Switch valve with temperature adjusting function

A technology for temperature regulation and on-off valves, which is applied to valve details, diaphragm valves, multi-way valves, etc., and can solve problems that affect the normal use of on-off valves, poor sealing effects, and easy deflection of the linkage rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

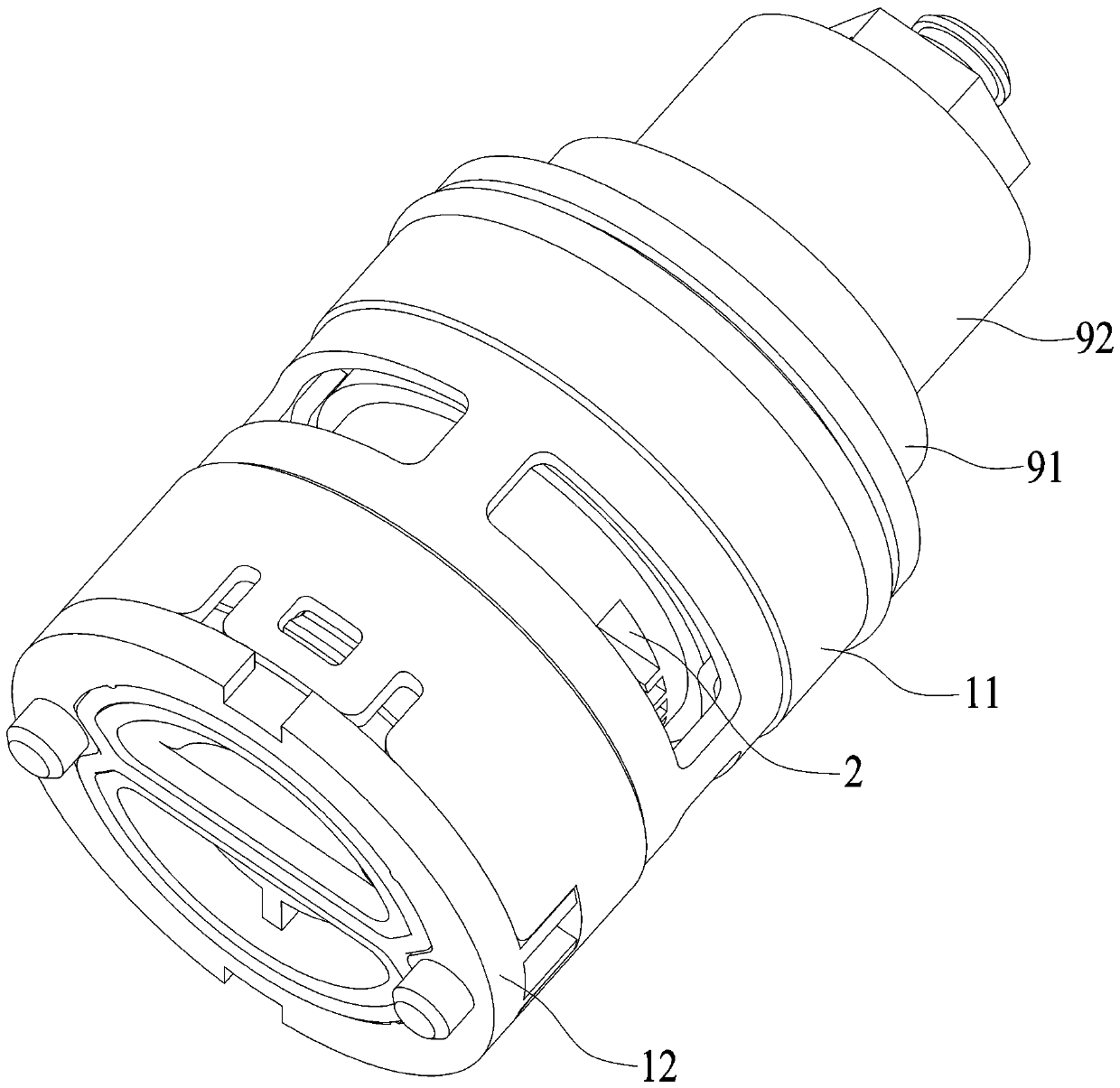

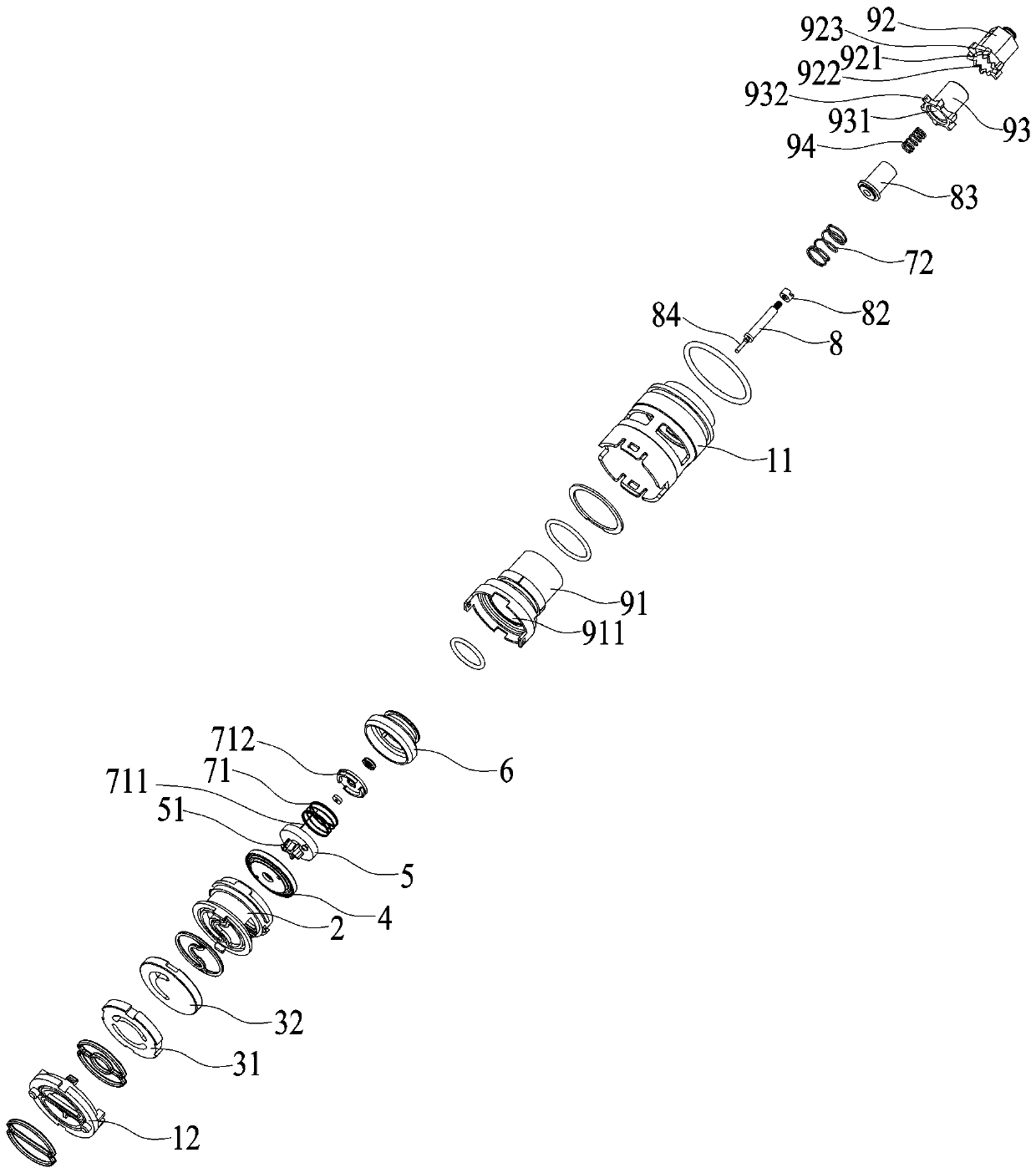

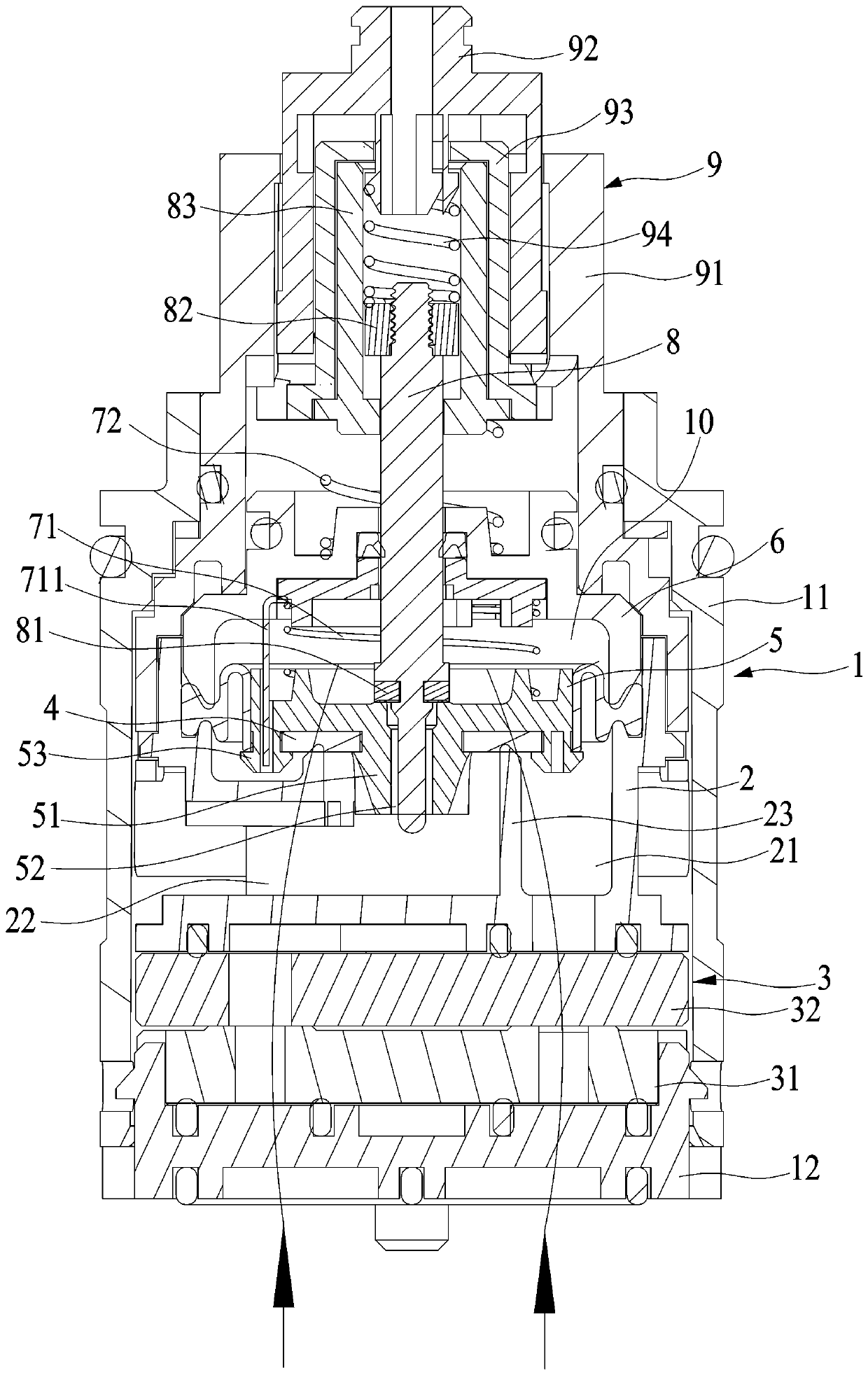

[0073] see Figure 1 to Figure 13 As stated above, the on-off valve with temperature adjustment disclosed by the present invention includes a valve seat 1, a valve core body 2, a temperature adjustment assembly 3, a sealing diaphragm 4, a diaphragm support 5, a pressure-bearing inner cover 6, a first spring 71, The second spring 72 , the sealing guide rod 8 and the pressing structure 9 .

[0074] The valve core body 2 is rotatably installed in the valve seat 1. Generally, the valve core body 2 is rotatably sleeved in the valve seat 1. In this embodiment, the valve seat 1 includes a valve sleeve 11 and a valve core base 12. The valve sleeve 11 Fastening is installed on the spool base 12. A water inlet channel 21 and a water outlet channel 22 are formed in the spool body 2, such as image 3 , Figure 4 and Figures 11a to 11c As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com