Test mold for testing limit oxygen index of asphalt and test method thereof

A technology for limiting oxygen index and testing, applied in the preparation of test samples, chemical analysis by combustion, sampling, etc., can solve problems such as inability to obtain accurate limit oxygen index, inability to obtain limit oxygen index, and inability to maintain an upright state , to achieve the effect of convenient maintenance and cleaning of the instrument, shortening the test time, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

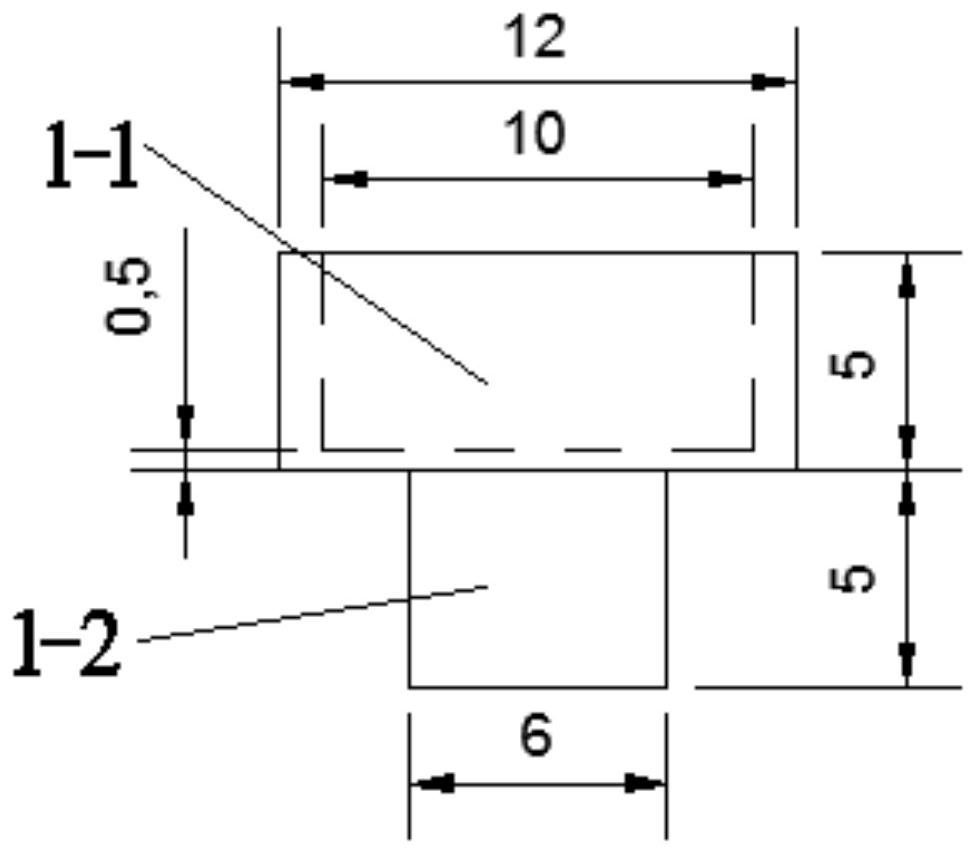

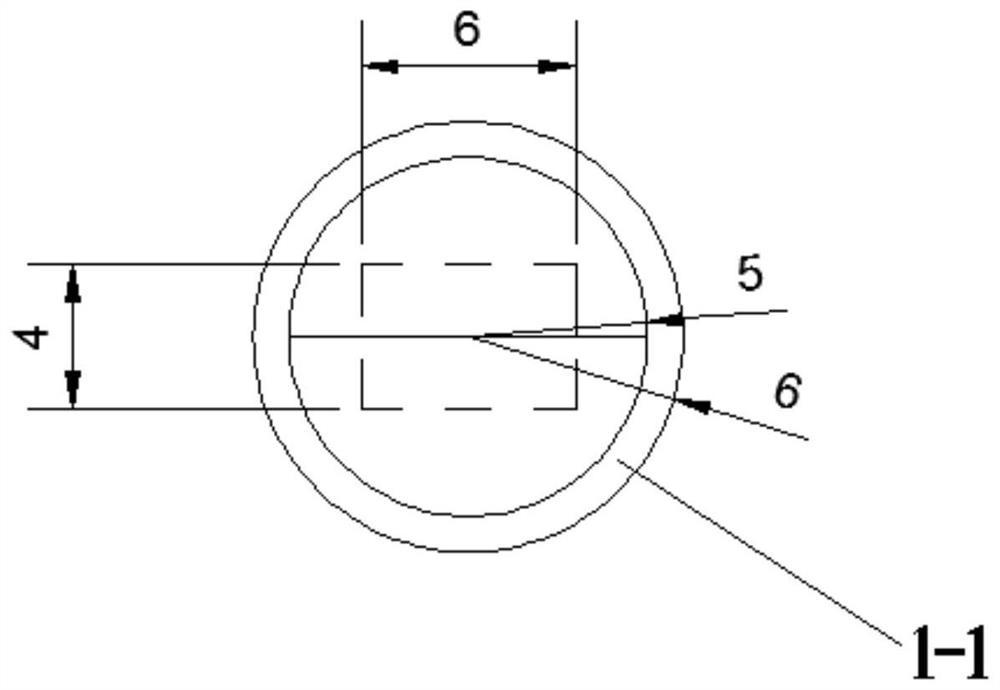

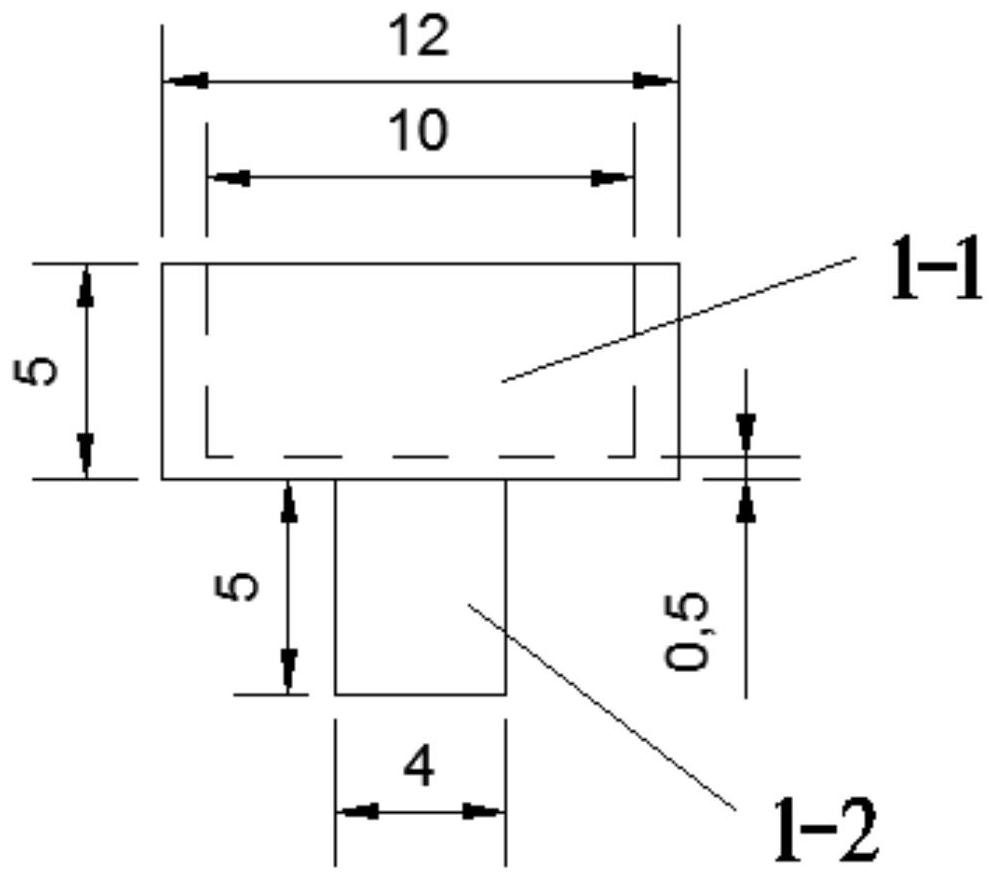

[0041] Such as Figure 1 ~ Figure 3As shown, the trial mold 1 of the present invention includes a steel cup 1-1 and a fixing member 1-2 vertically fixedly connected to the outside of the bottom of the steel cup 1-1.

[0042] In this embodiment, the test mold 1 includes a steel cup 1-1 and a fixture 1-2 vertically fixedly connected to the outside of the bottom of the steel cup 1-1. In actual use, the steel cup 1-1 carries the asphalt 3, so that The asphalt 3 is placed in the steel cup 1-1, which avoids the occurrence of asphalt 3 flowing, solves the problem of flowing asphalt 3 directly in the limit oxygen index test, and protects the fixtures and test instruments from asphalt during the test 3. It is convenient to maintain and clean the instrument, ensuring the accuracy of the obtained limiting oxygen index data, and at the same time improving the limiting oxygen index standard in the limiting oxygen index test. By setting the fixing part 1-2 perpendicular to the steel cup 1-1...

Embodiment 2

[0048] This embodiment includes the following steps:

[0049] Step 1. Prepare the sample: put the SBS modified asphalt in an oven and keep it warm until it flows, then pour it into the steel cup 1-1 of the test mold 1 after stirring, and then insert the glass fiber 3-1 vertically into the asphalt 3 , and cooled to room temperature to obtain a test mold 1 equipped with asphalt 3; the temperature in the oven is 120°C, the cooling time is 3h, and the length of the glass fiber 3-1 is the length of the inside of the steel cup 1-1 110% of height;

[0050] Step 2, install the sample: install the test mold 1 equipped with asphalt 3 obtained in step 1 on the sample holder 2 of the combustion cylinder of the oxygen index meter to obtain the assembled combustion cylinder; The distance between test mold 1 and the upper and lower ends of the combustion cylinder is more than 10cm; the oxygen index tester is JF-3 type oxygen index tester;

[0051] Step 3, setting the volume concentration o...

Embodiment 3

[0065] This embodiment includes the following steps:

[0066] Step 1. Prepare the sample: put the SBS modified asphalt mixed with Sasobit warm mix agent into an oven and keep it in a fluid state, then pour it into the steel cup 1-1 of the test mold 1 after stirring, and then add the glass fiber 3 -1 is vertically inserted into the asphalt 3, cooled to room temperature to obtain a test mold 1 equipped with asphalt 3; the temperature in the oven is 100°C, and the cooling time is 2h; the length of the glass fiber 3-1 105% of the internal height of steel cup 1-1;

[0067] Step 2, install the sample: install the test mold 1 equipped with asphalt 3 obtained in step 1 on the sample holder 2 of the combustion cylinder of the oxygen index meter to obtain the assembled combustion cylinder; The distance between test mold 1 and the upper and lower ends of the combustion cylinder is more than 10cm; the oxygen index tester is JF-3 type oxygen index tester;

[0068] Step 3, setting the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com