Test coating machine for sensitive material

A photosensitive material and experimental technology, which is applied to devices and coatings for coating liquid on the surface, which can solve the problems of inability to carry out comprehensive experimental testing, inability to approach the production mode, and single function, so as to omit the experience conversion link, Broaden the scope of the experiment, the real effect of the experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

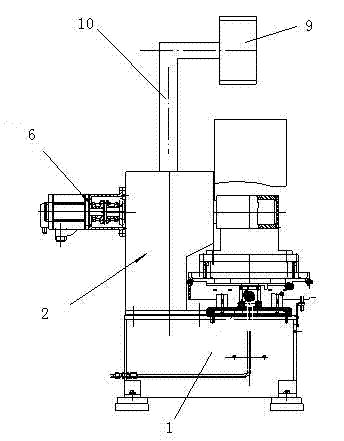

[0029] Such as image 3 As shown, the fuselage is composed of a horizontal frame body 1 and a vertical frame body 2, and the fuselage is made of carbon steel welded parts, which are subjected to aging treatment to eliminate internal stress, and then processed by machining. The bottom of the horizontal frame is equipped with 7 shock absorbing pads, and the machine level can be adjusted at the same time.

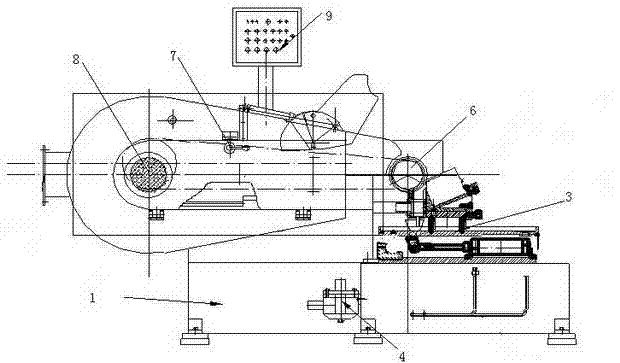

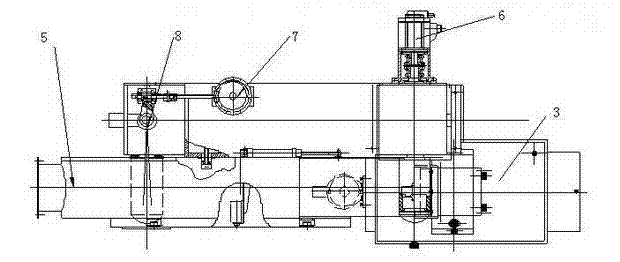

[0030] Such as Figure 1~3 As shown, the horizontal frame is sequentially provided with a coating operation table 3, a vacuum negative pressure system 4 and a horizontal condensation box 5; The roller tensioning mechanism 8, the infrared photoelectric switch detected by the ring joint is adjacent to the main drive roller device; the fixed frame 10 with the electrical control system 9 connected to the top of the vertical frame body; the infrared photoelectric switch d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com