Breeches pipe arrangement method in arrangement of high-lift lock unilateral lock wall main corridor

A high-head, fork-pipe technology, applied in ship locks, ship lifting devices, climate change adaptation, etc., can solve problems such as affecting the stability of the fork-pipe structure, affecting the layout of energy dissipation facilities, and affecting the berthing conditions of the lock chamber, so as to improve engineering safety. The effect of high stability, low construction difficulty and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

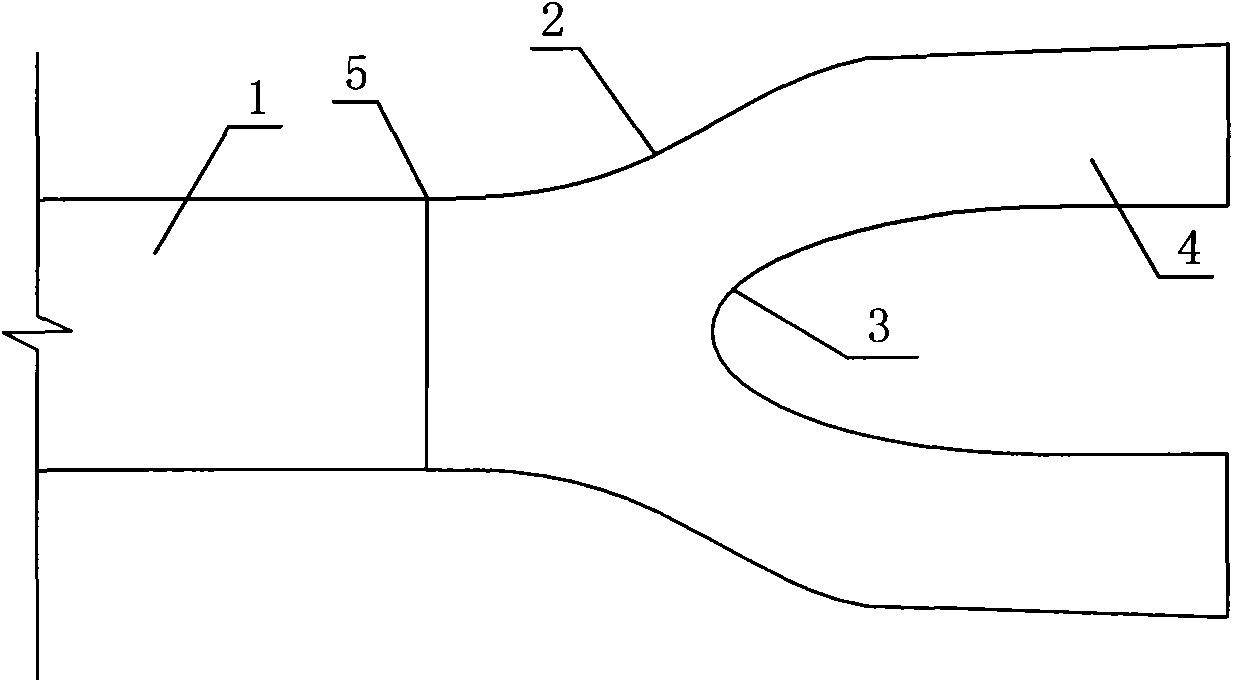

[0019] The arrangement of the present invention is as figure 1 As shown, a fork pipe arrangement form under the main corridor layout of the single-side lock wall of a high-head ship lock, at the entrance (distributor) of the fork pipe, the side wall curve 2 of the fork pipe is tangent to the main corridor 1, and tangent to At point 5, the curve 2 of the side wall of the fork pipe is streamlined; the end of the diversion pier 3 of the fork pipe is tangent to the wall 4 of the branch pipe, and the curve of the diversion pier 3 of the fork pipe is elliptical.

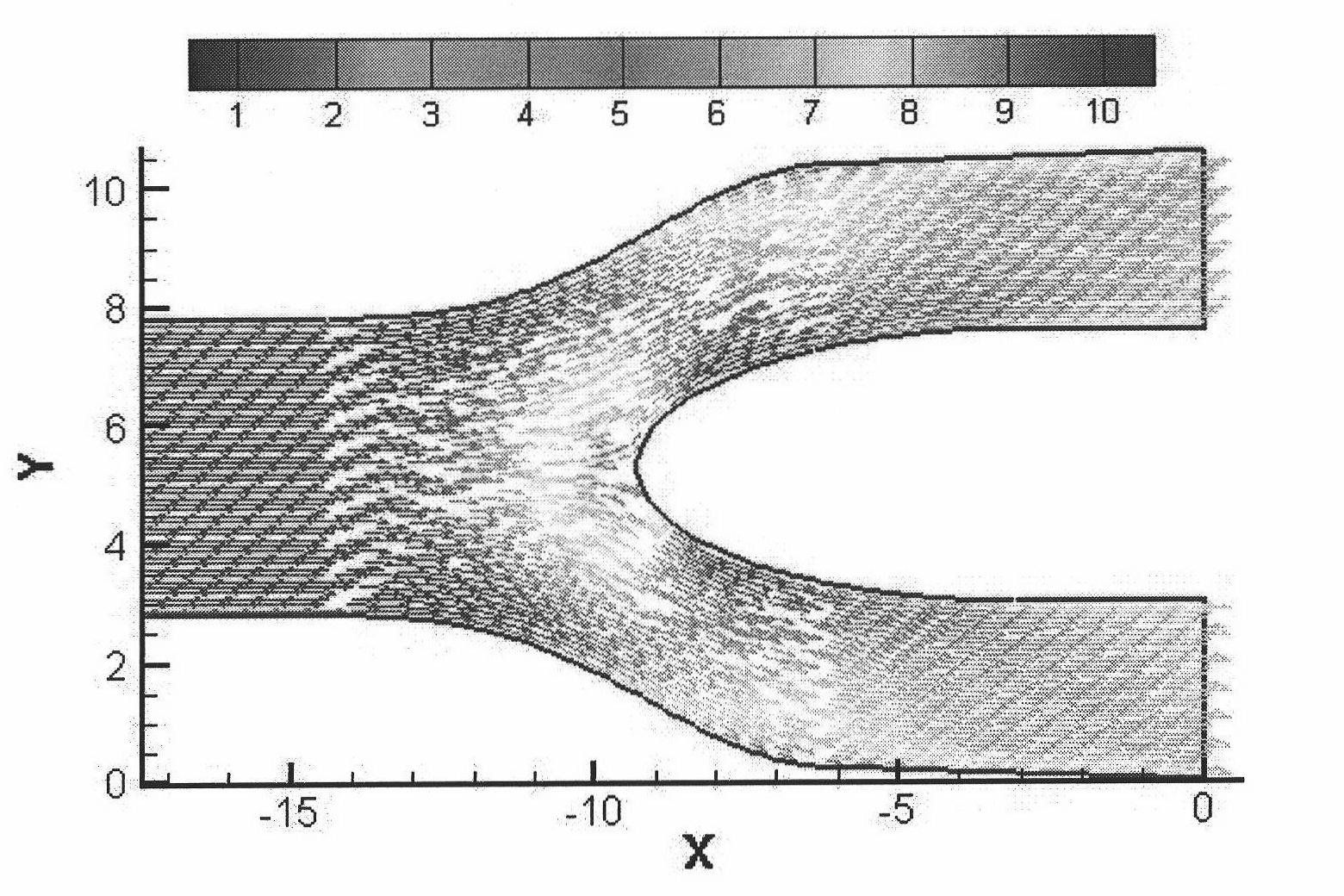

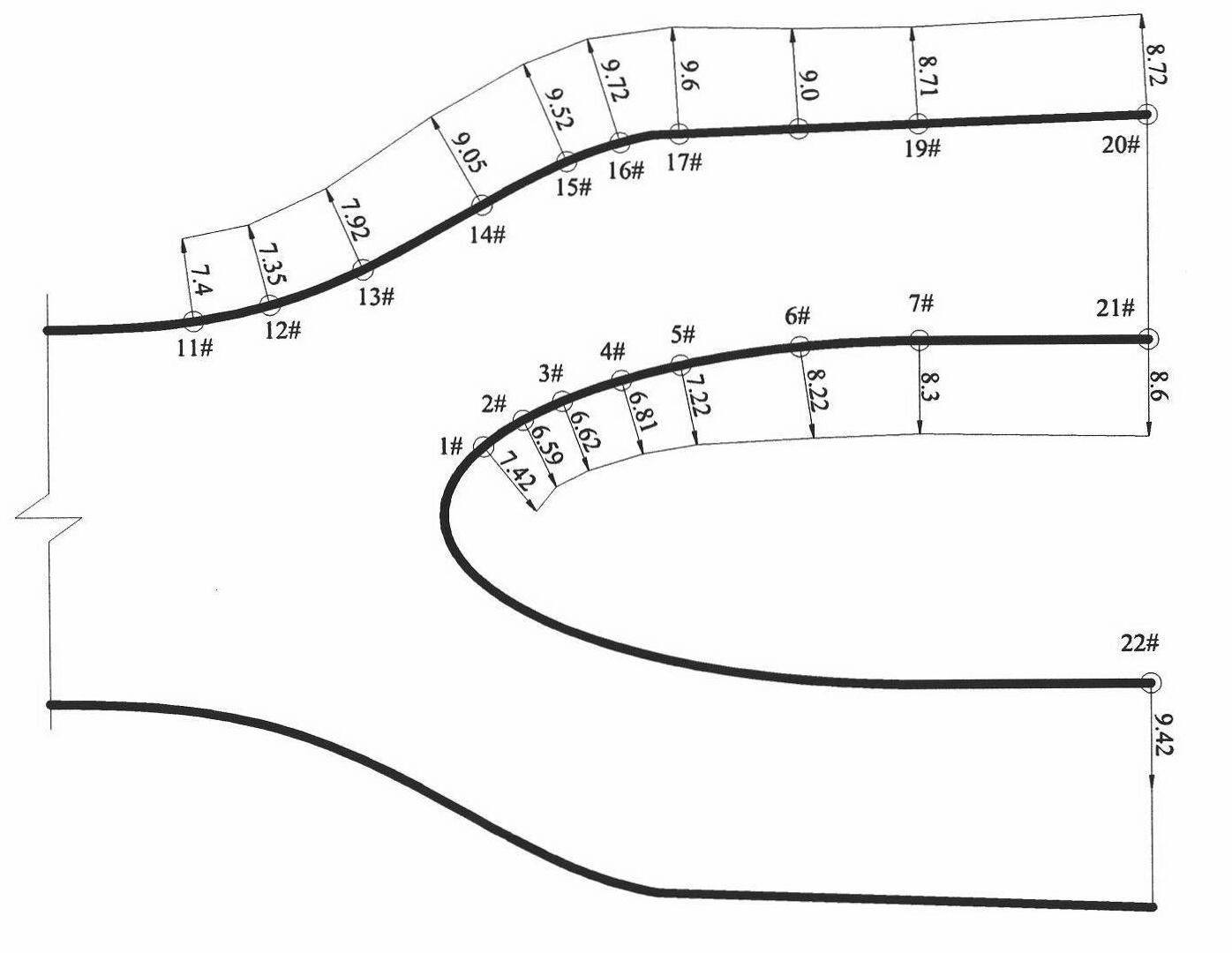

[0020] figure 2 , image 3 and Figure 4 It is the flow field in the pipe and its pipe wall pressure distribution diagram (both sides operation) of the present invention. Figure 5 , Figure 6 and Figure 7 It is the flow field in the pipe and its pipe wall pressure distribution diagram (bilateral operation) of the present invention.

[0021] image 3 , Figure 4 , Figure 6 , Figure 7 The time-average pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com