Joint between housing and headlamp outer lens with glue-retaining ribs

A technology of ribs and outer lenses, applied in the field of lighting devices, can solve problems such as excessive accumulation, and achieve the effect of forming a cheap and simple solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

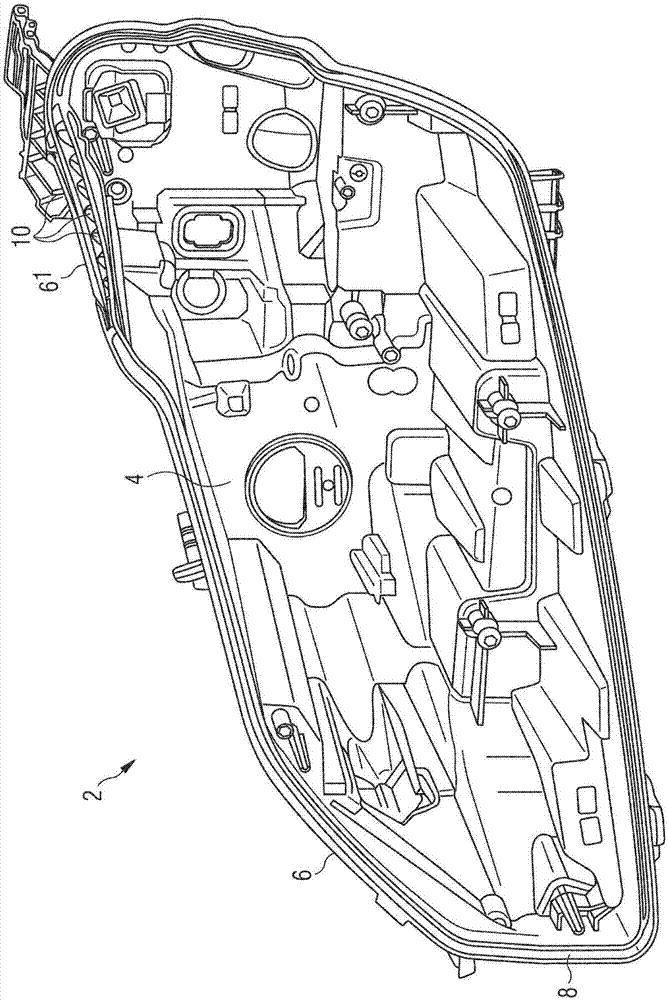

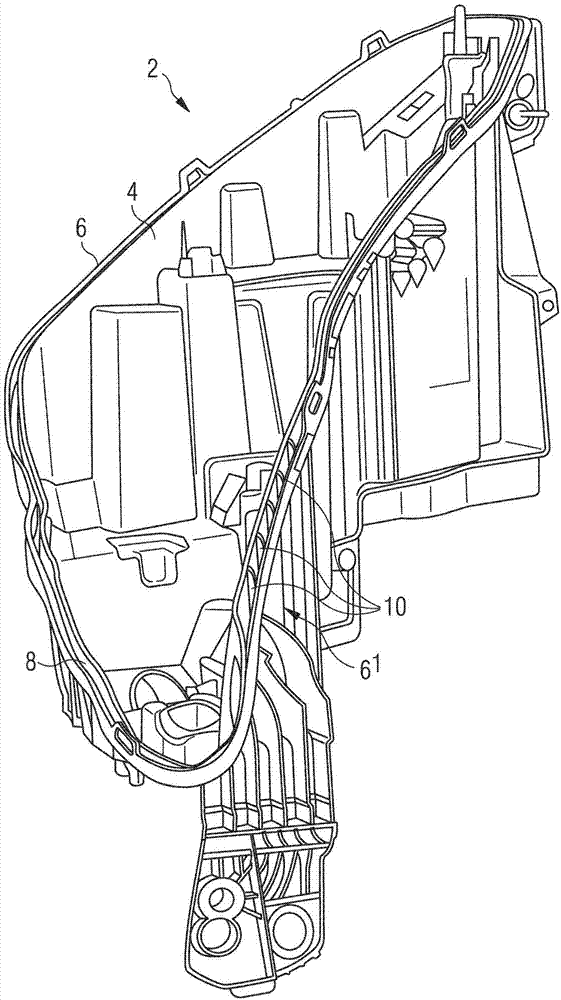

[0045] figure 1 A housing 2 for a lighting device, in this case a motor vehicle headlight, is shown. Such lighting devices can perform different functions, in particular low-beam or high-beam lighting, or signaling functions, such as direction indicators (blinkers), side lights or daytime running lights (DRL).

[0046] The housing 2 comprises a wall 4 which may have a complex shape. Said wall 4 forms a cavity designed to receive one or more lighting modules (not shown) designed to perform one or more of the aforementioned functions. These modules are well known to those skilled in the art.

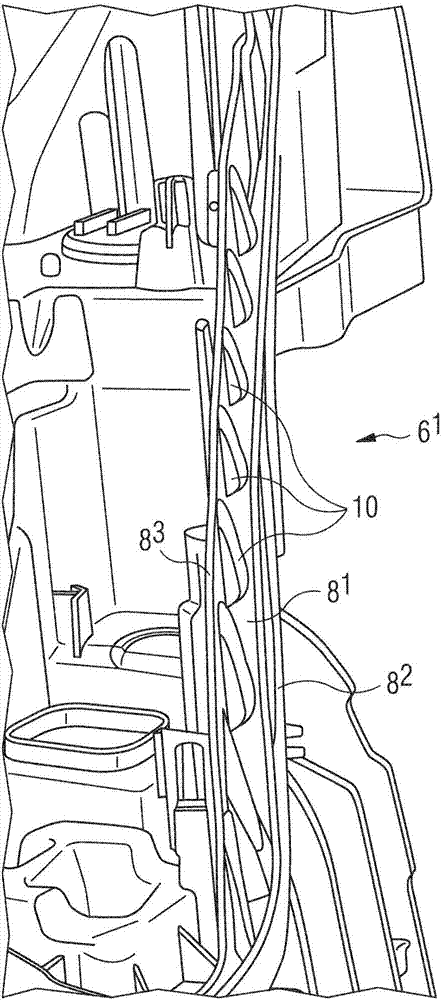

[0047]The housing 2 also comprises a rim 6 delimiting the opening of the cavity. This edge is advantageously located on the wall 4 and, more specifically, at the end of said wall. The edge 8 advantageously forms a closed contour delimiting the opening of the cavity of the housing. Said edge 6 is designed to cooperate with the outer lens in order to close the cavity. The outer lens is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com