Axial actuating device with elastic coupling part

An actuating device, axial technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of long axial length, no shock resistance, large space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

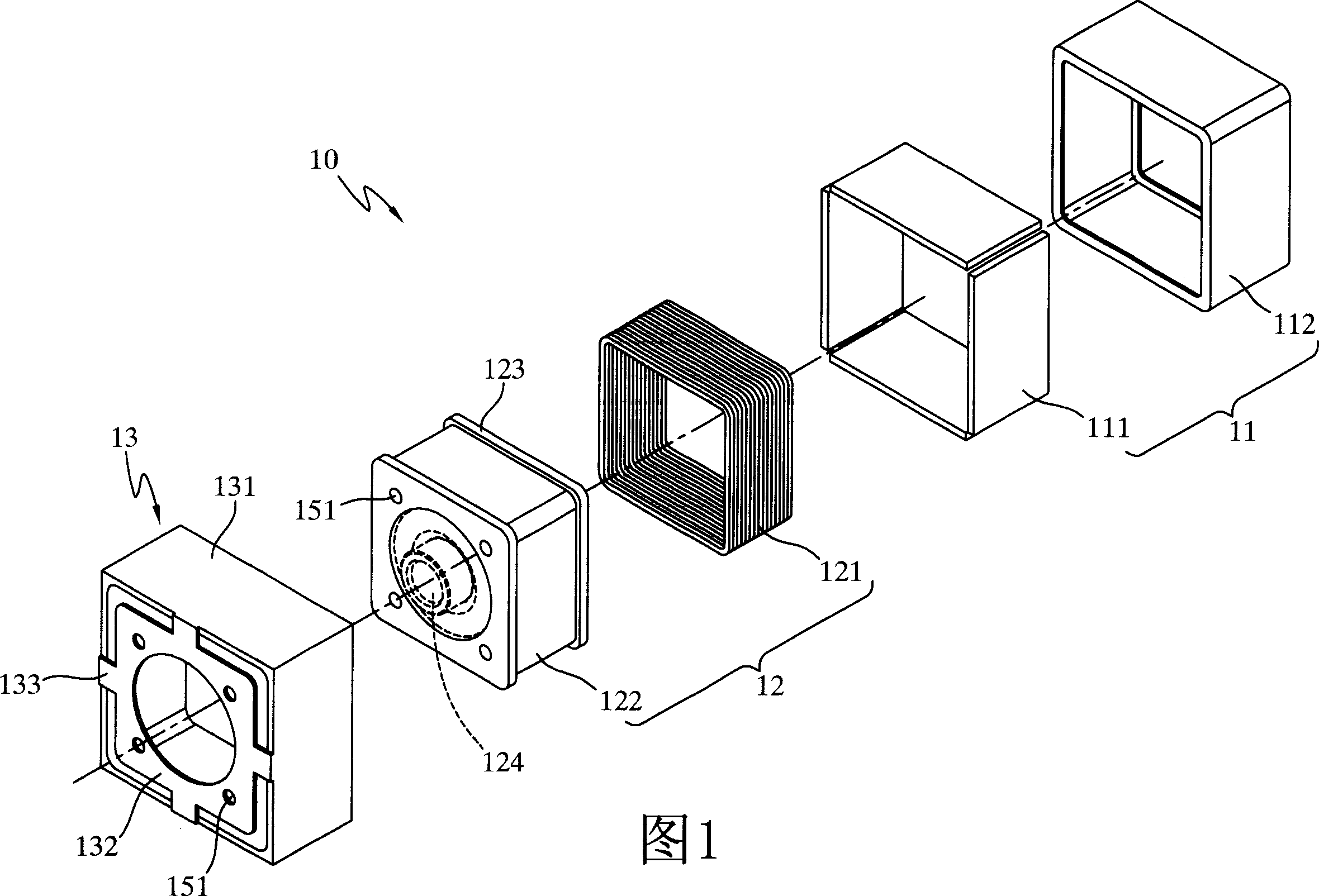

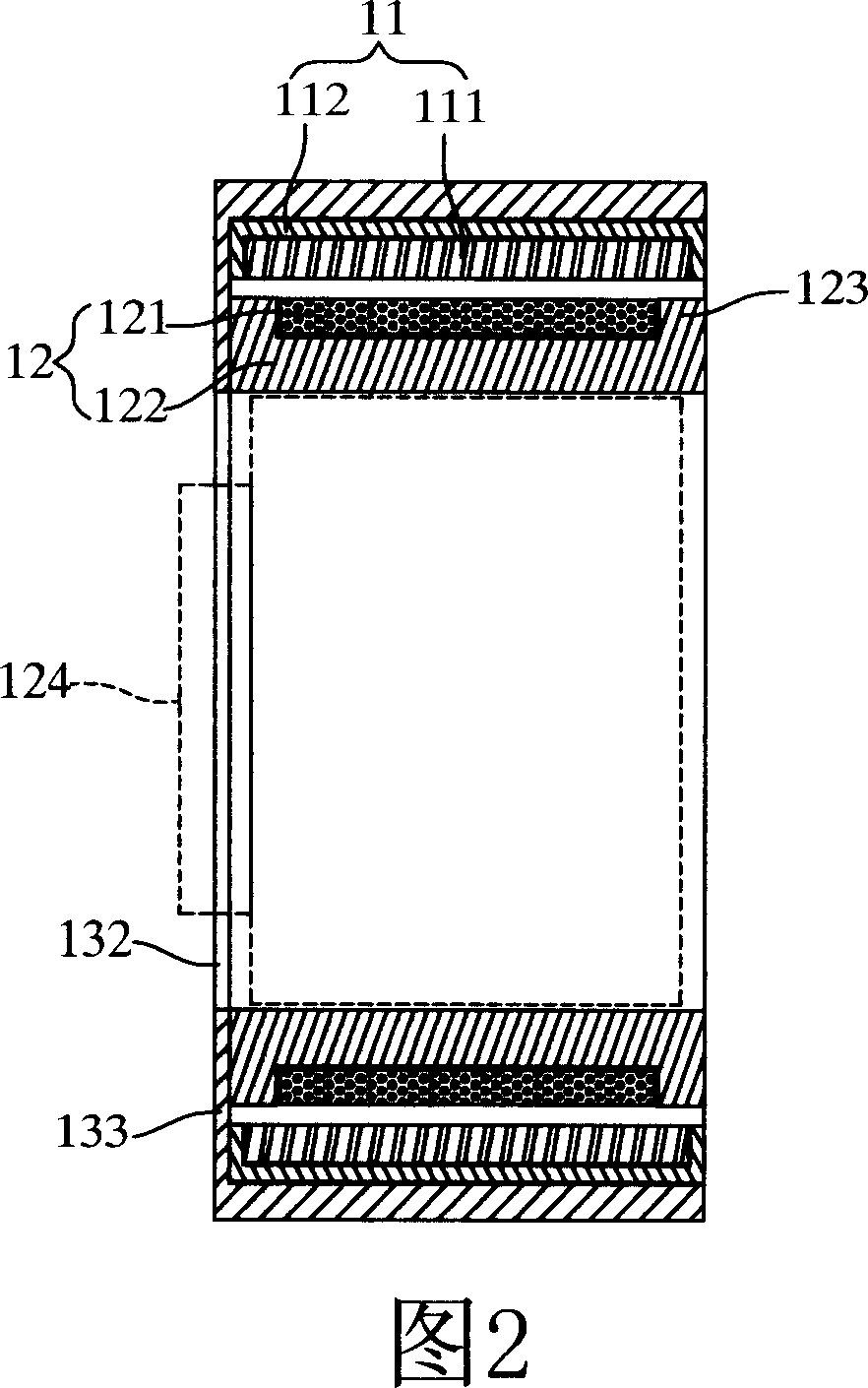

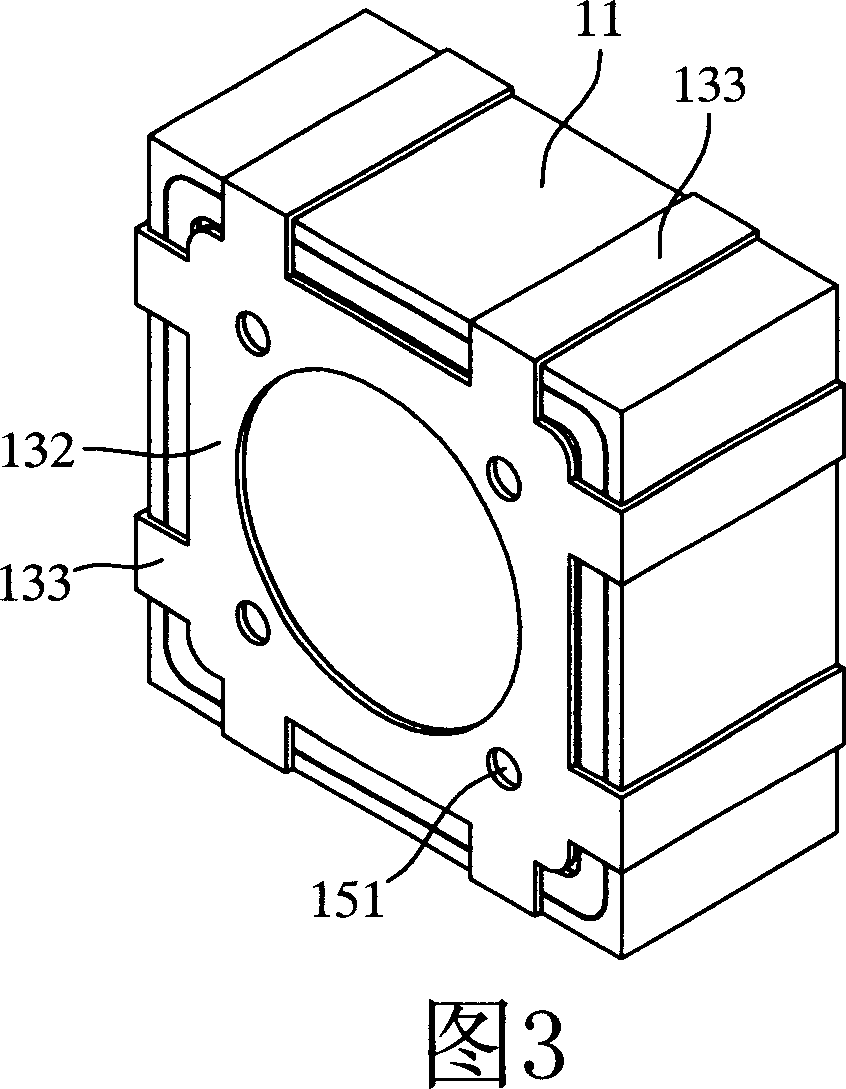

[0032] As shown in FIG. 1 , it is a three-dimensional exploded embodiment diagram of an axial actuating device 10 with an elastic coupling portion of the present invention. As shown in FIG. 2 , it is a combined cross-sectional embodiment diagram of an axial actuating device 10 with an elastic coupling part of the present invention. FIG. 3 is a three-dimensional embodiment view of an axial actuating device with an elastic coupling part of the present invention with the support member omitted. As shown in FIG. 4 , it is a cross-sectional embodiment diagram of an axial actuating device 10 with an elastic coupling part of the present invention, the movable part 12 of which is in a stretched state. As shown in FIG. 5 , it is another implementation state diagram of the coupling part 13 of an axial actuator device 10 with an elastic coupling part according to the present invention. As shown in FIG. 6 , it is a graph showing the relationship between current and displacement of an axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com