Eucalyptus vane plywood and manufacturing method thereof

A fan blade and eucalyptus wood technology, which is applied in the field of eucalyptus plywood fan blades and its manufacturing, can solve the problems of insufficient rigidity, deflection, and layer drop, and achieve good mechanical processing performance, high tensile strength, and elastic modulus. A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

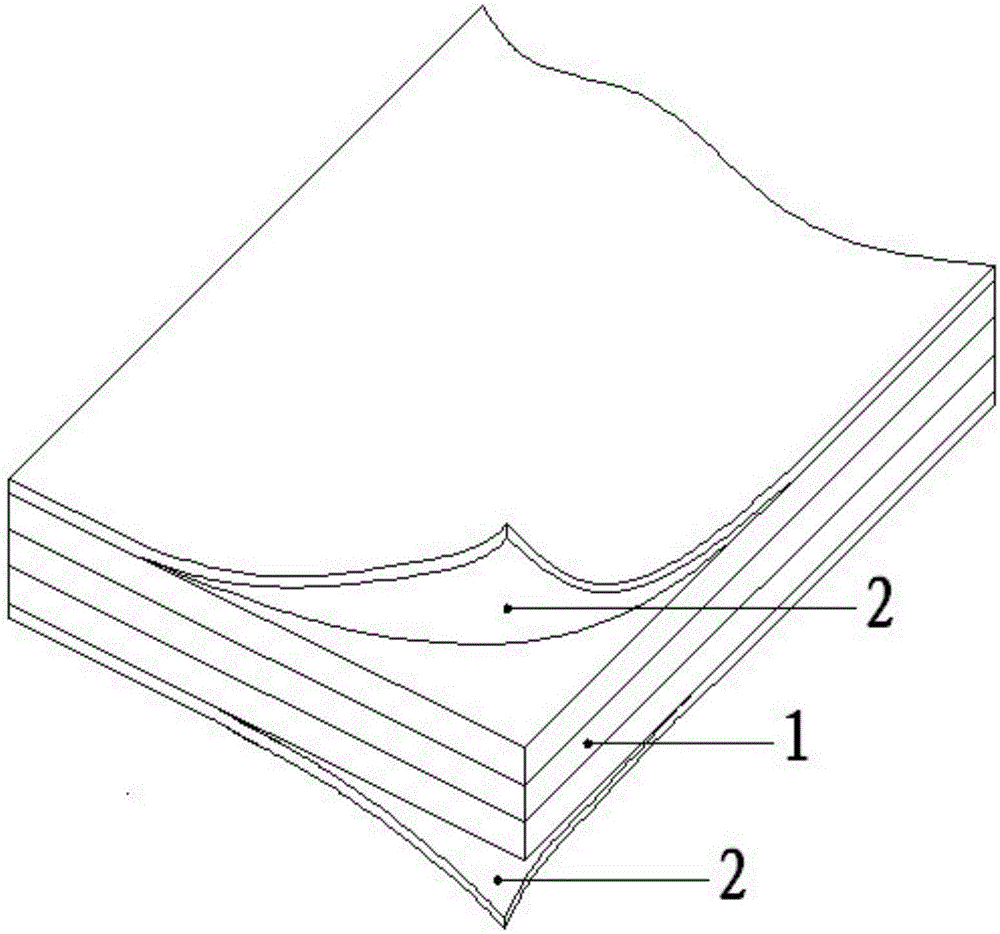

[0029] Such as figure 1 As shown, a eucalyptus plywood fan blade board includes a core board 1 and panels 2 glued on both sides of the core board 1. The core board 1 is composed of three veneers, and two veneers are coated with Core board adhesive; described veneer adopts the eucalyptus veneer that is formed by rotary cutting of eucalyptus logs; described core board adhesive is made of the components of following ratio: E0 urea-formaldehyde resin glue: flour: chlorine Ammonium chloride: iron red powder=1:0.4:0.006:0.001; the described panel 2 adopts the ice candy wood panel formed by rotary cutting of ice candy wood; The above-mentioned panel adhesive is made of the following components: E0 urea-formaldehyde resin glue:flour=1:0.5. The E0 urea-formaldehyde resin in the core board adhesive and the panel adhesive is made of the following components: formaldehyde: urea: melamine: accelerator Z-1: polyvinyl alcohol 20-99=1:0.725 :0.025:0.020:0.025.

[0030] The thickness of the...

Embodiment 2

[0032] A eucalyptus glued fan blade board, comprising a core board 1 and panels 2 glued on both sides of the core board 1, the core board 1 is composed of three veneers, and core board glue is coated between two veneers Sticky agent; Described veneer adopts the eucalyptus veneer that is formed by rotary cutting of eucalyptus log; Described core board adhesive is made of the component of following ratio: E0 urea-formaldehyde resin glue: flour: ammonium chloride: Iron red powder=1:0.4:0.006:0.001; the panel 2 adopts the panel of ice candy wood peeled from rock candy wood; the panel adhesive is coated between the core board 1 and the panel 2, and the panel The adhesive is made of the following components: E0 urea-formaldehyde resin glue:flour=1:0.5. The E0 urea-formaldehyde resin in the core board adhesive and the panel adhesive is made of the following components: formaldehyde: urea: melamine: accelerator Z-1: polyvinyl alcohol 20-99=1:0.725 :0.025:0.028:0.03.

[0033] The thi...

Embodiment 3

[0035] A eucalyptus glued fan blade board, comprising a core board 1 and panels 2 glued on both sides of the core board 1, the core board 1 is composed of three veneers, and core board glue is coated between two veneers Sticky agent; Described veneer adopts the eucalyptus veneer that is formed by rotary cutting of eucalyptus log; Described core board adhesive is made of the component of following ratio: E0 urea-formaldehyde resin glue: flour: ammonium chloride: Iron red powder=1:0.4:0.006:0.001; the panel 2 adopts the panel of ice candy wood peeled from rock candy wood; the panel adhesive is coated between the core board 1 and the panel 2, and the panel The adhesive is made of the following components: E0 urea-formaldehyde resin glue:flour=1:0.5. The E0 urea-formaldehyde resin in the core board adhesive and the panel adhesive is made of the following components: formaldehyde: urea: melamine: accelerator Z-1: polyvinyl alcohol 20-99=1:0.725 :0.025:0.025:0.028.

[0036]The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com