the bridge deck reaction force of the loading body 1 is applied by the rolling wheel 8, the suspension, the loading body 1, the airbag bottom plate 201, the airbag 2, the first loading wheel box seat 401, the pin shaft, the bearing, and the first loading wheel 301 On the track, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com